F-300

Pitot Tube Acrylic Flow Meter

An aquatics industry standard for over six decades, Blue-White’s F-300 Flow Meter is accurate and has reduced space requirements for installation. The aerodynamic pitot tube is designed for smooth fluid flow through the meter. There are four capture points resulting in no float bounce.

New features include:

- PVDF cap that won’t fade or crack

- PVDF float that won’t stick, is chemical resistant, and easy-to read-color

- Improved accuracy

Recommended Accessories:

F-300S, F-300SL Flow Switch and Sensor

Technical Overview:

GPM

2 - 1900

LPM

8 - 7200

PSI

75

Bar

5.2

Fahrenheit (°F)

190

Celsius (°C)

88

Body Material

Acrylic

Pipe Sizes

1”, 1¼”, 1½”, 2”, 2½”, 3”, 4”, 6”, 8”

Literature

F-300 Literature

Instruction Manuals

F-300 Instruction Manual – 80000-557Technical Data Sheets

F-300 | D-300 | U-300 Technical Data Sheet – 85000-071Quickstart Guides

F-300 Quickstart Guide – 80000-700Brochures

Blue-White Pool Flysheet - 80000-589

Flow Rate Calculator

Pool Flow Rate Calculator

Features

Model Variations:

- F-300 = Horizontal flow

- D-300 = Vertical downflow

- U-300 = Vertical upflow

- NSF 50 LISTED 1”, 1.25”, 1.5”, 2” (L2), 2.5”, 3”, 4”, 6”, and 8″ (L3) – Horizontal flow only

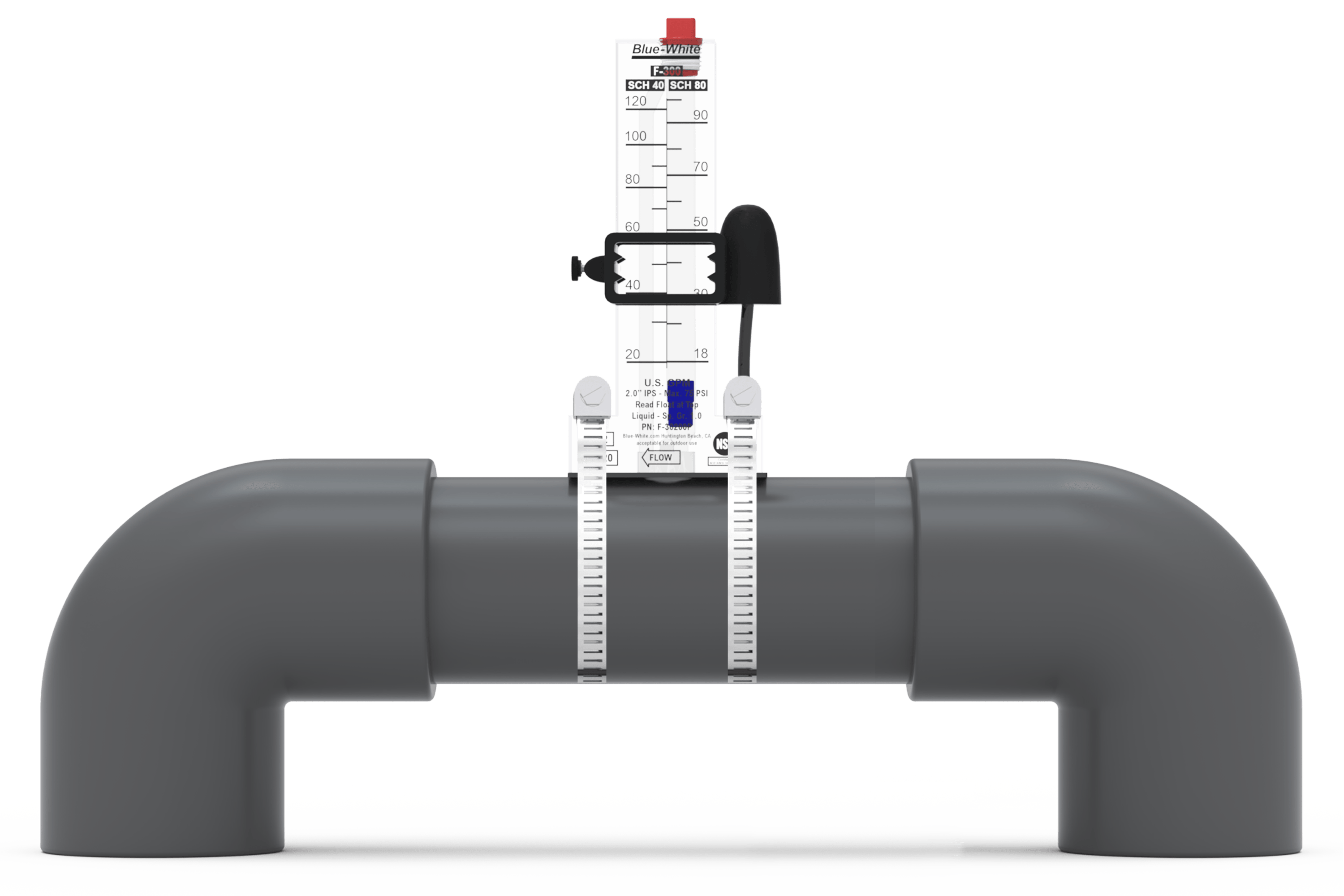

- Well suited for closed pipe installations

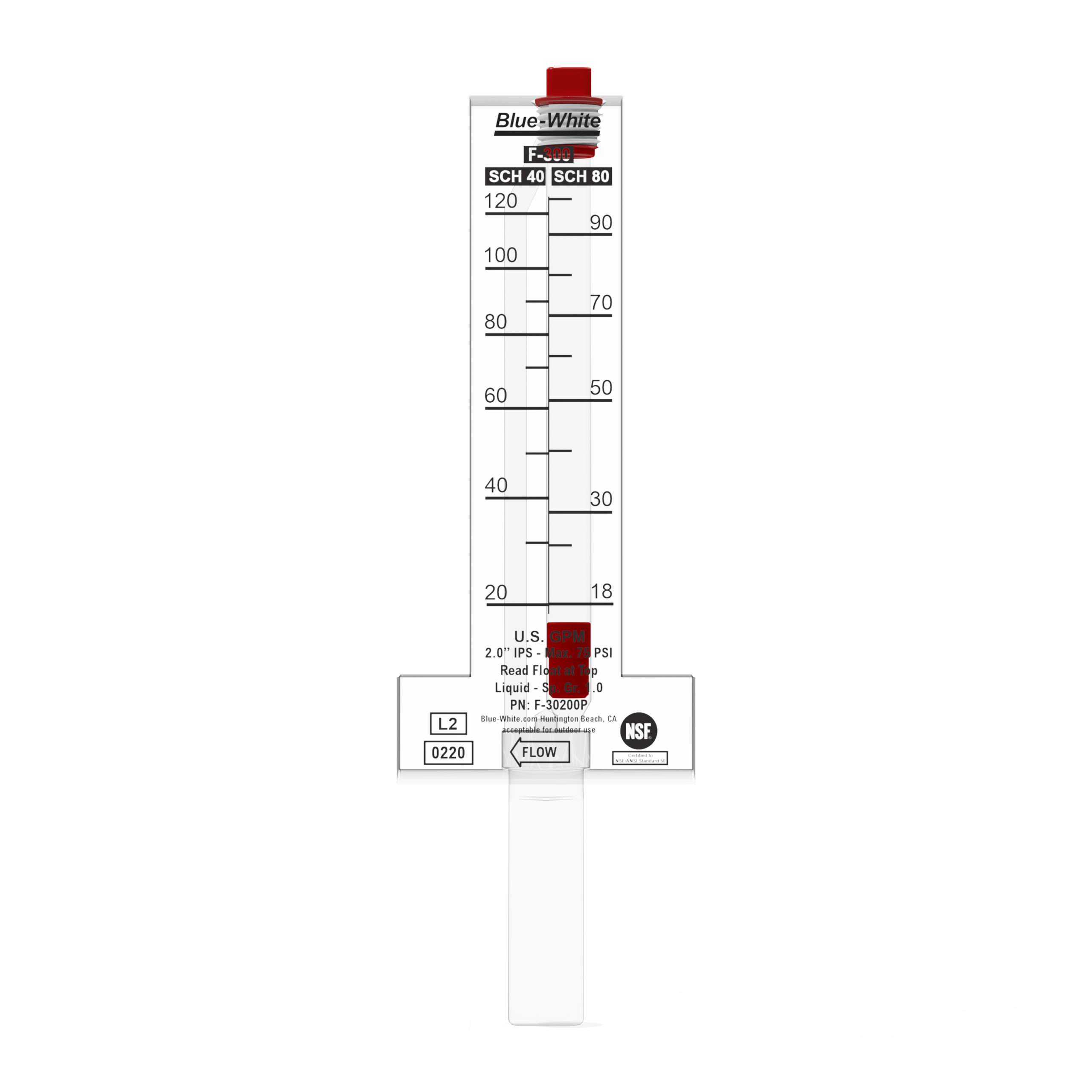

- Easy to read dual scale (SCH 40 / SCH 80), screen printed on both sides of the meter body

- Acceptable for outdoor installations (direct sunlight okay)

- Pitot Tube (impact tube) design makes it easy to install on existing pipe

- One-piece, machined acrylic meter body

- Included SS clamps and gasket seal

- For use on PVC (refer to literature)

What’s Included:

- Flowmeter x1

- Rubber Gasket x1

- Clamp x2

- Instruction Manual

Specifications

Horizontal Installation:

- 1″, 1.25″, 1.5″, 2″, 2.5″, 3″, 4″, 6″, 8″

Vertical Installation:

- 1½″, 2″

Max. Working Pressure:

- 75 PSI (5.17 bar) @ 70˚F (21˚C)

Max. Fluid Temperature:

- 190˚F / 88˚C @ 0 PSI

Full Scale Accuracy:

- +/- 5% (L2 Pipe sizes: 1”, 1.25”, 1.5” and 2”)

- +/- 10% (L3 Pipe sizes: 2.5”, 3”, 4”, 6”, and 8”)

Meter Body Material:

- Acrylic

Gasket Material:

- Neoprene

Float Material:

- PVDF

Connection Type:

- Saddle

Pipe Capability:

- PVC Schedule 40 and Schedule 80

Approx. Shipping Weight:

- 1” to 4” Pipe: 1 lb. (.454kg)

- 6” and 8” Pipe: 2 lb. (.907 kg)

Order Now

| Image | Catalog Number | Description | Price | Buy |

|---|

Meter Ranges

Horizontal Pipe Installation

Models for U.S. IPS SCH 40 & 80 Pipe (ASTM 1785)

| MODEL NO. | PIPE SIZE | PIPE MATERIAL | SCH 40 (GPM) | SCH 80 (GPM) |

|---|---|---|---|---|

| F-30100P | 1” IPS | PVC | 5 – 35 GPM | 4 – 26 GPM |

| F-30125P | 1 ¼” IPS | PVC | 9 – 50 GPM | 8 – 40 GPM |

| F-30150P | 1½” IPS | PVC | 10 – 70 GPM | 10 – 60 GPM |

| F-30200P | 2” IPS | PVC | 20 – 120 GPM | 18 – 100 GPM |

| F-30250P | 2½” IPS | PVC | 29 – 150 GPM | 25 – 130 GPM |

| F-30300P | 3” IPS | PVC | 45 – 240 GPM | 40 – 215 GPM |

| F-30400P | 4” IPS | PVC | 75 – 420 GPM | 70 – 375 GPM |

| F-30600P | 6” IPS | PVC | 170 – 1100 GPM | 160 – 1000 GPM |

| F-30800P | 8” IPS | PVC | 300 – 2200 GPM | 275 – 1950 GPM |

Horizontal Pipe Installation (Metric)

Models for METRIC Pipe (DIN 8062)

| MODEL NO. | PIPE SIZE | PN10 (LPM) | PN16 (LPM) |

|---|---|---|---|

| F-30032M | 32mm | 30 – 150 LPM | 30 – 130 LPM |

| F-30040M | 40mm | 70 – 310 LPM | 60 – 270 LPM |

| F-30050M | 50mm | 50 – 350 LPM | 50 – 300 LPM |

| F-30063M | 63mm | 100 – 475 LPM | 75 – 400 LPM |

| F-30075M | 75mm | 150 – 700 LPM | 150 – 600 LPM |

| F-30090M | 90mm | 200 – 850 LPM | 200 – 800 LPM |

| F-30110M | 110mm | 600 – 1800 LPM | 550 – 1600 LPM |

Verticle Pipe Installation

Models for U.S. IPS SCH 40 & 80 Pipe (ASTM 1785)

| MODEL NO. | PIPE SIZE | SCH 40 (GPM) | SCH 80 (GPM) |

|---|---|---|---|

| D-30150P | 1½” IPS | 10 – 60 GPM | 10 – 50 GPM |

| D-30200P | 2” IPS | 20 – 110 GPM | 20 – 100 GPM |

| U-30150P | 1½” IPS | 10 – 60 GPM | 10 – 50 GPM |

| U-30200P | 2” IPS | 20 – 110 GPM | 20 – 100 GPM |

Videos

Replacement Parts

| Image | Catalog Number | Description | Price | Buy |

|---|

Downloads

| Title | Size | Update Date | Download |

|---|---|---|---|

|

Aquatic Catalog 2024 – 80000-709 |

4.67 MB | April 16, 2024 | Download |

|

Aquatics Products Brochure |

10.94 MB | February 14, 2024 | Download |

|

F-300 | D-300 | U300 Installation Instructions – 80000-046 |

448.41 KB | February 8, 2022 | Download |

|

F-300 Instruction Manual – 80000-557 |

35.68 KB | February 8, 2022 | Download |

|

F-300 Metric Instruction Manual – 80000-592 |

53.16 KB | June 7, 2023 | Download |

|

F-300 Quickstart Guide – 80000-700 |

305.64 KB | April 16, 2024 | Download |

|

F-300 Technical Data Sheet – 85000-071 |

639.76 KB | April 15, 2024 | Download |

|

F-300M Metric Technical Data Sheet – 85000-070 |

6.32 MB | April 15, 2024 | Download |

|

Industrial Catalog 2024 – 80000-707 |

17.00 MB | April 16, 2024 | Download |

|

Industrial Products Brochure |

2.84 MB | February 20, 2024 | Download |

|

Municipal Products Brochure |

2.98 MB | February 14, 2024 | Download |