Variable Area Flow Meters

Blue-White® Variable Area Flow Meters

Variable Area Flow Meters (Rotameters) are a cost-effective solution for applications involving the measurement of industrial process water. Blue-White® offers direct-reading variable area flow meters to provide an accurate, safe, and economical method of measuring flow.

Explore Variable Area Flow Meters (Acrylic)

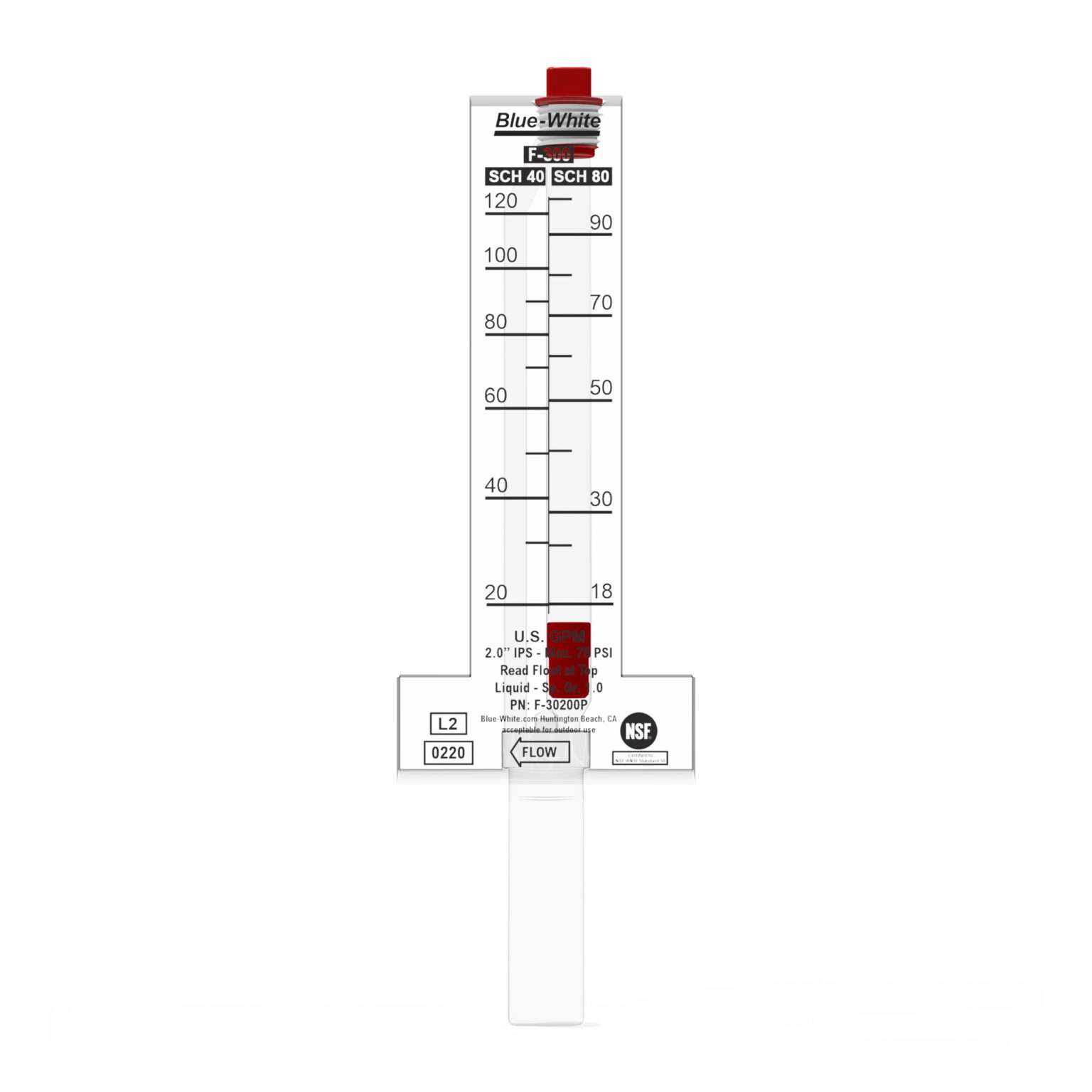

F-300

Pitot Tube Acrylic Flow Meter

| GPM | LPM |

|---|---|

| 2 - 1900 | 8 - 7200 |

| PSI | Bar |

| 75 | 5.2 |

| Pipe Sizes | |

| 1”, 1¼”, 1½”, 2”, 2½”, 3”, 4”, 6”, 8” | |

F-400

Acrylic Flow Meter

| GPM | LPM |

|---|---|

| .025 - 5 | .1 - 20 |

| PSI | Bar |

| 150 | 10.3 |

| Pipe Sizes | |

| ¼”, ⅜” , ½” F/NPT | |

F-410

Acrylic Flow Meter

| GPM | LPM |

|---|---|

| 1 - 20 | 4 - 80 |

| PSI | Bar |

| 150 | 10.3 |

| Pipe Sizes | |

| ¾”, 1” F/NPT | |

F-420

Acrylic Flow Meter

| GPM | LPM |

|---|---|

| 5 - 50 | 20 - 200 |

| PSI | Bar |

| 130 | 8.9 |

| Pipe Sizes | |

| 1” F/NPT, 1½” M/NPT | |

F-430

Acrylic Flow Meter

| GPM | LPM |

|---|---|

| 4 - 100 | 15 - 375 |

| PSI | Bar |

| 130 | 8.9 |

| Pipe Sizes | |

| 1½”, 2” F/NPT | |

F-550

Acrylic Flow Meter

| GPM | LPM |

|---|---|

| .025 - 20 | .1 - 75 |

| PSI | Bar |

| 250 | 17.2 |

| Pipe Sizes | |

| 1/4”, 3/8”, 3/4” and 1” male NPT | |

Explore Variable Area Flow Meters (Polysulfone)

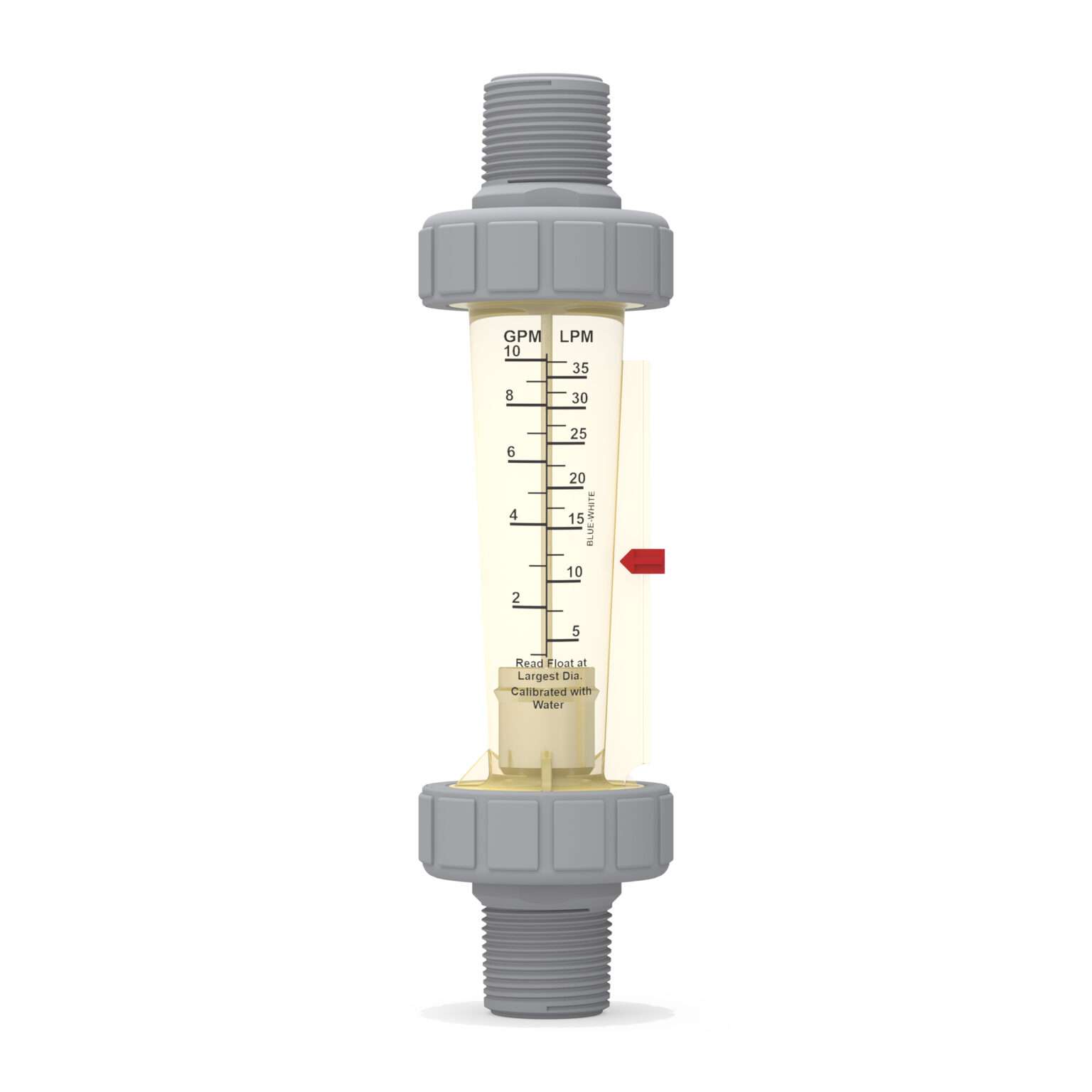

F-440

Polysulfone Flow Meter

| GPM | LPM |

|---|---|

| .025 - 10 | .1 - 37.5 |

| PSI | Bar |

| 175 | 12 |

| Pipe Sizes | |

| ⅜”, ½”, ¾” M/NPT | |

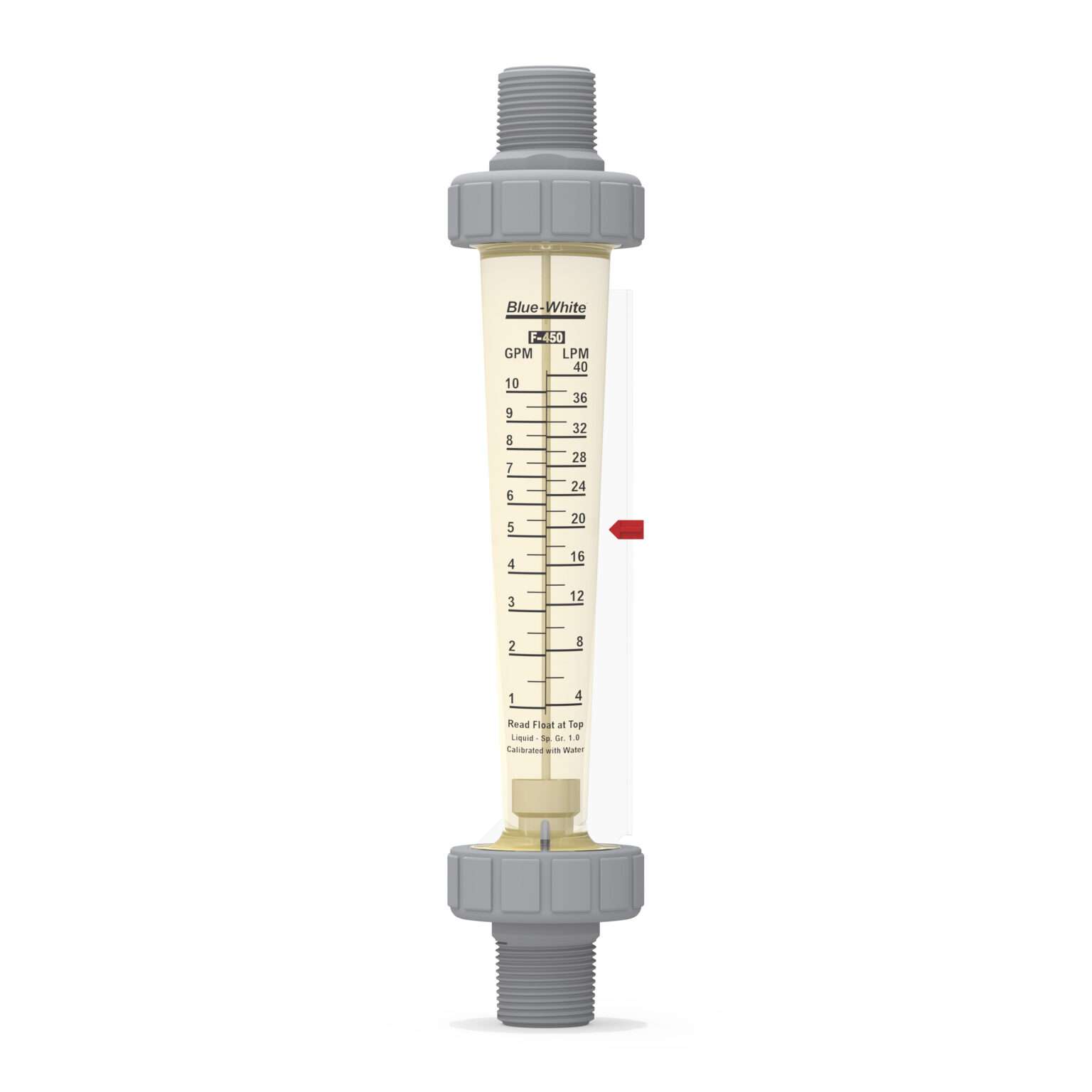

F-450

Polysulfone Flow Meter

| GPM | LPM |

|---|---|

| .1 - 10 | .4 - 40 |

| PSI | Bar |

| 175 | 12 |

| Pipe Sizes | |

| ⅜”, ½”, ¾” F/NPT | |

F-451

Polysulfone Flow Meter

| GPM | LPM |

|---|---|

| .5 - 40 | 2 - 155 |

| PSI | Bar |

| 150 | 10.3 |

| Pipe Sizes | |

| 1” F/NPT (Polysulfone), 1½” F/NPT (PVC) | |

F-452

Polysulfone Flow Meter

| GPM | LPM |

|---|---|

| 2 - 175 | 8 - 675 |

| PSI | Bar |

| 150 | 10.3 |

| Pipe Sizes | |

| 2” F/NPT | |

F-460

Polysulfone Flow Meter

| GPM | LPM |

|---|---|

| .1 - 5 | .4 - 20 |

| PSI | Bar |

| 150 | 10.3 |

| Pipe Sizes | |

| 1/2″ and 3/4″ female NPT fittings | |

F-461

Polysulfone Flow Meter

| GPM | LPM |

|---|---|

| 1 - 35 | 4 - 130 |

| PSI | Bar |

| 150 | 10.3 |

| Pipe Sizes | |

| 1″ female NPT fittings | |

F-462

Polysulfone Flow Meter

| GPM | LPM |

|---|---|

| 2 - 80 | 8 - 300 |

| PSI | Bar |

| 150 | 10.3 |

| Pipe Sizes | |

| 2″ female NPT fittings | |

Compare Flow Meters

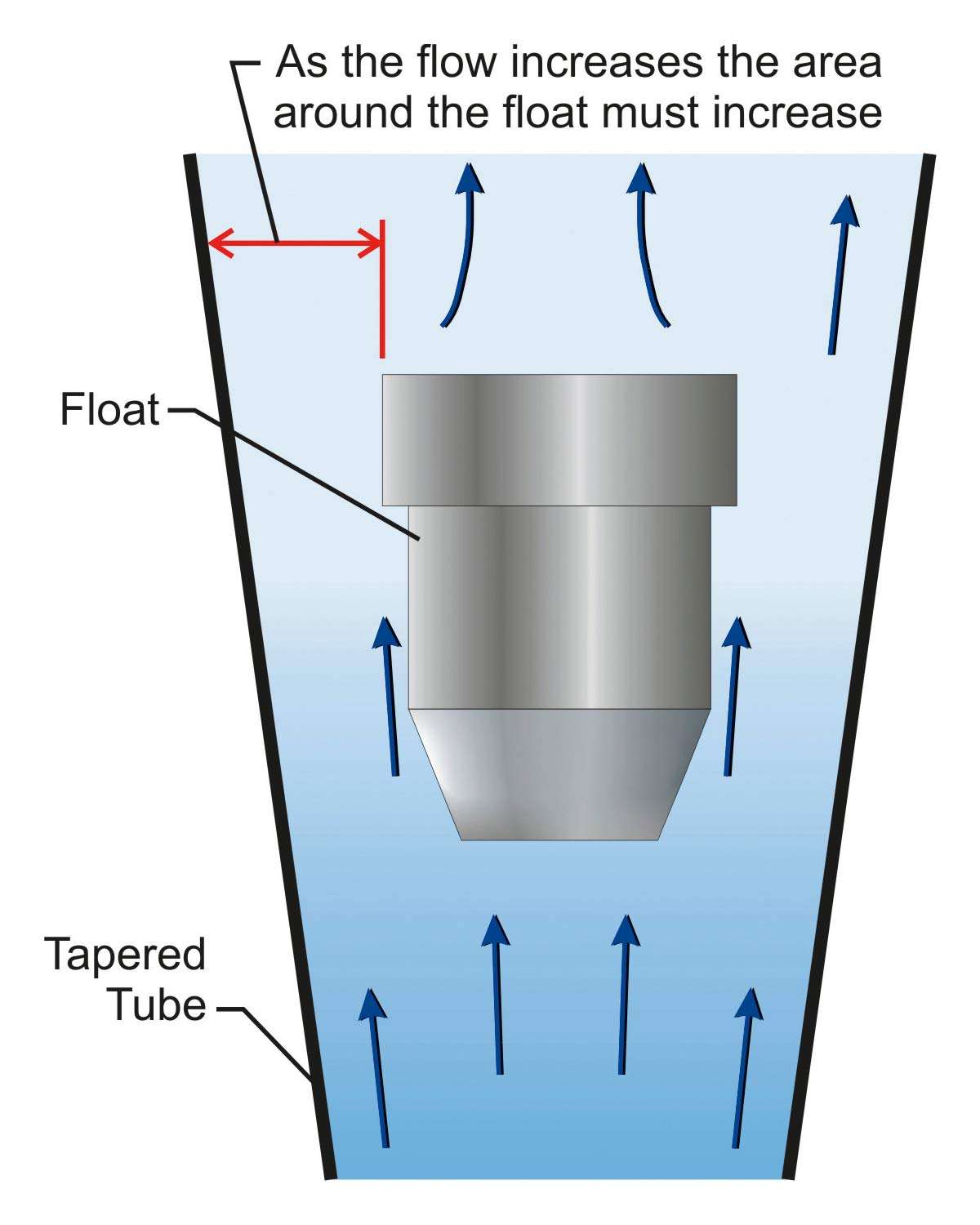

How do Variable Area Flow Meters Work?

Blue-White® Variable Area Flow Meters (rotameters) measure the volumetric flow of liquids. They have an orifice and a float that can move vertically inside a tube with an increasing diameter from bottom to top. As the fluid flows through the tube, it forces the float upward. The clearance space (annular area between the float and the tube wall) between the float and the tube increases as the float moves toward the top of the meter. The larger clearance area towards the top requires more fluid to force the float higher. The greater the flow, the higher the float is raised.

Advantages of a Variable Area Flow Meter

-

Cost effective

Low cost compared to other flow measurement devices

-

Reliable

Trouble-free operation ensures years of accurate flow measurement and repeatability

-

Simple

Very easy to install and maintain

-

Flexible

No power required, which means they can be used virtually anywhere

Applications

- Wastewater Treatment

- Potable Water Treatment

- RO Water Systems

- Semiconductor Fabrication

- Commercial RO Water Systems

- Commercial Aquariums

- Industrial Process

Explore Articles

Variable Area Flow Meter FAQ

A variable area flow meter is a type of differential pressure flow meter. Variable area flow meters are simple and versatile devices that operate at a relatively constant pressure drop and measure liquids, gases, and steam flow.

One of the earliest and most well-known flow measurement principles is the variable area flow measurement approach. As a result, of all the flow-measuring technologies now on the market, variable area flowmeters (commonly referred to as rotameters) have one of the largest installed bases. This technology has several benefits, including dependability, accuracy, simplicity of installation, and readability. Also, these meters are frequently used because the measurement method is mechanical in nature and can be used in instances without power.

The following are the three main types of variable area flow meters:

Glass Tube Variable Flow Meters

The glass tube indicating type is the most common variable area flow meter form. The float is machined from metal, glass, or plastic, while the tube is made from borosilicate glass. The meter’s scale can be calibrated to read air or water directly, or it may have a scale that reads a percentage of range or an arbitrary scale that can be used with conversion equations or charts.

Metal Tube Flow Meters

When strong working pressure, a wide temperature range, water hammering, or other pressures would break glass metering tubes, stainless steel, metal tube flow meters are utilized. The majority of fluids, including corrosive liquids and gasses, can be used with metal tube flow meters.

Plastic Tube Variable Flow Meters

Several versions of variable area flow meters use plastic tubes because of their inexpensive cost and great impact strength. Usually made of polycarbonate, they have either metal or plastic end fittings. While installing plastic end fittings, care must be taken to prevent thread distortion. For applications where metal wetted parts cannot be tolerated, for as with deionized water or corrosives, meters with an all-plastic structure are available.