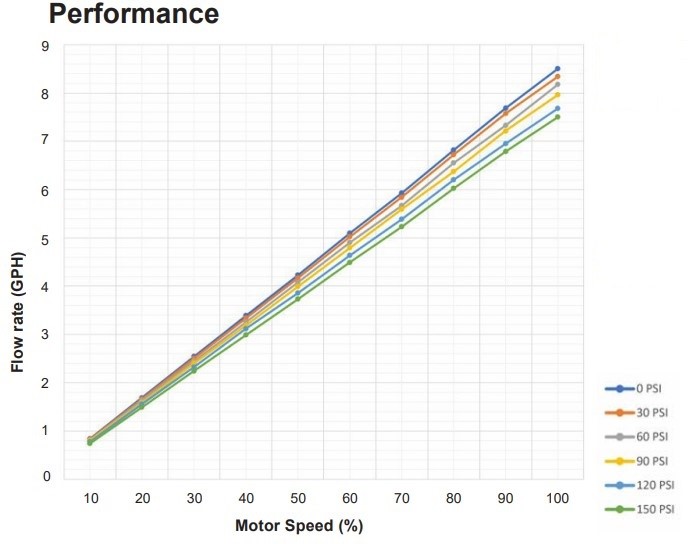

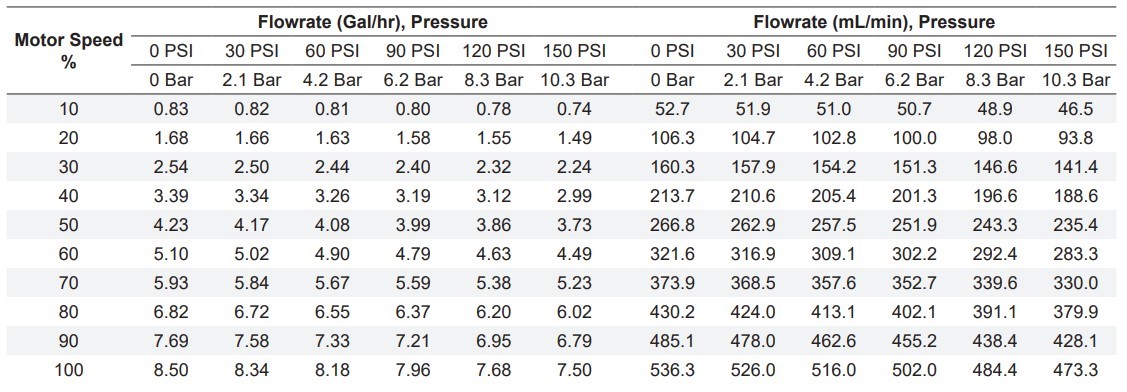

Performance

Maximum Flow/Pressure:

- 7.50 gph at 150 PSI

- 7.68 gph at 120 PSI

- 7.96 gph at 90 PSI

- 8.18 gph at 60 PSI

- 8.34 gph at 30 PSI

- 8.50 gph at 0 PSI

Maximum Fluid Temperature: 185 °F (85 °C)

Maximum Viscosity: 1,000 Centipoise

Maximum Suction Lift: 20 ft

Electrical and Controls

Electrical Power Requirement: 100 to 240VAC, 50/60Hz

Power cord options available (6 feet length):

- 115VAC 50/60HZ, NEMA 5/15 plug (U.S.) – (choose when specifying pump model)

- 220VAC 50/60HZ ,CEE 7/V11 plug (EU) – (choose when specifying pump model)

- 230VAC 50/60HZ, NEMA 6/15 (U.S.) – (ordered separately)

- 240VAC 50/60HZ, AS 3112 plug (Australia / New Zealand) (ordered separately)

- 230VAC 50/60HZ, BS 1363/A plug (UK) (ordered separately)

Signal Connectors: M12 – 5 pin (IP67 rated connectors on “V” models)

Inputs:

- 4-20 mA – fully configurable

- Stop/Start Dry Contact Closure (Configurable for N.O. or N.C.)

Outputs:

- 4-20 mA output – non-scalable

- Alarm Output – DFD (Diaphragm Failure Detection) and FVS (flow verification – flow sensor ordered separately)

- Motor On Status – open collector output

Motor: Brushless DC, 50W, 2,000:1 Turndown, Continuous Duty

Materials of Construction

- Pump Head: PVDF

- Manifolds: PVDF

- Adapters: PVDF

- Valve Cartridges: PVDF

- Valve Balls: Ceramic (optional Teflon)

- Valve Seats: TFE/P (optional EP)

- Diaphragm: DiaFlex (optional Flex-A-Prene)

- Enclosure: NEMA 4X (IP66) Valox

Dimensions and Weights

- Maximum Overall Dimensions: 9.5” W x 9.5” H x 10.4” D (24.1 W x 24.1 H x 26.4 D cm)

- Product Weight: 8.5 Lb. (3.8 Kg)

- Approximate Shipping Dimensions: 10.5” W x 11.75” H x 13” D (26.7 W x 29.8 H x 33 D cm)

- Approximate Shipping Weight: 15.5 lb. (7.0kg)

Agency Listings

- CE

- cETLus

- RoHS Compliant

FAQs

Frequently Asked Questions

CD1 Specifications

- Is the CD1 pump NSF 61?

No. The CD1 pump is not rated NSF 61.

Is the CD1 rated NEMA 4X?Yes. The CD1 pump is rated NEMA 4X.

Does CD1 have 4-20 ma capability?The CD1 pump can be ordered as a CD1F or CD1V. The CD1V model has 4-20ma input speed control (scalable) and 4-20ma output (motor speed - full scale). The CD1F model does not have 4-20ma capabilities.

What is the maximum pressure CD1 can handle?The maximum pressure of the CD1 pump is 150 psi (10.3 bar).

Max Feed Rate listed is 8.50 GPH. My output is a lot less. Why?The maximum feed rate of the pump is determined by pumping water at a temperature of 72°F into the atmosphere, with a 5-foot suction at sea level. However, factors such as viscosity, elevation of operation, suction lift, fluid temperature, and injection pressure can affect the actual feed rates. To accurately calibrate the pump to the specific installation conditions, it is recommended to conduct a volumetric test.

What is standard pumphead connection type? Are other options available?Std connection type is 3/8" od tube compression. Optional Kit-C5M = 1/2 mnpt, Kit-C5B = 1/2" hose barb.

What does Hz mean? “pulses per second,” “frequency,” or “Inside Diameter”.Hertz (Hz) is unit a measure representing cycles per second (1/sec). For flowmeters, this correlates to pulses/second. The flowmeter will produce a frequency of pulses per second, where each pulse is equal to a certain volume of solution.

What material are the 3/16″ stainless steel screws?It's a typo, it should read 316 stainless steel.

What is PA12?PA 12 (also known as Nylon 12 or polyamide 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties. And more recently, PA 12 has been adopted as a common 3D printing material for creating functional parts and prototypes.

What is TFE/P?TFE/P is a copolymer of tetrafluoroethylene and propylene with a fluorine content of app. 54%. This material is unique due to its resistance to petroleum products, steam, and phosphate-esters. In some respects it exhibits media compatibility properties similar to ethylene propylene and fluorocarbon. The compression set resistance at high temperatures is inferior to standard fluorocarbons. Service temperatures are -5°C (25°F) to +204°C (+400°F).

TFE/P provides improved chemical resistance to a wide spectrum of automotive fluids and additives. It is resistant to motor oils of all types, engine coolants with high level of rust inhibitors, extreme pressure (EP) gear lubricants, transmission and power steering fluids, and all types of brake fluids including DOT 3, mineral oil, and silicone oil. TFE/P is ideal for heat transfer media, amines, acids and bases, as well as hot water and steam up to +170°C (+340°F).

What is Hastelloy C-276?What is DiaFlex material?DiaFlex® Diaphragms

Blue-White’s® PVDF diaphragms, used in our CHEM-FEED® Diaphragm type Chemical Metering Pumps, are manufactured in our factory to ensure a quality product. DiaFlex® features an innovative single-layer design that exhibits zero breakdowns or delamination. DiaFlex® is designed to last the life of the pump which greatly reduces downtime and maintenance. The PVDF composition of both the pump head itself and the diaphragm ensures excellent chemical compatibility. DiaFlex® is available in three sizes to accommodate varying flow rates.

- The first single-layer injection molded PVDF diaphragm

- Zero breakdown

- Zero delamination

- 100% in-house manufacturing

- Longer lasting diaphragm

- Single wetted pump head material

- Patented design

What is Flex-A-Prene material?Flex-A-Prene® Diaphragm

Blue-White’s® Flex-A-Prene® diaphragm is manufactured from a type of Thermoplastic Elastomer (TPE) or Thermoplastic Rubber specifically designed to offer long life in chemical metering pump applications and to provide superior chemical resistance against most water treatment chemicals. The material exhibits remarkable memory properties resulting in excellent flow repeatability in diaphragm pumping applications.

- Flex-A-Prene® diaphragm is capable of operating against system pressures as high as 150 PSI (10.3 bar) and continuous operating temperatures as high as 185F (85C).

- Flex-A-Prene® material fully complies with FDA 21 CFR, 177.2600 criteria for food contact.

- Flex-A-Prene® is a registered trademark of Blue-White Industries.

Enclosure specs are “NEMA 4X, Valox, PA12” what do these mean?Valox:VALOX are a semi-crystalline family of PBT, PET and blends with Polycarbonate (PC), offering an outstanding mix of value added properties for a variety of applications. Blue-White uses VALOX 420SE0. VALOX 420SE0 Polybutylene Terephthalate (PBT) resin is a 30% glass fiber reinforced, injection mold grade material. This brominated flame retardant PBT has a UL V0 and 5VA rating.

PA12 is Polyamide 12 or also known as Nylon 12. PA12 is a general use plastic with broad applications and is known for its toughness, tensile strength, impact strength, and ability to flex without fracture.

The maximum suction lift is stated as 20 ft at 0 psi. what does it mean “0 psi”?0 psi means at 0 psig. PSIG stands for pounds per square inch gauge. It is a unit of pressure that is used to measure the pressure of a fluid above atmospheric pressure. Atmospheric pressure is the pressure exerted by the weight of the air at sea level. At sea level, atmospheric pressure is approximately 14.7 psi.

What operating voltage is my pump? how do I change the operating voltage?The CD1 and MD1 pumps can be operated with a wide range of incoming voltages, from 96 to 264 VAC at 50 or 60 Hz. This is because the pumps are equipped with a self-adjusting voltage feature that automatically adjusts the pump's output voltage to match the incoming voltage. This means that there is no need to manually change the operating voltage of the pump, regardless of where it is being used.

How many strokes per minute?The CD1 and MD1 pumps have a maximum strokes per minute of 200 strokes per minute (SPM).