Peristaltic Pump Delivers Simple,

Precise Dosing of Sodium Hypochlorite for

Successful Water Disinfection

Chlorine has been used to disinfect water in the U.S. since the early 1900s, and it remains the most frequently used water and wastewater disinfectant worldwide due to its low cost and effectiveness at deactivating a wide range of pathogens.

The two most common chlorine products for these applications are chlorine gas (Cl2) and sodium hypochlorite (NaOCl), a.k.a. bleach. For the most part, both chlorine compositions function the same way, in that they dissolve in water to form free chlorine in the form of hypochlorous acid (HOCl) and hypochlorite ion (OCl−). Treatment plants target the same parts per million of free chlorine regardless of which chlorine source is used.

Despite this, they are two very different products. Choosing which chlorine chemical to use is an important decision among water and wastewater managers, and requires balancing the overall costs, safety procedures, and more.

Safety Considerations

Risk Management Plans (RMPs) driven by regulation and required when gas chlorine is in use can be costly to develop, implement and keep updated.

Sodium hypochlorite may be a safer alternative to Chlorine gas, but the chemical should still be treated with respect, and although safety protocols may not be mandated, they should still be in place.

Operator Comfort

Closely related to safety is the issue of operator comfort. Although more potent than household bleach, sodium hypochlorite is familiar in many ways for operators. Still, it’s important to note that sodium hypochlorite should never be stored near other chemicals, particularly acids. If there is a sodium hypochlorite spill or leak proper PPE should be worn until the danger is mitigated.

Another source of comfort when using sodium hypochlorite is familiarity with the equipment used to deliver the chemical to the water. Simple to use metering pumps will dose the proper amount of sodium hypochlorite into the system.

Chlorine gas, on the other hand, uses specialized equipment to administer the gas from the cylinder to the water. Operators may require comprehensive training to properly operate this equipment.

Cost Comparison

Both chlorine gas and sodium hypochlorite are affordable disinfectants, although the former is slightly cheaper from a raw chemical cost standpoint. The metering equipment used to dispense chlorine gas is more costly.

The two most used types of chemical metering pumps for dispensing liquid chlorine are peristaltic and diaphragm types of chemical feed pumps.

Peristaltic pumps are extremely effective when pumping fluids that contain trapped gases because they are not affected by air bubbles. The bubbles simply move through the pump tubing as the pump maintains a constant rate of flow with no potential for vapor lock, and peristaltic pumps do not lose prime. Due to this characteristic, Peristaltic pumps have been widely accepted as the preferred technology in many water and wastewater treatment applications.

In contrast, the intermittent pumping action of diaphragm pumps, specifically during the suction phase of the cycle, can cause gas build-up. This buildup of gases can lead to vapor lock and the pump may lose prime.

It should also be taken into consideration that other than occasional pump tube replacement, peristaltic units do not require regular maintenance. Diaphragm pumps, on the other hand, require ongoing maintenance as valves and pump heads must be regularly cleaned.

In conclusion, Water and Wastewater Treatment Managers have achieved excellent results using sodium hypochlorite to sanitize water and wastewater, and peristaltic pumps have proven to be an excellent choice for dosing liquid chlorine.

The simplest and most effective delivery method for dosing Sodium Hypochlorite is Chemical Metering Pumps. The two most used types of chemical metering pumps for this purpose are peristaltic and diaphragm chemical feed pumps.

Peristaltic pumps are extremely effective when pumping fluids that contain trapped gases because they are not affected by air bubbles. The bubbles simply move through the pump tubing as the pump maintains a constant rate of flow with no potential for vapor lock, and peristaltic pumps do not lose prime. Because of these characteristics, peristaltic pumps have been widely accepted as the preferred technology in many water and wastewater treatment applications.

In contrast, the intermittent pumping action of diaphragm pumps, specifically during the suction phase of the cycle, can cause gas build-up. This buildup of gases can lead to vapor lock and the pump may lose prime.

Also to be taken into consideration is that, other than occasional pump tube replacement, peristaltic units do not require regular maintenance. Diaphragm pumps, on the other hand, require ongoing maintenance as valves and pump heads must be regularly cleaned.

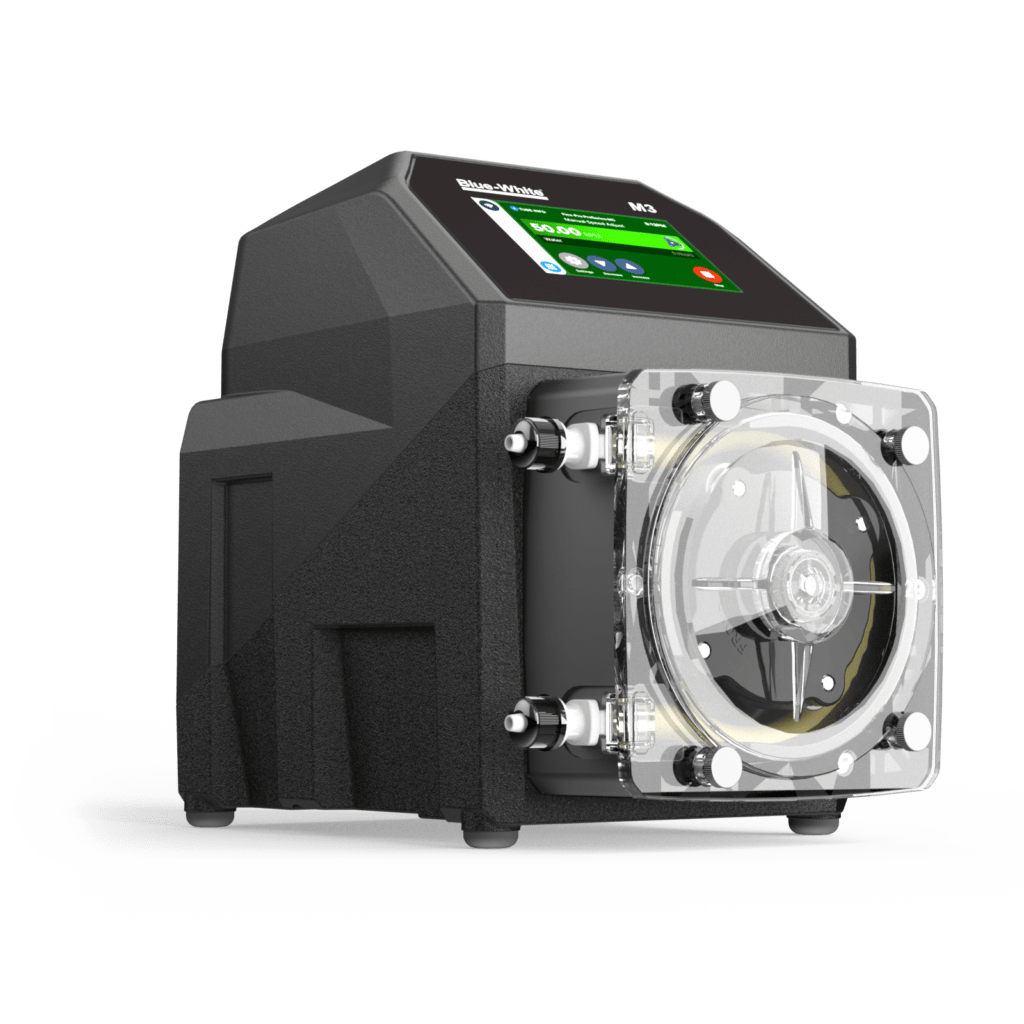

For these reasons we believe a Peristaltic Dosing Pump are the best metering pump choice for dispensing Sodium Hypochlorite, specifically a Blue-White® Industries M3 peristaltic dosing pump.

FLEXFLO® M3 Chemical Metering Pumps dependably deliver smooth and accurate chemical dosing to the system. Operators appreciate the pump’s bright, easy-to-access, and highly responsive 5-inch display screen, the intuitive screen is as simple to work as a cell phone and features easily recognizable icons.

FLEXFLO M3 pumps have a broad 10,000:1 turndown ratio to meet a vast range of dosing requirements, and they’re equipped with a brushless DC motor for trouble-free and energy-efficient service.

M3 remote control signal options include Pulse, 4-20mA, Modbus TCP, EtherNet IP, and PROFIBUS for enhanced supervision and automation for critical metering and transfer applications.

Consider FLEXFLO M3 for Simple, Accurate and Effective Dosing of Sodium Hypochlorite and other Treatment Chemicals.

Written by:

Blue-White® Industries

714-893-8529