CD1

CHEM-FEED® Multi-Diaphragm Metering Pump

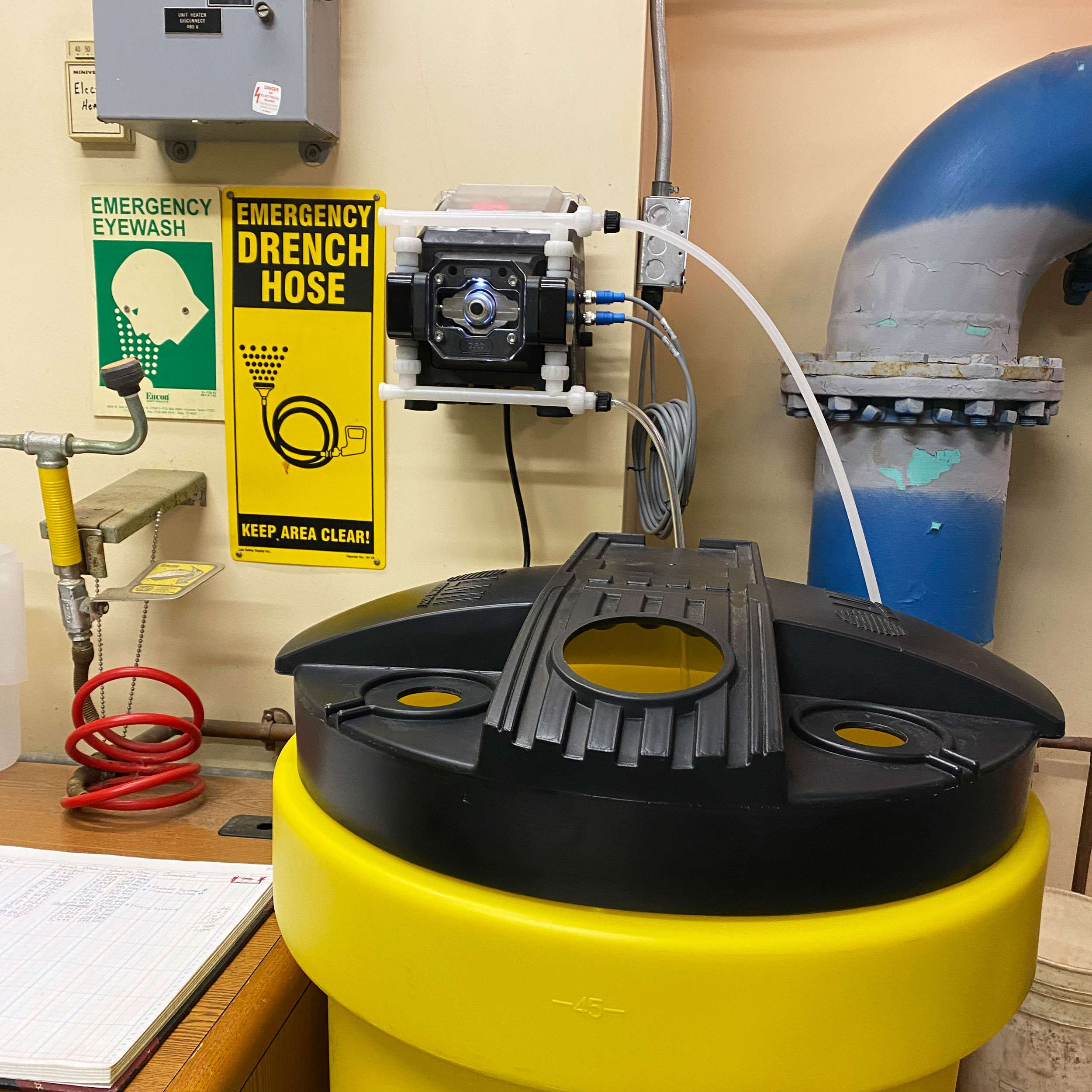

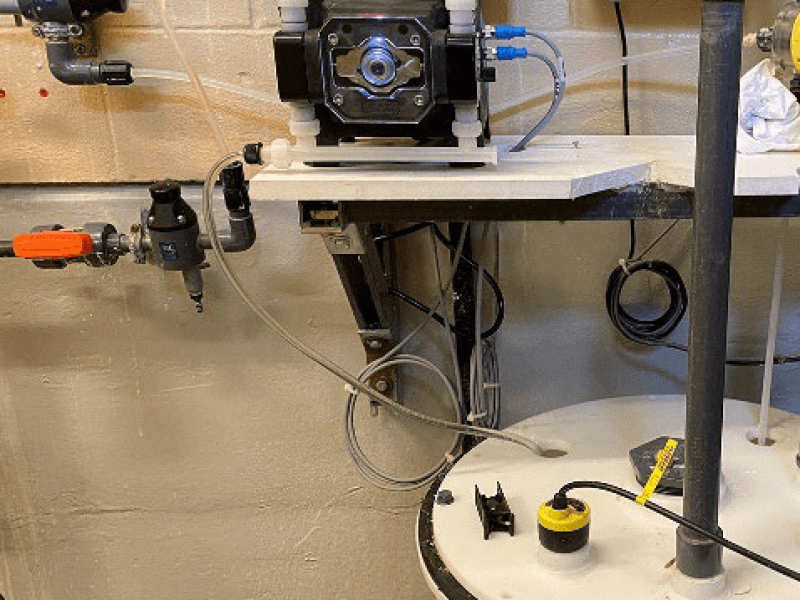

The CD1 delivers smooth, continuous chemical feed even when injecting fluids that off-gas. Its cutting-edge Hyperdrive Technology alternates pumping action between two diaphragms, minimizing vapor lock risks. Now, with the standard Automatic Degassing Valve (ADV) System on our CD1 pumps, we’ve further reduced vapor lock risks and eliminated the need for external degassing components.

The exclusive DiaFlex® Diaphragms last the life of the pump, saving on rebuild costs.

Technical Overview:

GPH

.004 - 8.5

LPH

.016 - 32.2

mL/min

.268 - 536.3

Pressure

150 PSI (10.3 Bar)

Enclosure Rating

NEMA 4X (IP66)

Standards

CE, cETLus, RoHS

Control Methods

Manual, Remote Analog

Power Supply

100 to 240VAC-50/60Hz

Literature

CD1 Literature

Instruction Manuals

CD1 Instruction Manual – 80000-610Technical Data Sheets

CD1 Technical Data Sheet – 85000-154Brochures

CD1 Brochure – 80000-710Catalog

Industrial Catalog 2023

3D Visualizer

Features and Benefits

Features

Benefits:

- Exclusive Hyperdrive technology allows for smooth chemical feed – Patent Pending

- Dual Diaphragm with full stroke technology will not lose prime, ideal for pumping chemicals that off-gas (Peracetic Acid, Sodium Hypochlorite)

- Can pump chemicals continuously, like a peristaltic pump, without the need for tube assemblies

Communication & Interface:

- Input: Remote Start/Stop: Non-powered dry contact closure for remote start/stop

- Input: Compatible with Flow Verification Sensors S6A and Micro-Flo

- Output: Alarm relay 250V / 3A

- Output: Motor On / Off single solid-state

- SCADA Inputs/Outputs include: 4-20mA. (Included with CD1V only)

Superior Design:

- 2 Year Warranty

- Energy-efficient BLDC motor will not overheat

- Snap-in-place wall and floor mounting bracket – Patent pending

- DiaFlex® diaphragm design will last the life of the pump, eliminates the need for expensive rebuild kits – Patented

- The Automatic Degassing Valve (ADV) System technology eliminates vapor lock risks and the need for external degassing components.

- Manifold design allows for multiple configuration possibilities – suction and discharge ports can be positioned on the left and right side of the pump

Safety Features:

- Diaphragm Failure Detection (DFD) Senses diaphragm rupture by detecting chemical in the pump head. No false triggering – Patented

- Lockout feature prevents any unwanted tampering – Patent pending

- Display shield to protect controls from harsh environments

Optional Components Available:

- Elbow Adapter Kits

- Elbow Connectors – ½” Male NPT, ½” Hose Barb, ⅜” Tube Compression

- O-rings – AFLAS, EP

What’s Included:

- CD1 Multi-Diaphragm Metering Pump

- Discharge injection fitting with check valve

- Suction tube – clear PVC – 5′ length (3/8″ OD, 1/4″ ID)

- Suction foot valve / strainer

- Suction ceramic weight

- Discharge tube – opaque polyethylene – 5′ length (3/8″ OD, 1/4″ ID)

- Mounting hardware kit

- Display shield

Output

| Motor Speed % | 0 PSI (0 bar) | 30 PSI (2.1 bar) | 60 PSI (4.2 bar) | 90 PSI (6.2 bar) | 120 PSI (8.3 bar) | 150 PSI (10.3 bar) |

| GPH (mL/min) | ||||||

| 10% | 0.83 (52.7) | 0.82 (51.9) | 0.81 (51) | 0.8 (50.7) | 0.78 (48.9) | 0.74 (46.5) |

| 20% | 1.68 (106.3) | 1.66 (104.7) | 1.63 (102.8) | 1.58 (100) | 1.55 (98) | 1.49 (93.8) |

| 30% | 2.54 (160.3) | 2.5 (157.9) | 2.44 (154.2) | 2.4 (151.3) | 2.32 (146.6) | 2.24 (141.4) |

| 40% | 3.39 (213.7) | 3.34 (210.6) | 3.26 (205.4) | 3.19 (201.3) | 3.12 (196.6) | 2.99 (188.6) |

| 50% | 4.23 (266.8) | 4.17 (262.9) | 4.08 (257.5) | 3.99 (251.9) | 3.86 (243.3) | 3.73 (235.4) |

| 60% | 5.1 (321.6) | 5.02 (316.9) | 4.9 (309.1) | 4.79 (302.2) | 4.63 (292.4) | 4.49 (283.3) |

| 70% | 5.93 (373.9) | 5.84 (368.5) | 5.67 (357.6) | 5.59 (352.7) | 5.38 (339.6) | 5.23 (330) |

| 80% | 6.82 (430.2) | 6.72 (424) | 6.55 (413.1) | 6.37 (402.1) | 6.2 (391.1) | 6.02 (379.9) |

| 90% | 7.69 (485.1) | 7.58 (478) | 7.33 (462.6) | 7.21 (455.2) | 6.95 (438.4) | 6.79 (428.1) |

| 100% | 8.5 (536.3) | 8.34 (526) | 8.18 (516) | 7.96 (502) | 7.68 (484.4) | 7.5 (473.3) |

Specifications

Maximum Working Pressure

- 150 psig (10.3 bar)

Maximum Fluid Temperature

- 185 °F (85 °C)

Maximum Ambient Temperature

- 14 °F to 115 °F / -10 °C to 46 °C

Maximum Viscosity

- 1,000 Centipoise

Maximum Suction Lift

- 20 ft. at 0 PSI

Operating Voltage Range

- 100 to 240VAC-50/60Hz

Power Cord Options

- 115V50/60Hz (0.6A max.) = NEMA 5/15 (USA)

- 230V50/60Hz (0.3A max.) = NEMA 6/15 (USA)

- 220V50/60Hz (0.3A max.) = CEE 7/VII (EU)

- 240V50/60Hz (0.3A max.) = AS 3112 (Australia/New Zealand)

- 230V50/60Hz (0.3A max.) = BS 1363/A (UK)

Motor

- Brushless DC, 50W

Duty Cycle

- Continuous

Turndown Ratio

- 2,000:1, (0.05% – 100%) Max rpm = 100

Maximum Overall Dimensions

- 7-1/4” W x 9” H x 10” D (18.5 W x 22.9 H x 25.2 D cm)

Product Weight

- 8.5 lb. (3.8 Kg)

Approximate Shipping Dimensions

- 10-1/2” W x 13 3/4” H x 11” D

Approximate Shipping Weight

- 15.5 lb. (7.0 Kg)

Enclosure

- NEMA 4X (IP66), Valox® (PBT) & PA12

RoHS Compliant

- Yes

Standards

- cETLus, CE

Videos

Watch Now

Watch Now

Watch Now

Watch Now

Watch Now

Related Case Studies

Accessories

Replacement Parts

| Image | Catalog Number | Description | Price | Buy |

|---|