Aquatics

A-100NA

Operation

Priming the Pump

Before priming the pump, or starting the pump, be sure that all suction and discharge lines are connected properly and that proper valves are open.

The pump can be primed by turning the Power Switch to “ON”, and then running the pump at 100% speed. The pump can be stopped at any time by turning the power switch to “OFF”.

If the pump does not prime, check the suction line for clogs, obstructions, or leaks. Make sure all appropriate valves are open.

Manual Operation

To run the pump, simply switch the pump to “ON” and adjust the speed as desired using the control dial knob. The A-100NA has a single speed motor. Flow is adjusted by a cycle timer. The total-time cycle is factory preset and is not user adjustable. The on-time cycle is adjustable from 5% to 100% of the total cycle time (A-100NA timer adjusts from .3 to 60 seconds with total time cycle of 60 seconds).

When the motor is running, the A-100NA flow will be near-continuous. To stop the pump, press the power switch to “OFF”.

The pump can only be turned on/off remotely by turning incoming power off and on, while the power switch remains in the “ON” position.

Calibration

To ensure the most accurate pumping, a pump calibration is recommended prior to operating the pump. The A-100NA pump flow rate will vary depending on the suction line conditions. Calibrate the pump with actual suction line conditions.

To calibrate the pump:

- Connection tubing and open valves on the suction side of the pump to represent actual suction lines conditions.

- Set up discharge and open discharge valves to dispense into calibration column/cylinder.

- Prime to the pump so that the calibration column begins to fill. Stop the pump and note the solution level in the calibration column.

- Run the pump at 100% speed for 1 minute.

- Record the flow difference in the calibration cylinder.

- Calculate the flow rate by dividing the flow by the time. For example, if the pump runs for 1 minute, and the flow difference is 30 ml, then divide 30ml by 1 minute. The flowrate is 30 ml/min.

- For best accuracy, run more than one calibration to check results, or run another calibration at a different pump speed.

Calibration results should be similar to the flow rating for the pump tube, but can vary depending on chemical composition, suction lift, viscosity, temperature, and other conditions.

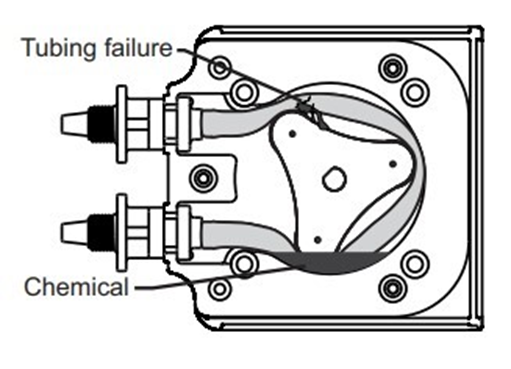

Tube Failure Detection (TFD)

The A-100NA pump is equipped with leak-detection located inside the pump head. If a tube fails or leaks for any reason, the chemical will trigger the sensor, stop the pump, and activate an alarm (if option is added and wired.)

This patented system is capable of detecting the presence of a large number of chemicals including Sodium Hypochlorite (Chlorine), Hydrochloric (muriatic) Acid, Sodium Hydroxide, and many others.

The system will not be triggered by water (rain, condensation, etc.) or silicone oil (roller and tubing lubricant). If the system has detected a chemical, the pump tube must be replaced, and the pump head and roller assembly must be thoroughly cleaned. Remove the front cover to replace the tube and roller. Failure to clean the pump head properly will void the warranty.

See this video on proper tube replacement. https://www.youtube.com/watch?v=NqhrR2Vs1OI&t=69s

Confirm Chemical Detection – To determine if your chemical will be detected by the system, remove the pump tube and roller assembly. Place a small amount of the chemical in the bottom of the pump head – just enough to cover the sensors.

Turn on the pump. If the TFD system detects the chemical, the pump will stop after a five-second confirmation period. If the TFD system does not detect the chemical, the pump will continue to run after the confirmation period.

Carefully clean the chemical out of the pump head, being sure to remove all traces of chemical from the sensor probes.

- Ask me a question!