Reliable and consistent performance

Blue-White’s peristaltic tubing provides consistent and reliable performance. With our quality assurance system in place, you can have confidence that our tube assemblies offer excellent tube life, and the capacity to deliver accurate and repeatable chemical feed.

Long Lasting

Less Waste

Clog-free Operation

Easy Re-order

Endless Connections

Versatile Application Capabilities

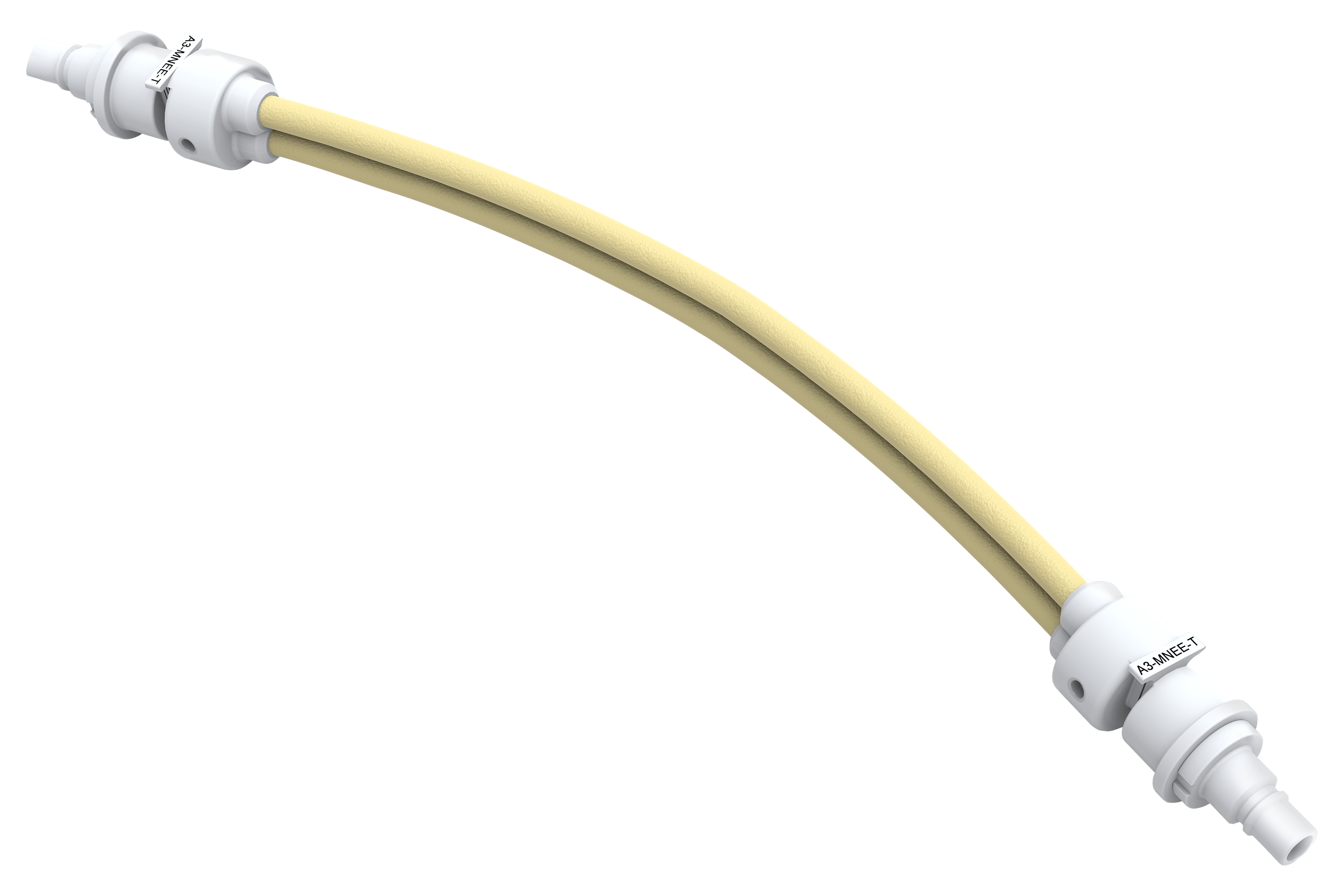

Innovative Tube Design for total reliability and longer maintenance intervals.

Fittings are mechanically spin-welded onto the tubing unit, making a clean seamless connection.

The dual-channel construction allows for higher flow rates at higher pressures and increased tube life.

Printed mode numbers can be easily viewed through the pump head while in full operation.

Select Your Tube

Flex-A-Prene® tubes are uniquely engineered and designed for optimum performance and pressure capability. It is an excellent material for most water treatment applications. Chemically resistant to 15% Sodium Hypochlorite, 30% Sulfuric Acid, 30% Fluosilicic Acid, Ferric Chloride, Alum, and many others. Available in a wide stiffness range for both low and high-pressure applications.

Meets FDA criteria for food | Excellent chemical resistance

Alcohol general

Aluminum Sulfate (Alum)

Ammonium chloride

Ammonium hydroxide

Ammonium Sulfate (LAS)

Benzyl alcohol

Bleach

Brine solutions

Calcium Hydroxide 10% (Lime Slurry)

Calcium hypochlorite 20%

Citric Acid 50%

Ethylene glycol

Ferric chloride

Ferric nitrate

Ferric sulfate

Ferrous chloride – 43% in water

Ferrous sulfate

Fluosilicic Acid (up to 25%)

Formic acid

Glucose

Hydrochloric acid 33%

Hydrocyanic acid

Hydrogen peroxide

Hypochlorous acid

Iodine

Magnesium chloride

Magnesium sulfate

Phosphoric acid

Plating solutions

Polyaluminum Chloride (PAC)

Potassium hydroxide

Propylene glycol

Sodium hydroxide 50%

Sodium Bisulfite

Sodium Chlorite 12%

Sodium Hypochlorite 12.5%

Sodium sulfide

Sulfuric acid up to 30%

Tannic acid

Flex-A-Chem® – this tubing material consists of an outer Norprene jacket with an ultra smooth plasticizer-free bore inner liner virtually unaffected by acids, bases, salts, ketones, and alcohol. Available in a medium stiffness for applications up to 50 psi.

Meets FDA criteria for food | Superior chemical resistance

Ferrous Chloride (up to 40%)

Fluoboric Acid (up to 48%)

Fluosilicic Acid (up to 25%)

Hydrofluoric Acid (up to 48%)

Nitric Acid (up to 71%)

Phosphoric Acid (up to 85%)

Potassium Hypochlorite (up to 70%)

Potassium Permanganate (up to 6%)

Sodium Phosphate (up to 30%)

Sulfuric Acid (up to 98%)

Bases

Salts

Ketones

Alcohols

Isobutyl Alcohol

- Ink and solvent production

- Battery acid filling

- Specialty chemical production/processing

- Sensitive fluid transfer

Flex-A-Thane® – this polyurethane material can be used with various chemicals, including oil and liquid-based polymers, Sodium Hypochlorite, Alum, Ferric Chloride, fuels, and lubricants, among many others. Available in a medium stiffness for applications up to 65 psi.

Meets FDA criteria for food | Resistant to oils, greases and fuels

Cyclohexane

Diesel Fuel

Fatty acids

Gasoline

Heptane

Hexane

Kerosene

Lard

Mineral spirits

Soap solutions

Turpentine

- ASTM reference No. 1,2,3

- Castor

- Coconut

- Fuel

- Linseed

- Lubricating

- Mineral

Tube Material and Diameters

Blue-White® offers tubing in three different materials and various sizes, giving a wide range of application capabilities.

- The first letter in the tubing designation always indicates the tube’s material.

- The second letter indicates the tube size. Two of the same letters indicate a dual tube assembly.

- The letter “L” at the end of the code indicates a “low pressure” or “softer” version of the tube.

| Material Code | Tube Material | Tube Code | Tube Size | Tube Stiffness | A2 - PSI (bar) | A3 - PSI (bar) | A4 - PSI (bar) | °F (°C) |

|---|---|---|---|---|---|---|---|---|

| ND | Flex-A-Prene® | D | 0.075 | Medium | 125 (8.6) | 125 (8.6) | NA | 185 (85) |

| NEE | Flex-A-Prene® | EE | 0.093 | Medium | 110 (7.6) | 110 (7.6) | NA | 185 (85) |

| NGG | Flex-A-Prene® | GG | 0.187 | Medium | 110 (7.6) | 110 (7.6) | NA | 185 (85) |

| NHL | Flex-A-Prene® | HL | 0.25 | Medium | 65 (4.5) | 65 (4.5) | 65 (4.5) | 185 (85) |

| NHHL | Flex-A-Prene® | HHL | 0.25 | Medium | 65 (4.5) | 65 (4.5) | 65 (4.5) | 185 (85) |

| NJ | Flex-A-Prene® | J | 0.312 | Hard | NA | 125 (8.6) | 100 (6.9) | 185 (85) |

| NK | Flex-A-Prene® | K | 0.375 | Hard | NA | 125 (8.6) | 80 (5.5) | 185 (85) |

| NKL | Flex-A-Prene® | KL | 0.375 | Soft | NA | 30 (2.1) | 30 (2.1) | 185 (85) |

| NL | Flex-A-Prene® | L | 0.5 | Medium | NA | NA | 50 (3.4) | 185 (85) |

| NP | Flex-A-Prene® | P | 0.75 | Medium | NA | NA | 30 (2.1) | 185 (85) |

| TH | Flex-A-Thane® | H | 0.25 | Medium | 50 (3.4) | 50 (3.4) | 30 (2.1) | 130 (54) |

| TK | Flex-A-Chem® | K | 0.375 | Medium | NA | 50 (3.4) | 30 (2.1) | 130 (54) |

| GE | Flex-A-Thane® | E | 0.125 | Medium | 65 (4.5) | 65 (4.5) | NA | 130 (54) |

| GG | Flex-A-Thane® | G | 0.187 | Medium | 65 (4.5) | 65 (4.5) | NA | 130 (54) |

| GH | Flex-A-Thane® | H | 0.25 | Medium | NA | 65 (4.5) | 65 (4.5) | 130 (54) |

| GK | Flex-A-Thane® | K | 0.375 | Medium | NA | 65 (4.5) | 65 (4.5) | 130 (54) |

| G2G | Flex-A-Thane® | GG | 0.187 | Medium | 65 (4.5) | 65 (4.5) | NA | 130 (54) |

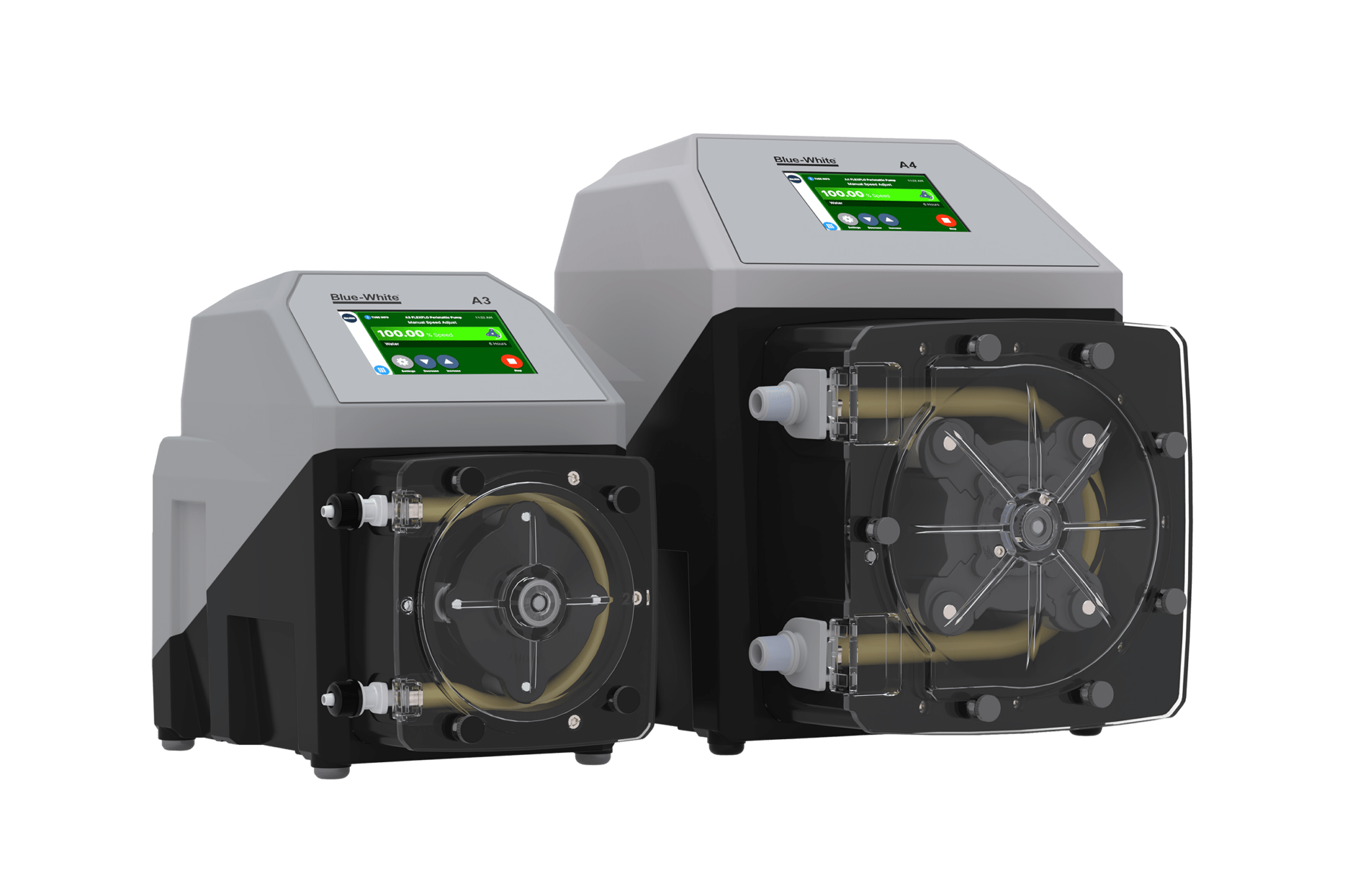

Featured Pumps

A2

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .02 - 17.2 | .07 - 65.1 |

| PSI | Bar |

| 125 | 8.6 |

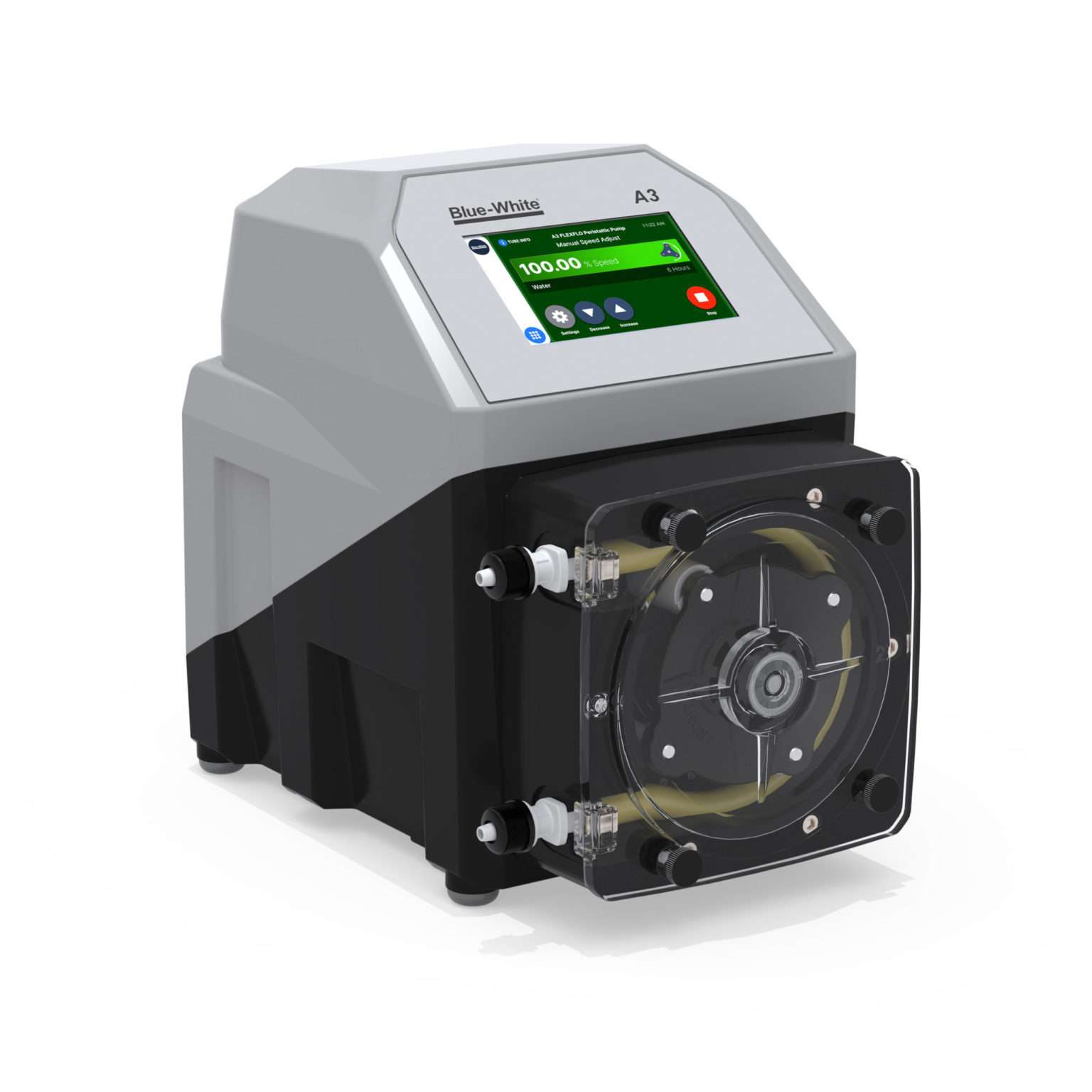

A3

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .001 - 33.3 | .003 - 126 |

| PSI | Bar |

| 125 | 8.6 |

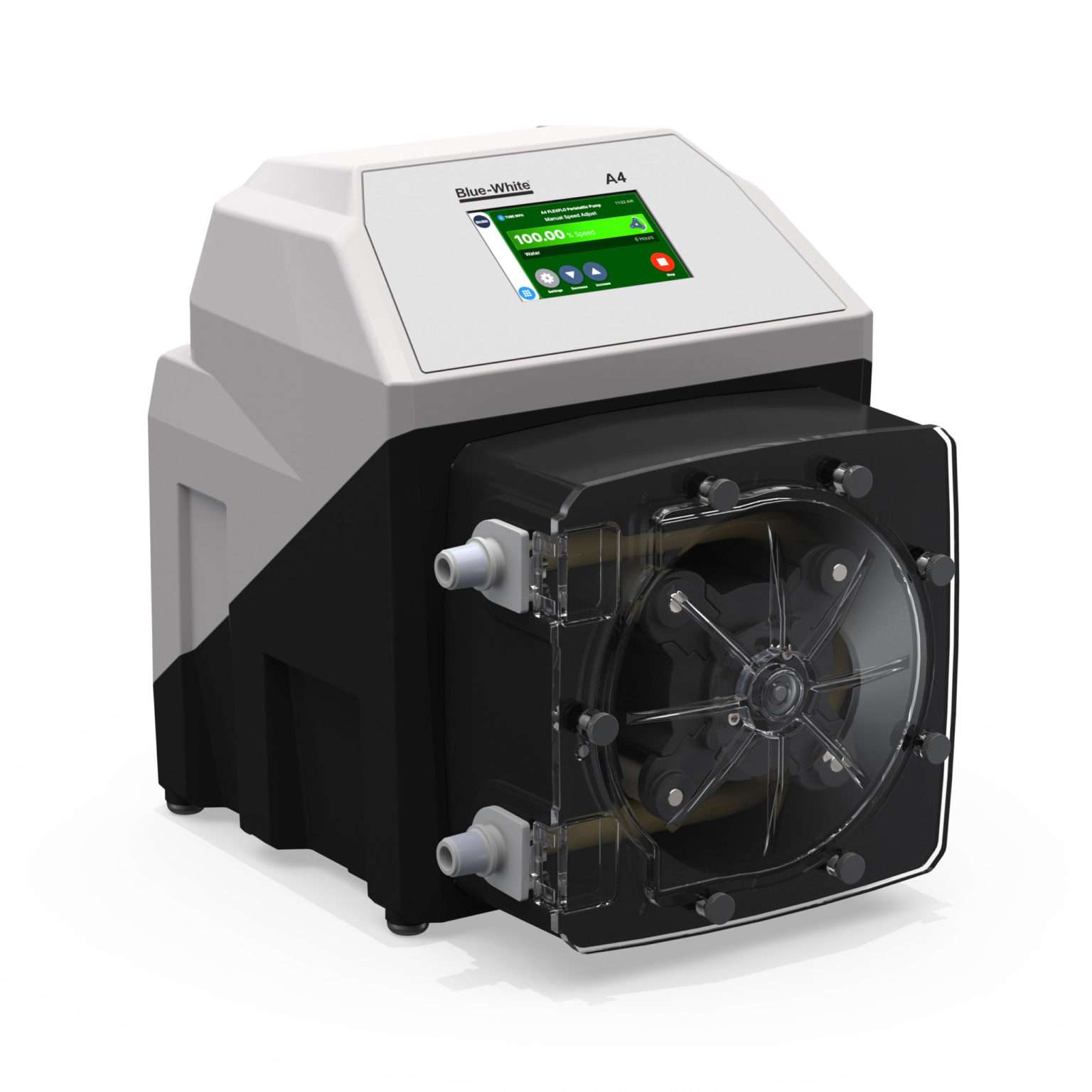

A4

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .01 - 158.5 | .04 - 600 |

| PSI | Bar |

| 125 | 8.6 |

M2

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .0085 - 17.2 | .032 - 65.1 |

| PSI | Bar |

| 125 | 8.6 |

M3

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .0002 - 33.3 | .0007 - 126 |

| PSI | Bar |

| 125 | 8.6 |

M4

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .0028 - 158.5 | .0108 - 600 |

| PSI | Bar |

| 125 | 8.6 |