Industrial

A4

Operation

Priming the Pump

Before priming the pump, or starting the pump, be sure that all suction and discharge lines are connected properly and that proper valves are open.

Prime mode can be accessed by pressing the App Drawer key. Then press the “Prime” key to enter Prime mode. In Prime mode, press the Start key. The pump will run at 100% speed for 60 seconds. The pump can be stopped at any time by pressing the Stop key.

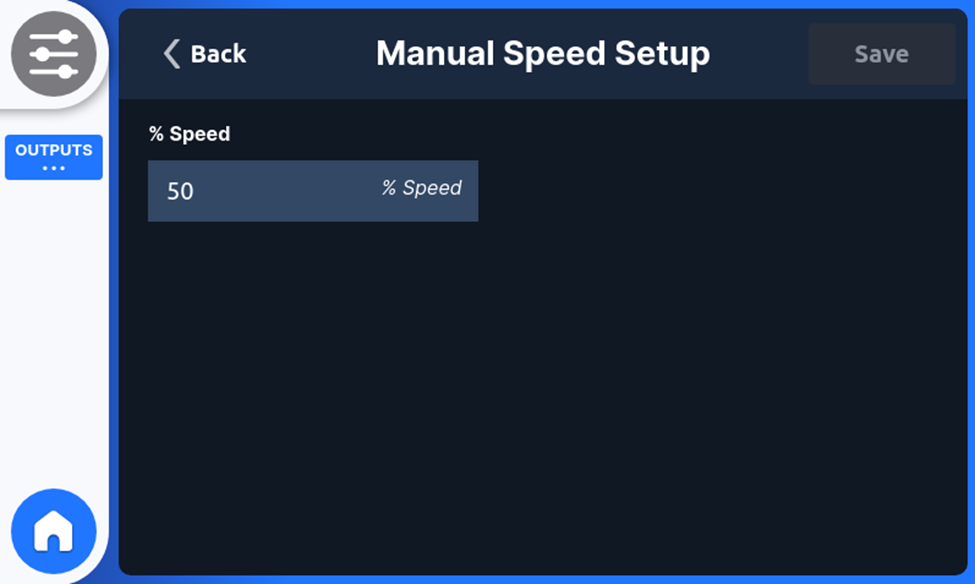

Manual Speed Adjust

The initial/default mode of the pump will be “Manual Speed Adjust.” Verify that you are in Manual Mode by noting the operating mode at the top of the touchscreen. Adjust pump speed by pressing the Up and Down arrow keys on the touchpad. Pump speed can also be adjusted by pressing the Settings key. Pump speed (flow rate, RPM) can be set to a specific value.

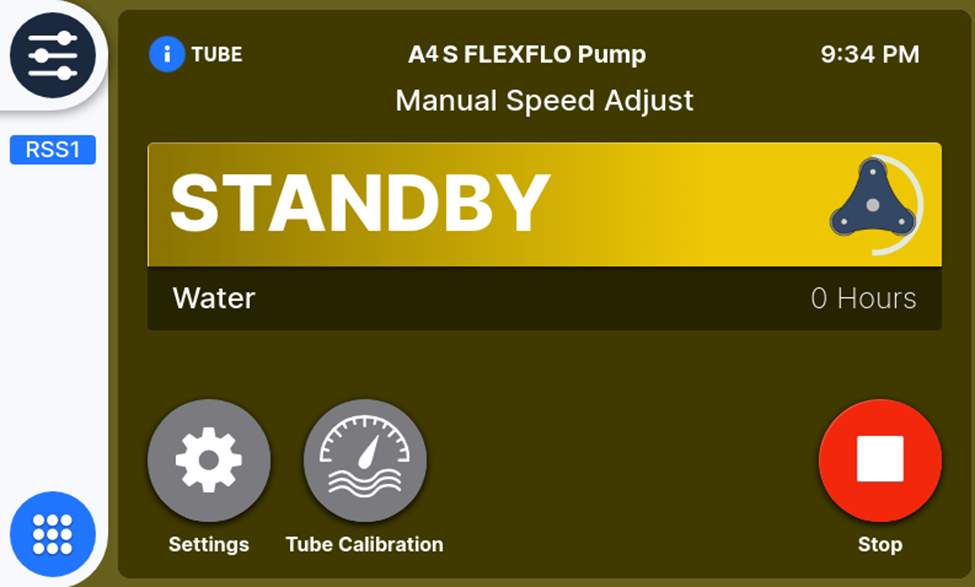

Remote Start/Stop

If using the pump in Remote Start/Stop Mode (indicated by “RSS1” on the left side of the touchscreen), press the Start/Stop key to put the pump in “Standby” state. The display will read “STANDBY” if waiting for a signal from the user-provided control system. Once a signal is received, the pump will start.

Other Operating Modes

To run the pump in other operating modes (4-20mA, Frequency, Pulse Input, Manual Cycle Adjust, Dispensing), press the App Drawer Key, and then press the desired operating mode key. Pump will go into desired run mode.

Calibration

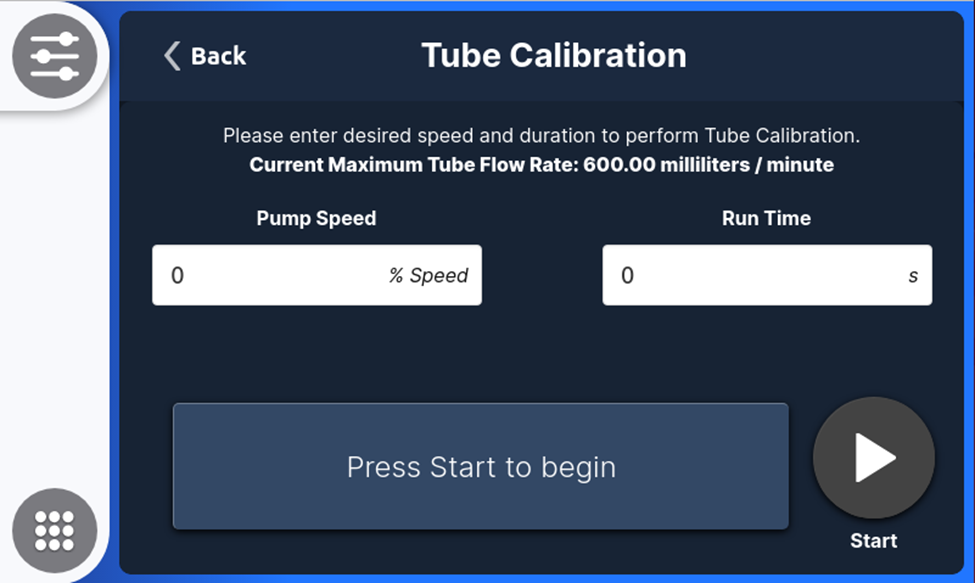

When in any of the operating modes, the pump can be calibrated by pressing the “Tube Calibration” key.

When in any of the operating modes, the pump can be calibrated by pressing the “Tube Calibration” key.

To ensure the most accurate pumping, a pump calibration is recommended prior to operating the pump. The A4S pump flow rate will vary depending on the suction line conditions. Calibrate the pump with actual suction line conditions.

To calibrate the pump:

- Connection tubing and open valves on the suction side of the pump to represent actual suction line conditions.

- Set up discharge and open discharge valves to dispense into calibration column/cylinder.

- Prime the pump, or run the pump in Manual Speed Adjust, pump so that the calibration column begins to fill. Stop the pump and note the solution level in the calibration column.

- Put the pump into Calibration mode by pressing the “Tube Calibration” key.

- Enter the desired calibration values for pump speed and run time in seconds.

- Press Start key.

- Pump will run for the time selected. Observe pump and calibration for proper filling. When the pump stops, measure the amount pumped by reading the calibration column level, noting the difference from starting position.

- Enter the amount pumped on the screen and press enter. The pump will calculate maximum tube flow rate automatically.

- The pump is now calibrated. Review calibrated Maximum Flow Rate by pressing Tube Calibration key.

Calibration results should be similar to the flow rating for the pump tube, but can vary depending on chemical composition, suction lift, viscosity, temperature, and other conditions.

When a new tube is installed in the pump, we recommend running a calibration after the pump tube has broken in after approximately 30 minutes.

Tube Failure Detection (TFD) and Tube Information

The A4S pump is equipped with leak-detection located inside the pump head. If a tube fails or leaks for any reason, the chemical will trigger the sensor, stop the pump, and activate an alarm.

If TFD alarm occurs, the pump will stop, close an alarm output, and the screen will flash with an red alarm. If the system has detected chemical, the pump tube must be replaced, and the pump head and roller must be thoroughly cleaned.

Remove the front cover to replace the tube and roller. Failure to clean the pump head properly will void warranty. See video on proper tube replacement.

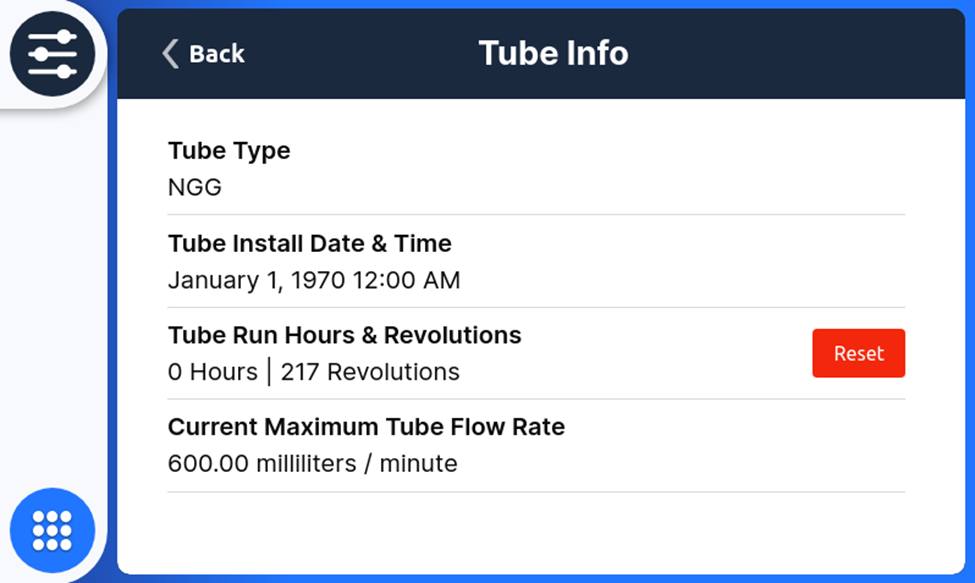

At any time, tube information can be accessed by pressing the Tube Info key.

At any time, tube information can be accessed by pressing the Tube Info key.

The Tube Information screen will show: Tube Type installed, Tube install date, Tube run hours & revolutions, and current Maximum tube flow rate.

FAQs

Frequently Asked Questions

A4S Operation

- Can a pressure switch be used with this pump?

Yes, a pressure switch can be used to open or close any number of electrical circuits of the pump. For one example, a pressure switch can be used to stop or start the pump by opening or closing the remote start/stop contact closure circuit protecting the pump from excessive pressure conditions.

What is a pressure switch?A pressure switch is a type of electrical switch that is designed to respond to changes in fluid pressure. It is commonly used in various applications to monitor and control the pressure of gases or liquids. When the pressure exceeds or falls below a predetermined set point, the switch activates or deactivates an electrical circuit, triggering the operation or shutdown of a connected device or system.

How do I increase pump output?For increased Max Feed Rate, there are a couple of options available. Firstly, replacing the pump tube and utilizing a compatible roller assembly that ensures proper alignment can lead to improved results. Additionally, another approach is to reduce the suction lift of the pump itself. This will also increase the out capacity of the pump. For more specific information and details, please get in touch with our customer service.

How do I trigger a dispense event? Can i remotely trigger the pump to dispense?The Dispense mode in the A4/A4S operates as a local mode, which does not respond to pulses for activation. Instead, it requires manual initiation by pressing the start button on the pump. On the other hand, the Pulse batch mode enables pulse acceptance and counting for batch dispensing. It allows the user to input a specific pulse count, and once that count is reached, the A4/A4S will dispense the predetermined amount of chemical programmed in the pump.

Can I stop the prime cycle before the 60 second time is up?Yes. Pressing the stop button will stop the prime cycle.

- Ask me a question!

Copyright © 2024 Blue-White

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Request a quote

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|