What’s in the Box

The C-1500N Pump is shipped with the following contents:

- C-1500N Diaphragm Metering Pump

- Discharge injection fitting with check valve

- Suction tube – clear PVC – 5′ length (3/8″ OD, 1/4″ ID)

- Flow Indicator

- Suction foot valve / strainer

- Suction ceramic weight

- Discharge tube – opaque polyethylene – 5′ length (3/8″ OD, 1/4″ ID)

- Wall Mount Bracket

- Instruction Manual

Preparation

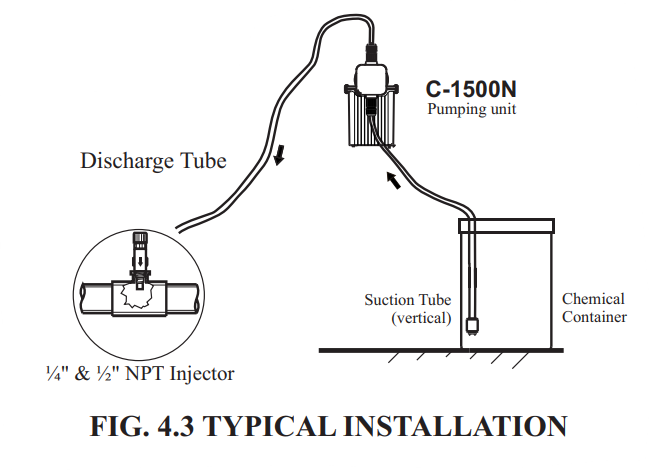

The C-1500N Pump is designed to be installed indoors or outdoors. The preferred installation is in a protected enclosure for maximum pump life. A cool, dry location where the unit can be easily monitored is recommended. Special ventilation is not required.

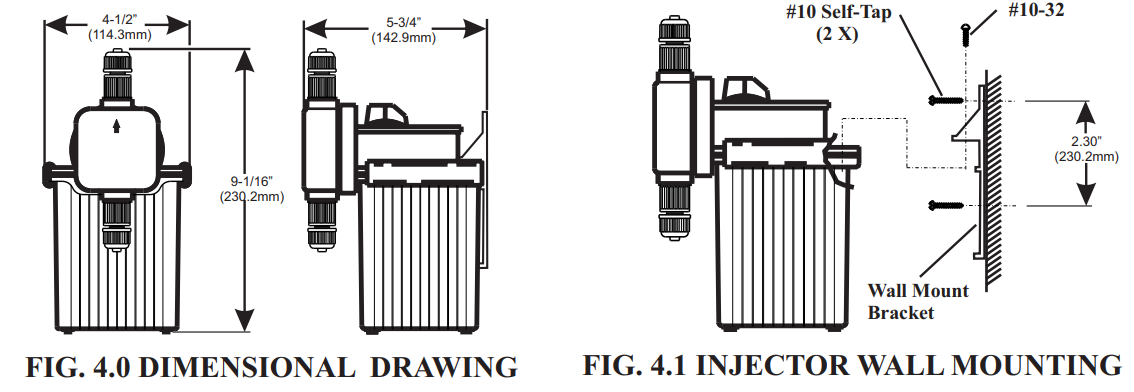

The pump can be mounted on a level surface or wall mount, where the pump head is vertical with suction at the bottom and discharge at the top.

Piping and physical installation

The C-1500N Pump must be level with discharge facing up to ensure pumping accuracy. Choose a location that minimizes suction lift.

If mounting the pump to the wall using the provided bracket, follow these instructions:

- Use the diagram and drawing on the manual (or below) to mount the bracket to a secure wall location. We recommend mounting the pump at a height where the adjustment dial is easily visible, and where it can be easily serviced.

- Ensure the pump is mounted level and screws are secure and will support the weight of the pump and any connected tubing.

- Pump can also be mounted to customer-provided bracket and structure. Be sure pump is mounted so it can easily be adjusted (via cam) and serviced.

Connecting Suction and Discharge Tubing/Piping

The C-1500N Pump comes with 1/4’” x 3/8” tubing connections.

Before connecting the tubing to the pump, be sure the pump is OFF. Wear protective clothing and eye protection when connecting tubing to chemicals or chemical lines.

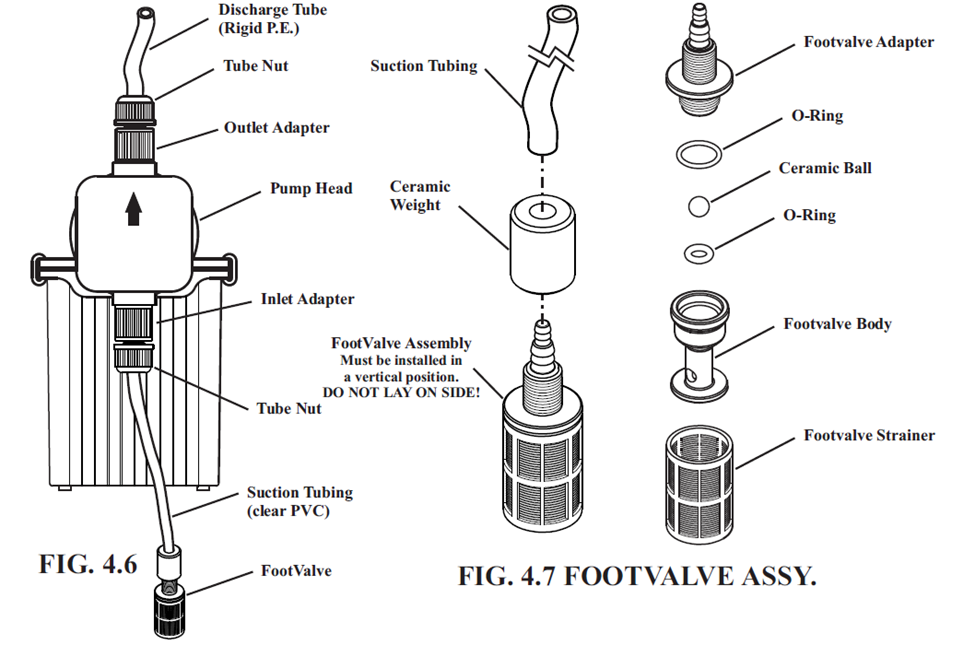

Connect the suction tubing (clear PVC -soft) to the pump using the provided tubes nuts, and place and secure the other end of suction tubing in the chemical tank/source. Using the provided foot valve/strainer and weight is recommended.

Connecting the Foot Valve. Trim the inlet end of the suction tubing so that the strainer will rest in a vertical position, approximately one inch from the bottom of the solution tank. This will prevent sediment from clogging the strainer. Loss of prime may occur if the foot valve is permitted to lay on the bottom of the solution tank in a horizontal position. Slip the ceramic weight over the end of the suction tube. Press the foot valve/strainer into the end of the tube. Secure the ceramic weight to the strainer. Drop the strainer into the solution tank.

Connect the discharge tubing (opaque PE – hard) to the pump using the provided tube nuts, and then connect the other end to the discharge point. If using the provided injection valve, be sure to mount it in an upward position to prevent air bubbles from collecting.

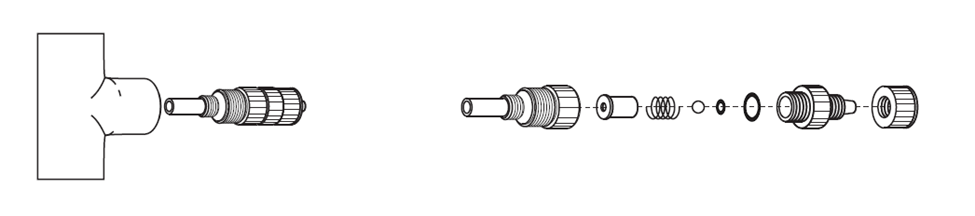

Connecting to the injector. Trim the end of the outlet tube leaving only enough slack to connect it to the Injection/Check valve Fitting (see below). Increasing the length of the outlet tube increases the back pressure at the pump head, particularly when pumping viscous fluids.

The Injection/Check valve fitting is designed to install directly into either 1/4” or 1/2” female pipe threads. Install the Injection/Check valve directly into the tee fitting. Do not install the fitting into a pipe stud and then into the tee.

The solution must inject directly into the flow stream. Use PTFE thread sealing tape on the pipe threads. Push the opaque outlet (discharge) tubing onto the compression barb of the Injection/Check valve fitting. Use the tube nut to secure the tube. Hand tighten only.

Injection/Check valve fitting fitting will require periodic cleaning, especially when injecting fluids that calcify such as sodium hypochlorite. These lime deposits and other build ups can clog the fitting increasing the back pressure and interfering with the check valve operation.

Wiring

Power Wiring

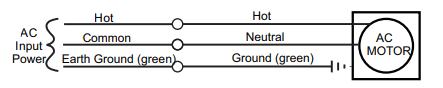

The C-1500N can be provided with a motor powered by 100 to 240VAC, 50/60Hz power. Pump can be provided with a wired power cord, or with a junction box.

Be certain to connect the pump to the proper supply voltage. Using the incorrect voltage will damage the pump and may result in injury. The voltage requirement is printed on the pump serial label.

Note: When in doubt regarding your electrical installation, contact a licensed electrician

See the below Wiring Chart for information and specifications in connecting to your electrical and control system.

Motor Lead Wires

| Input Voltage | Hot Lead wire | Neutral Lead wire | Ground Lead wire |

| 115V 60 Hz | Black or Yellow | Blue | Green |

| 220V 50 Hz | Blue or Yellow | Brown | Green |

| 230V 60 Hz | Black or Yellow | Red | Green |

| 240V 50 Hz | White or Yellow | Orange | Green |

| 24V 60 Hz | Blue | White | Green |

- Yellow lead wire = thermally protected motor, Black/Blue lead wired = standard impedance protected motor.

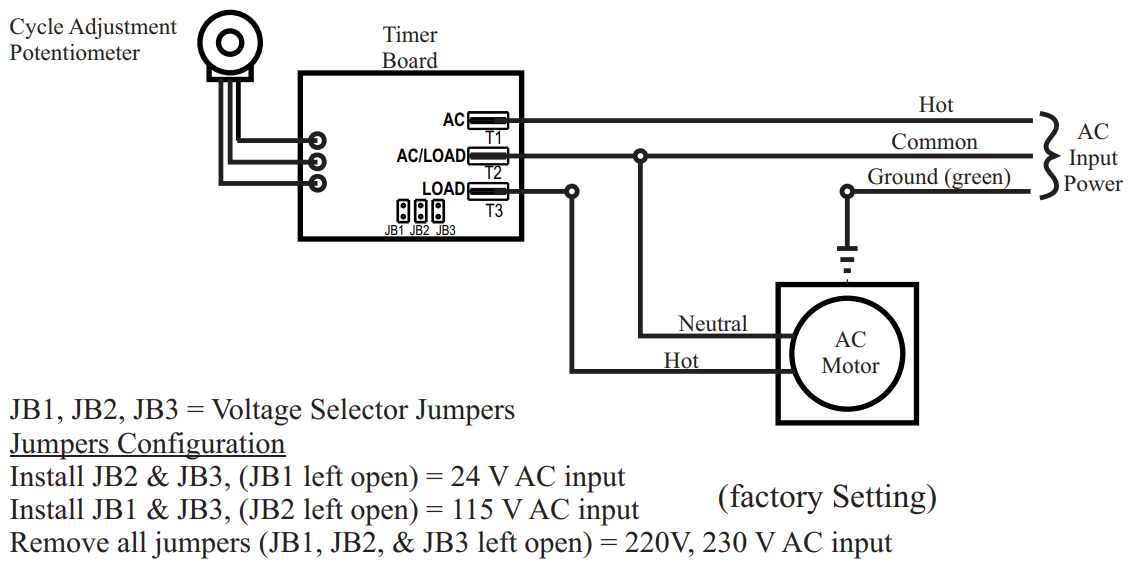

If you have a C-1500N with Cyle Time Board (no longer offered), then see below diagram for wiring instructions.

FAQs

Frequently Asked Questions

C-1500N Installation

- Can the pump be installed outdoors?

The C1500N pump housing carries a Nema 3R rating. "Intended for outdoor use primarily to provide a degree of protection against falling rain, sleet and external ice formation."

Will my pump operate w/o the flow indicator accessory included with this pomp?Yes, the pump can operate w/o the flow indicator. The flow indicator is a visual guide to determine the pump is operating. It can be replaced with clear suction tubing.

What accessories are included?Foot valve, 5 feet of suction tubing with flo indicator attached & 5 feet of delivery tubing, injection fitting and wall mount bracket .