General Maintenance

The CD3S pump requires very little maintenance. However, the pump and all accessories should be checked weekly to ensure proper pump performance. This is especially important when pumping chemicals that may be extra corrosive. Inspect all components for signs of unusual wear, clogging, leaking, swelling, cracking, discoloration, or corrosion. Ensure drive is moving freely and not exhibiting unusual wear or noise. Replace worn or damaged components immediately.

Cleaning Ball Checks, Strainer, and Injection Valves

If pumping a solution that has particulate or may contain particles or precipitate, checking and cleaning ball check cartridges, suction strainer, and injection valve periodically will be necessary.

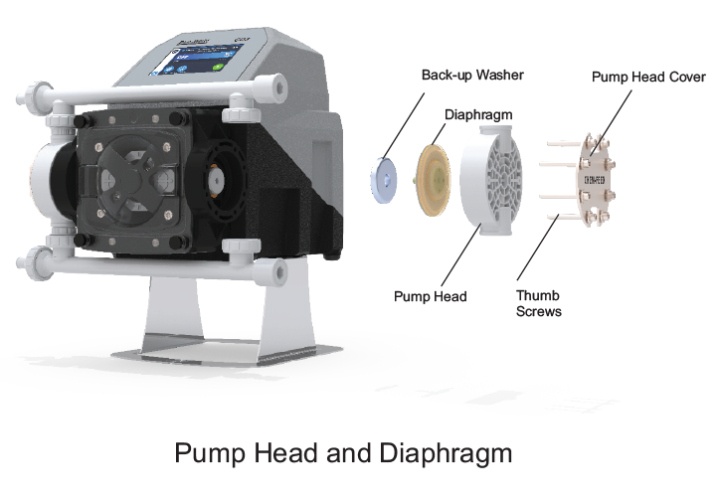

Replacing Diaphragms

The CD3S pump is equipped with a Diaphragm Failure Detection (DFD) that will sense a leak and stop the pump. This feature will prevent the pump from running when there is a leak.

When a leak occurs, or a diaphragm needs to be replaced, follow the below steps:

- Relieve system pressure. Disconnect the system plumbing from the pump tube adapters.

- Press the Stop key to stop the pump.

- Remove the pump head by loosening the allen screws.

- When changing the diaphragm, the pump head chamber and pump head cover should be wiped free of any dirt and debris. The pump stroke must be FORWARD when installing the diaphragm, and BACK when installing and tightening the pump head. Press the Start and Stops buttons to adjust the stroke position.

- When replacing the pump diaphragm, note the order of parts per the illustration below.

- Tighten pump head bolts in a star-shaped pattern, to not overtighten one side. Tighten bolts to 38 in-lbs. (Note: Check bolts and torque after 1-2 hours, as material may soften after the initial break-in period.)

Refer to the product manual for more information on pump maintenance and diaphragm replacement.