The use of chemicals is key in many aspects of drinking water and wastewater treatment, from disinfection to pH adjustment to coagulation and more (Figure 1). The chemicals used all have specific properties and can react differently to certain materials found in water treatment equipment, such as chemical metering pumps, and throughout the plant.

Chemical and material incompatibility can lead to increased maintenance and expense due to equipment damage or failure, as well as infrastructure damage. For well-established chemicals and materials, it may already be known which are compatible with which. But for infrequently used or proprietary products, it may not be so clear.

Why Compatibility Matters

As mentioned, when chemicals are not compatible with materials they come into contact with, it can cause a range of chemical reactions that may result in increased costs. This includes:

Corrosion. Caustic chemicals, such as chlorine, chloramine byproducts, ozone, and acids used in pH adjustment can corrode certain metals. This can cause contaminants to leech into the water, disrupting downstream processes or entering ratepayers’ taps. Over time it can also cause pipes to leak prematurely and valves to fail.

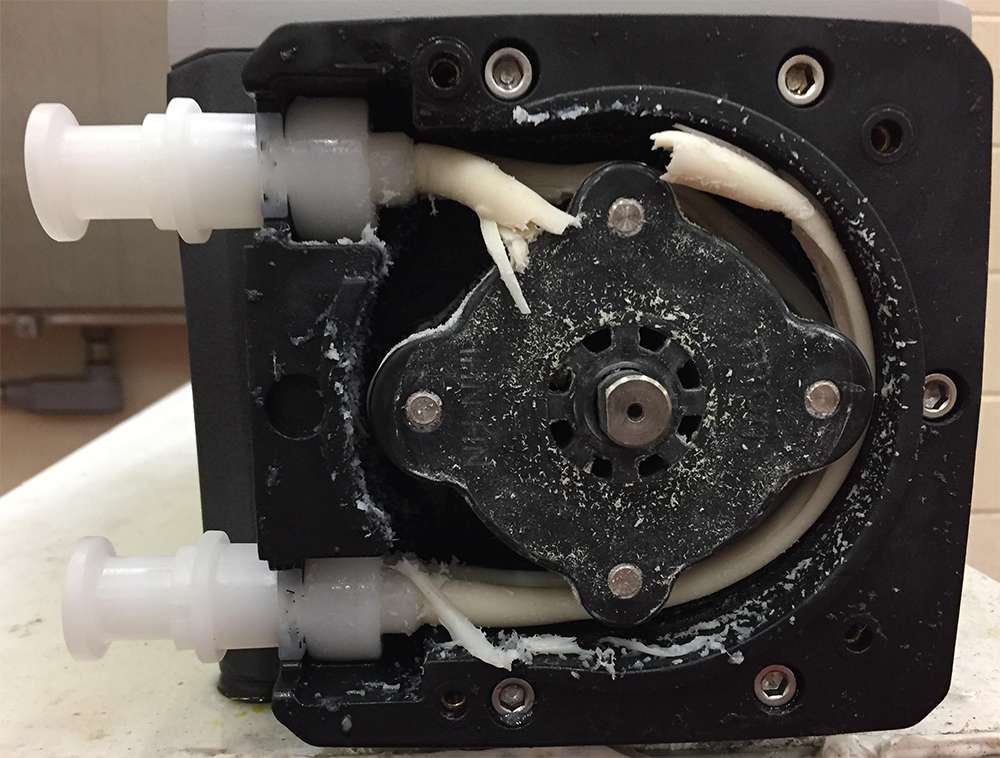

Degradation. Rubber, plastic, and other synthetic material can degrade and lose structural integrity when exposed to certain chemicals. This can cause leaks from pipes, gaskets, connectors, and more. In pumps, degradation of diaphragms and other components can reduce performance and require more frequent and costly maintenance and require premature part replacement (Figure 2).

Equipment damage. Poor chemical and material combinations can result in damage to a range of equipment, including mixers, meters, pumps, and more. Filter media may also be vulnerable to specific chemical types. Again, this will result in additional costs associated with maintenance, replacement, and downtime.

Health/safety risks. Because many of the chemicals in question are caustic, volatile, or otherwise highly reactive, there is a range of health and safety risks associated with their use. If equipment or piping begins to leak, or if machinery requires emergency maintenance, it can increase those risks by exposing personnel to these chemicals or to byproducts of their interaction.

How To Determine Compatibility

result, the tubing degraded, causing a chemical leak and potentially damaging the rotating mechanism.

For commonly used chemicals, operators may already know what materials are compatible and which are not. For example, liquid chlorine is safe to use with PVC, Viton, PVDF, and Hastelloy , among others, but will corrode types of galvanized steel, copper and copper alloys, rubbers and elastomers, and certain plastics. When considering use of any chemical the operator is unfamiliar with, some investigation is in order.

In some cases, manufacturers or suppliers may offer compatibility charts. These will list the types of materials found in a piece of equipment and the chemicals that are acceptable for use with the equipment. However, at other times this information may not be so readily available. When that is the case, it may be possible to at least get a list of the component materials. Once this is known, some research can be done to determine if the equipment will work with the chemical(s) in question.

Conversely, sometimes the unknown is the chemical itself. Proprietary chemicals, for example, may not have published compositions. The safety data sheet (SDS) could potentially offer answers, but not always. When all else fails, operators or project engineers can try to obtain samples of the material and chemical and perform their own in-house testing. If time does not allow for that, it may be worth considering a different combination.

Consider The Application

When discussing chemical compatibility, it’s important to understand that the application in question matters. For example, typically PVC can be used with sulfuric acid at low concentrations (ideally around 10% to 20%) and moderate to low temperatures. However, higher temperatures can soften PVC and make it more susceptible to acids and other caustic substances, even at typically low concentrations. Operators and project engineers need to consider these factors, as well as other chemicals that may come in contact with the primary chemical in question.

At the end of the day, it is important to balance all of these issues before choosing chemicals, equipment, and ancillary materials. In addition, project engineers should be mindful of both upfront and long-term costs. While it may initially save money to use a lower-cost pipe material, it could potentially cause increased costs in both material and labor if there are leaks or an outright equipment failure.

Whenever possible, it is worth partnering with equipment manufacturers who understand the importance of chemical compatibility and are willing to work together to find the right solution at the lowest possible cost. For example, Blue-White® Industries, located in Huntington Beach, California, has been manufacturing chemical feed pumps for 67 years. During that time they’ve seen many instances of the damage that can occur when chemicals and materials are not compatible.

For this reason, the company began publishing compatibility charts for its chemical metering pump components, as well as for their line of flow measurement equipment.

Blue-White also offers a variety of material options for pump components, as well as material test kits and a team of individuals to assist. All of these steps are designed to help ensure chemical compatibility within the system.

Written by:

Blue-White® Industries

714-893-8529