Chemical feed pumps are an essential component in ensuring the safety of water in public pools and other aquatics facilities, by dosing the optimum amount of chemical to achieve and maintain the correct water chemistry and comply with municipal health departments.

Sodium hypochlorite, chlorine, has long been the preferred sanitizer, while hydrochloric acid is commonly used to help balance the water’s pH.

It is not always a simple matter of getting the chemical from point “A” to point “B”. Problems can occur when there is a blockage in the system, such as clogged filter, or the system has stopped.

Hazardous conditions happen when metering pumps continue to dose chlorine and acid into a dead system, causing the off-gassing chemicals to mix. Chemical feed equipment is one of the biggest liabilities in a pool pump room and there are products to help reduce your liability for accidents happening in the pump room.

Chemical Metering into a Dead System

A controller is frequently sold with a pressure switch. The pressure switch should not allow chemical feed to be metered into a system where there is no flow of water. Often, pressure switches fail to recognize there is no flow of water and allow the pumps to keep dosing chlorine and acid into a system. This causes the off-gassing chemicals to combine in the plumbing or pump room, producing a dangerous reaction.

Solution to Keep the Pump Room Safe

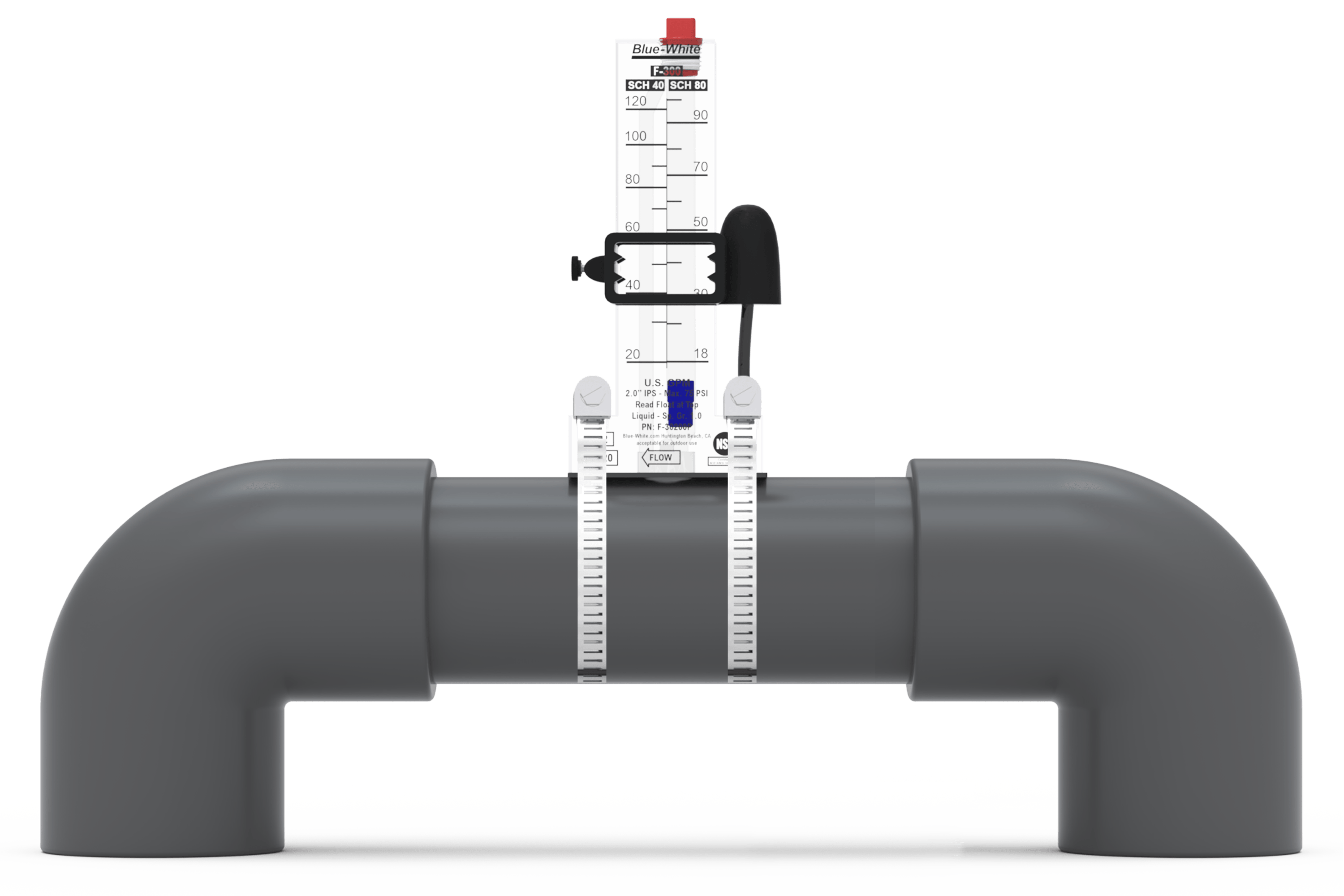

The F-300 acrylic flow meter with a switch/sensor will detect flow at a desired range and trigger an alarm when the flow is incorrect. When the flow meter float passes through the alarm trigger zone of the sensor, the built-in contact closure switch sends a signal to external devices. It can remotely turn on/off a chemical pump or other devices. It can also be used as an alarm signal to detect if the flow rate is not within the desired range.

The sensor/switch will detect both optimum and potentially dangerous situations:

- The recirculation pump is working properly.

- The recirculation system is at the desired flow rate.

- The chemical pump is injecting into a stopped system.

- There is a clog in the filter.

An F-300 flow meter with a flow switch/sensor will detect and monitor flow rate and is very easy to install and inexpensive to purchase. It will reduce downtime and keep pump rooms safe.

Written by:

Blue-White® Industries

714-893-8529