General Maintenance

The F-2000 Flowmeter requires minimal maintenance. During normal operation, there is no need for regular maintenance.

If the unit has not been in service for an extended period, it is recommended to inspect the fluid path by removing the sensor and cleaning the paddlewheel and axle.

Some conditions will cause increased wear on the paddle and/or possible damage to the unit. Damage caused by corrosive or abrasive fluids is not covered under warranty.

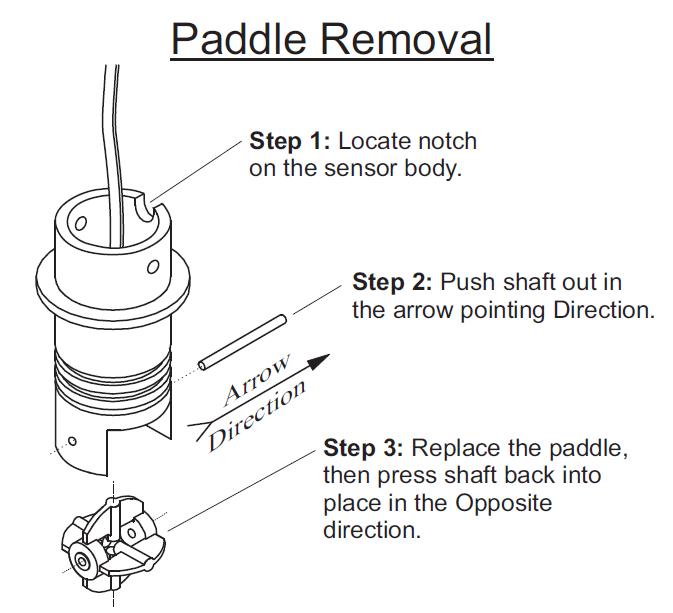

- Periodically remove the sensor assembly from the pipe fitting and inspect the meter for signs of wear and obstructions. Clean the paddle of any foreign objects. Paddle and axle wear can be caused by chemical attack and/or abrasive fluids. Replace the paddle and axle if worn.

- Although the meter is capable of operating at the high end of the flow range, the meter should not be allowed to operate continuously at flow rates in the upper 1/4 or 25% of the calibrated flow range. The paddle and axle life is directly related to the flow rate and the fluid being measured. Corrosive and abrasive fluids moving at high flow rates will cause increased wear, requiring frequent inspection and maintenance.

- Although the F-2000 is designed to withstand outdoor conditions, a cool, dry location where the unit can be easily serviced is recommended. The life of the LCD display will be severely reduced when installed in direct sunlight. Do not install the meter so that the LCD is in direct sunlight.

- O-rings should be inspected periodically. Immediately replace the o-rings at any sign of wear, swelling, cracking or discoloration.

- The meter is designed to withstand minor condensation inside the enclosure. Prolonged excessive moisture inside the enclosure, due to high humidity conditions, may damage the meter. Reduce the humidity or move the meter to a less humid location.

- RT Battery Operated Units: Replace the four AA batteries every 12 months. The program memory is “non-volatile” and will not erase when replacing the batteries. Processing power will be maintained for about 120 seconds while the batteries are being replaced. To replace the batteries, open the rear panel of the enclosure by removing the four Phillips screws. After replacing the batteries, be sure the foam insert is in place and the panel gasket seal is in good condition, before closing the rear panel.

- Test the electronics by removing the sensor assembly from the pipe fitting and spinning the paddle by hand. While spinning, the number “0” reading in the display window indicates that the battery is supplying power to the meter, but a signal is not being processed by the circuitry. In this case, the circuitry must be serviced by an authorized service center.

FAQs

Frequently Asked Questions

F-2000 Maintenance

- What are the common wear parts for the F-2000?

O-rings, paddle wheel, axle and batteries.

How long will the paddle and axle last?Although the meter is capable of operating at the high end of the flow range, the meter should not be allowed to operate continuously at flow rates in the upper 1/4 or 25% of the calibrated flow range. The paddle and axle life is directly related to the rate of flow and the fluid being measured. Corrosive and abrasive fluids moving at high flow rates will cause increased wear requiring frequent inspection and maintenance.

How long will the batteries last?Replace the two AAA batteries every 12 months. The program memory is “nonvolatile” and will not erase when replacing the batteries.