APPLICATION:

Chilled water systems provide cooling to a building’s air and equipment. They’re especially suited to situations where many rooms must be controlled individually.

Chilled water systems provide cooling to a building by using chilled water to absorb heat. The condenser water flows through the chiller and picks up heat, before being returned to the cooling tower. The cooling tower removes

heat from the condenser water by evaporating some of the condenser water into the atmosphere. The condenser water evaporates, heat is removed from the condenser water, and the cool condenser water then flows back to the chiller. The process is then repeated.

Problems can arise if the water being used is not treated ahead of the process. These problems may include scaling, corrosion and fouling.

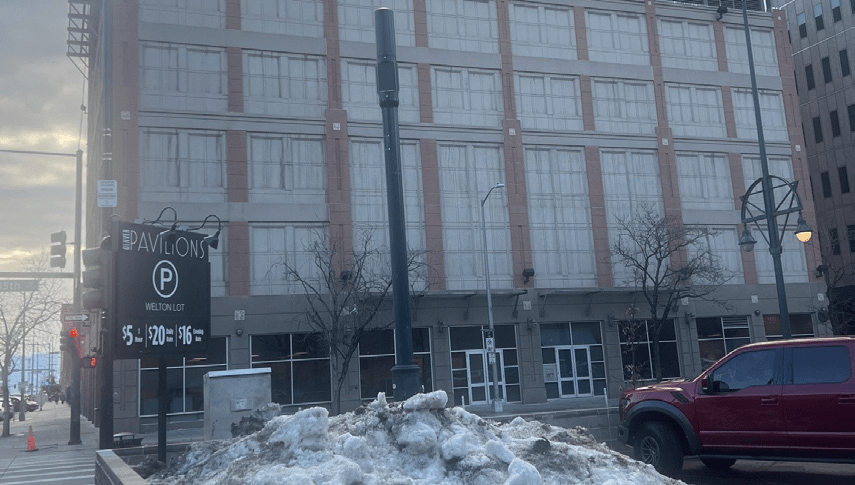

In this case, a regional utility company which owns and operates a chiller plant sells the chilled water to several facilities in the downtown area of their city. These facilities include hotels, city and county buildings, and residential high rises. The company sought a reliable chemical feed pump that would accurately dispense chemicals to properly treat scaling and corrosion issues.

PROBLEM:

The plant was using a single diaphragm pump to dose bleach and condenser water scale inhibitor to treat scale and corrosion. With the harsh chemical being used, the diaphragm pumps were having reliability issues, including diaphragm failure, loss of prime, and chemical leaks.

SOLUTION:

The utility company replaced several of the pumps in use with Blue- White’s CHEM-FEED CD1, a multi-diaphragm metering pump. The CD1 pump is equipped with Blue-White’s Exclusive Dual Diaphragm Hyper Drive Technology for smooth, near Continuous Feed – like a Peristaltic Pump but with no tube to change. The CD1 pump also features a built-in anti-degassing valve, ADV, that further reduces risk of vapor lock or loss of prime.

All CD1 pumps are outfitted with Blue-White’s exclusive DiaFlex® Diaphragms which are designed to last the life of the pump, eliminating the need to stock expensive rebuild kits.

RESULT:

The company’s Reliability Manager states that after switching to the Blue-White pumps he would describe the CD1 pumps as more “robust” than those used in the past. There has been a dramatic decrease in several issues previously experienced, such as repairs, priming, and leaks. Less repairs and rebuilds means less safety risks from chemical exposure and costs are reduced.

The company has determined to make the switch to the CD1 pump as their standard chemical feed pump.

Written by:

Blue-White® Industries

714-893-8529