Although there is more than one method of sanitizing water in aquatics facilities, chemical treatment is still a preferred choice for keeping water in commercial swimming pools, water parks, and water features clean and safe.

The most popular types of these reciprocating pumps are diaphragm and peristaltic. In this article, we’ll discuss one of the longest-standing and most popular methods for sanitizing water: Sodium Hypochlorite. Peristaltic metering pumps can automatically dose Sodium Hypochlorite and acids for pH control and are an excellent choice for ensuring the correct amount of chemical is delivered to the systems. This article will focus on peristaltic metering pumps delivering Sodium Hypochlorite.

Is Sodium Hypochlorite on Its Way Out?

In a word, no.

This has been a topic of discussion in the industry for many years. Although chlorine has pros and cons, it remains the disinfectant of choice in the aquatics industry. The reason is simple: it delivers dependable results, is familiar to pool technicians, and is inexpensive.

Alternative forms of disinfectants have difficulty matching the cost-to-benefit ratio of Sodium Hypochlorite.

Sodium Hypochlorite can be purchased from distributors, dealers, big-box stores, or even directly from some chemical companies. In certain regions, it may even be available for delivery on a regular chemical route.

The downside to Sodium Hypochlorite is that it can be heavy, and in some areas, it may be difficult to transport due to hazardous material regulations. In addition, Sodium Hypochlorite can lose its strength over time.

Still, Sodium Hypochlorite partnered with a dependable chemical metering pump has proven to be an effective combination for dependable water sanitation for decades.

Tips for Maximizing Your Peristaltic Metering Pump’s Performance

First, keep variables such as chlorine strength, type of chlorine, and feed rate to a minimum. If you keep chlorine strength consistent, then, as the swimmer load increases and the outside temperature rises, you simply increase the amount of chlorine to be dosed. Depending on the pumping unit, the pump may have built-in controls, or you may have an independent controller with which you make required adjustments.

A good quality metering pump is designed to be in service for years, and regular maintenance will significantly extend the unit’s life. It’s good practice to thoroughly inspect the pump every six months, check on the tube, and replace it if it shows signs of wear. Periodically lubricate the rollers. Rollers that are not rolling correctly can shorten the life of the pump tube.

Remember, when servicing chemical feed pumps, changing out chemical containers, or adding chemicals, safety first is always the rule. Wear the recommended protective gear, such as safety glasses and gloves.

Flow Indicator as a Diagnostic Tool

The flow indicator is a diagnostic tool installed on the suction tubing of your chlorinator. It allows you to determine whether the pump is working correctly. No indication means your chlorinator is not pumping. If the ball indicator bounces violently, it may indicate too much back pressure from a plugged injection fitting. The flow indicator is a simple way to monitor your system quickly and efficiently.

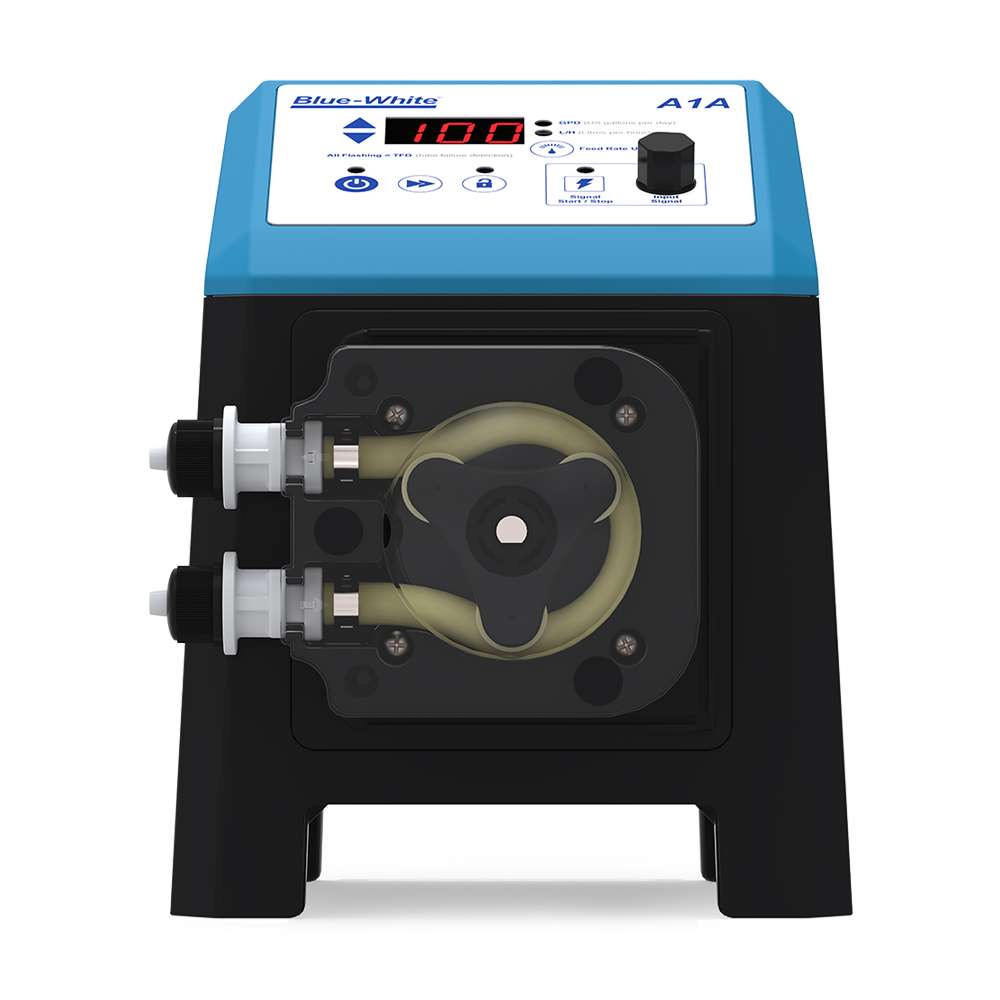

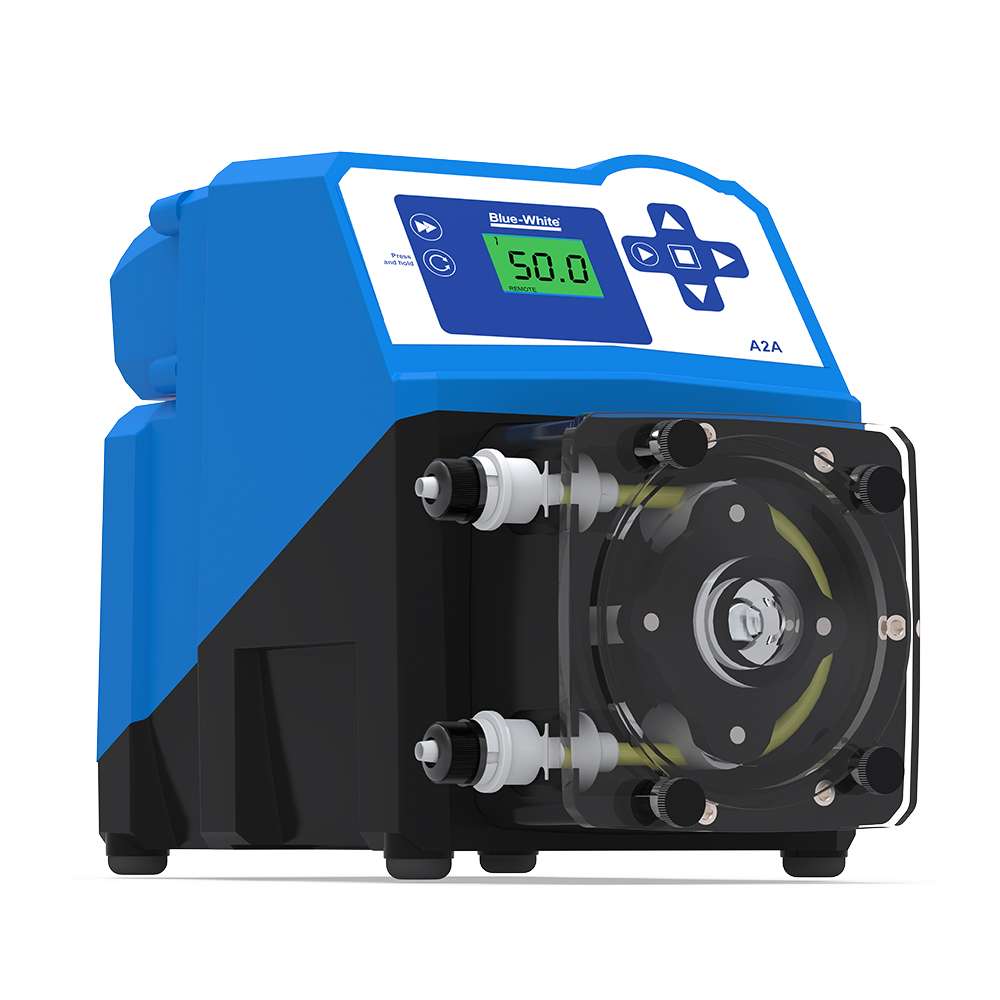

FLEXFLO® Peristaltic Metering Pump

Blue-White manufacturers FLEXFLO A1A and A2A Peristaltic Metering Pumps specifically for use in commercial aquatics, including public pools, resort facilities, water parks, and water features. These pumps are self-priming, will not vapor lock or lose prime, and do not have valves that can clog. These factors result in far less required maintenance, expense, and downtime.

A heavy-duty single-piece plastic rotor means no flexing and increased accuracy, with no metal springs or hinges to corrode. The machined squeeze rollers are optimum for accuracy and a prolonged tube life.

FLEXFLO A1A and A2A peristaltic metering pumps are often found in pump rooms where Sodium Hypochlorite, acid, and other chemicals are stored. The installation may also be outside where there is exposure to the elements.

For this reason, A1A and A2A metering pumps feature a NEMA 4X rated enclosure, which means they are corrosion-resistant, and protected from windblown dust, rain, splashing or hosedirected water. Protecting chemical feed pumps is critical in these often harsh pool equipment environments. The A1A and A2A’s energy-efficient variable-speed motors use the latest motor and drive technology, which saves energy dollars over the pump’s lifetime.

FLEXFLO’s safety features include a built-in Tube Failure Detection System (TFD) and a lockout feature. The TFD system detects a tube rupture, automatically shuts down the pump to prevent chemical spills, and warns the operator of trouble. The safety lockout feature prevents unwanted tampering.

Further Consultation

There are many factors to consider when choosing a chemical feed pump, including the size of the pool or water feature. How many gallons of water are being treated? What is the anticipated swimmer load? What’s the water temperature? What’s the air temperature? What’s the strength of the chemical being used? It pays to consult a pool industry professional to assist you in determining the optimum choices for your installation.

Written by:

Blue-White® Industries

714-893-8529