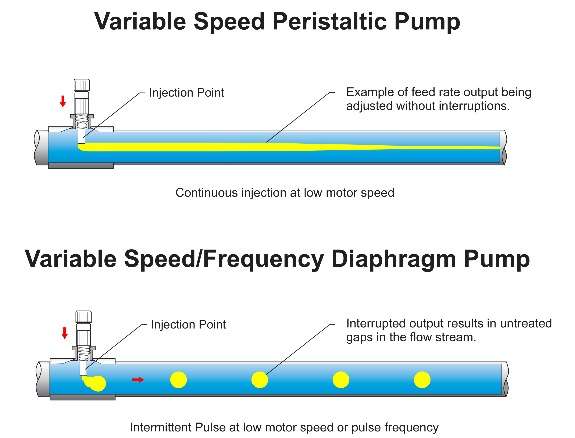

A peristaltic metering pump is a type of positive displacement pump. Fluid is pumped through a flexible tube in a peristaltic motion. Rollers are attached to a rotor which is controlled by a motor. As the rotor turns, the rollers pinch the tubing to force the fluid through. When the tube is not compressed, the fluid flow is brought into the tube.

Peristaltic metering pumps excel at pumping dirty fluids that contain particulate matter into lower pressure systems because they have no check valves to clog. The gentle forces created during the peristaltic pumping action will not damage delicate fluids within the tube.

In contrast, Diaphragm pumps have check valves on the suction and discharge side of the pump head. If either set of check valves becomes fouled, the pump will not dose precisely and loss of prime may occur. In addition, Diaphragm pumps can create shear stress on fluids, particularly if the pump employs a high velocity stroke action.

Peristaltic pumps are also extremely effective when pumping fluids that contain trapped gases. Fluids such as chlorine and hydrogen peroxide tend to release absorbed or occluded gases when subjected to a vacuum or changes in temperatures. Whereas a diaphragm pump will most often lose prime or vapor lock and fail when gasses build up in the pump head, peristaltic pumps are capable of pumping both fluid with particulates and those that off-gas without loss of prime or vapor lock.

Peristaltic pumps easily prime under maximum pressure but are usually limited to maximum discharge pressures of around 125 psi. In addition, they are capable of injecting into a vacuum without the need for metal spring loaded valves. Their output volume does not change due to changes in the system pressure.

Diaphragm pumps can operate at higher system pressures but require the addition of metal spring-loaded valves to resist siphoning. They are also more difficult to prime against pressure and their output will vary with system pressure changes.

Peristaltic in Use for Wastewater Treatment at a California Brewing Company

A popular brewing company located in San Diego, California has been using peristaltic pumps to assist with the purification of wastewater generated by its craft brewery. The brewery and the packaging hall generate about 100,000 gallons of wastewater per day. A chemical feed pump was needed that would not vapor lock due to the aggressive off-gassing chemicals being dosed.

They employ two peristaltic pumps to inject 12.5% sodium hypochlorite into the membrane bioreactor filter backwashes, a third pump injects 93% sulfuric acid prior to reverse osmosis, and an additional pump injects 12-14% sodium hydroxide to bring reclaimed water to a pH of 8 to prevent pipe corrosion. The FLEXFLO® Peristaltic Dosing Pumps they chose allowed the gas accumulation to be pumped through the tubing while also maintaining a smooth, accurate, and constant rate of flow with no potential for vapor lock.

Peristaltic Pumps at Work in a Florida Energy Company to Treat Reuse Water

An energy company located in Florida needed pumps to inject 12.5% sodium hypochlorite into reuse water to prevent biological build up within the water tubes of their condenser. Any build up within the condenser would greatly reduce efficiency to produce steam, hence less mechanical power.

The company chose a Blue-White CHEM-FEED Duplex Skid System equipped with two of Blue-White’s FLEXFLO® Peristaltic Chemical Dosing Pumps. The peristaltic pumps maintained their flow without losing prime.

When peristaltic pumps are in use the pump operator must be aware that constant squeezing of the tube degrades it over time, slowly diminishing the feed rate. Most manufacturers rate tubes in hours and the user must keep track of how many hours the pump has been running. When pump tubes are not regularly changed, or the injection point is not serviced, the pump tube may begin to leak.

Blue-White’s Exclusive, patented Flex-A-Prene® Multi-Tube Technology saves maintenance time and expense. These innovative pump head tubes provide optimal performance while operating at much higher pressures than conventional single tube designs. The Multi-Tube design delivers tube life up to four times longer than average single tubes.

FLEXFLO® Peristaltic Pumps are equipped with Blue-White’s exclusive patented, built-in Tube Failure Detection System (TFD). This technology detects a wide range of conductive chemicals with no false triggering. If the TFD detects tube failure, the pump will automatically shut off and energize a relay switch. This permits communication with external equipment, such as a back-up pump or alarm. It also serves to prevent chemical spills and added downtime.

FLEXFLO Pumps can be equipped with Blue-White’s Quick Disconnect Fittings. They are designed to help ensure operator safety by helping prevent chemical spills and splashing.

Quick Disconnects allow the operator to safely and quickly disconnect the metering pump. The RED outlet / discharge fitting has an automatic (active) functioning check valve, preventing chemical back flow. The NATURAL inlet / suction fitting functions as a check valve when tubing is detached, preventing loss of prime and spills while changing the tubing assembly. The valve is forced open when the tubing assembly is attached.

Other FLEXFLO® A3 features include; clamp-less over molded tube fittings; two CNC machined rollers and two alignment rollers for optimum squeeze and tube life. The maximum working pressure is up to 125PSI / 8.6 bar with a 2500:1 turndown ratio. Units are NEMA 4X / lP66 rate.

In conclusion, peristaltic metering pumps have been proven to be accurate, dependable, and tough in a multitude of commercial, industrial, and municipal chemical metering applications. They are an excellent choice when pumping fluids that contain particulates or trapped gas. The constant flow and gentle peristaltic pumping action help deliver precise amounts of chemical to a system without loss of prime.

Blue-White® is ISO 9001:2015 Certified.

Written by: Jean Hendrickson, Vice President in Charge of Advertising, Blue-White®

Download (PDF)