Fresh water is used in a broad range of process applications including boiler water and cooling system water treatment, as well as food and beverage process water treatment, among others. The resulting wastewater must then be properly treated before discharge into local sewer systems.

Many chemicals are utilized to aid in the remediation of wastewater. These chemicals may be used for the removal of solid particles, for pH adjustment, odor control, disinfection, foam prevention or removal, and sludge removal.

In this article we discuss the function of various types of chemicals used, and why we believe a FLEXFLO® peristaltic dosing pump is the best choice to deliver those chemicals.

Flocculant and Coagulation polymers are used to aid in the removal of solid particles. Flocculants separate solid content in the wastewater from the liquid content. A coagulant combines small particles to form larger chain particles. These polymers change the charge of the particles so that they will combine rather than repel other particles. The resulting long chain polymers will form a thick sludge and settle to the bottom.

To avoid common problems experienced with these materials, it is crucial to use a pump that will precisely and gently dose long chain polymers without causing damage to them. Additionally, polymer and flocculants are slippery, and spills can not only be very messy, but may also cause hazardous conditions for operators. Clean up is often difficult and costly.

To alert operators of leaks and to stop the pumping action, it is important to find a peristaltic metering pump that is equipped with a built-in tube failure detection system. The best tube failure protection systems will detect the presence of oil and water-based polymers in the pump head. Once the spill is detected, the pump should automatically shut down and possess the ability to energize a relay, thus permitting communication with external equipment such as a backup pump, an alarm, or a SCADA system.

Effluents present in wastewater must have a certain level of pH before they can be released or disposed of into a sewer network. The pH level is adjusted with the use of chemicals such as Sulfuric Acid, Hydrochloric Acid, or Phosphoric Acid, Sodium Hydroxide, and Calcium Hydroxide. An acid or base chemical is chosen depending on the pH level of the water.

It is critical in this instance to use a peristaltic metering pump with multiple features to combat the effects of the specific pH adjustment chemicals. First, the pump’s tubing should be chemically resistant to the specific acid or base being used. Second, the metering pump should be equipped with the previously mentioned tube failure detection technology, given that acids will attack the internals of the pump if left in contact. Therefore, it is imperative that if a pump develops a tubing leak, or worse, a rupture, the leak detection system will shut the pump down and alert the operator there is a problem. Once the offending chemical is cleaned from the pump head, and the tubing replaced, the pump should return to work.

In addition, it is important the metering pump have smooth, gentle, and continuous flow. This will prevent damage to the chemical being dosed, as well as prevent a gaseous build-up which can cause vapor lock and loss of prime.

Foaming in the activated sludge process will often develop in wastewater treatment processes. This foam floats and accumulates on the top of tanks. It can make measurements difficult to read and may overflow, causing an unsafe operating environment. Defoamers and antifoaming agents can be effectively dosed with a metering pump to minimize foam production and accumulation.

These foam inhibitors are either silicone compounds or high boiling alcohols. It is critical these foam inhibitors are precisely dosed, as dosing too much or too little can lead to further problems. Too little would result in ineffective treatment, and too much may worsen deposit problems and cause contamination.

Therefore, it is extremely important to choose a metering pump that doses a continuous and exact amount of chemical.

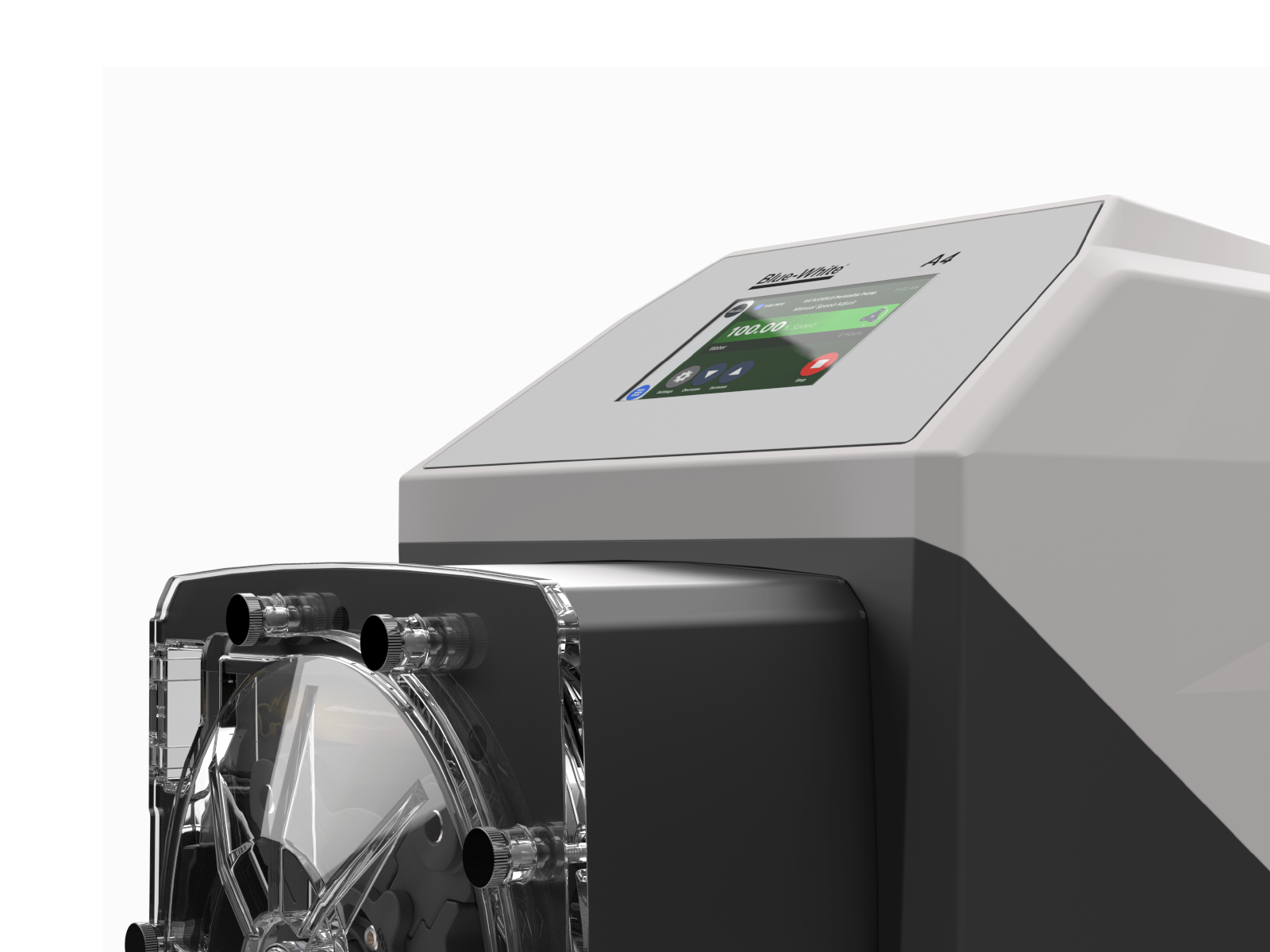

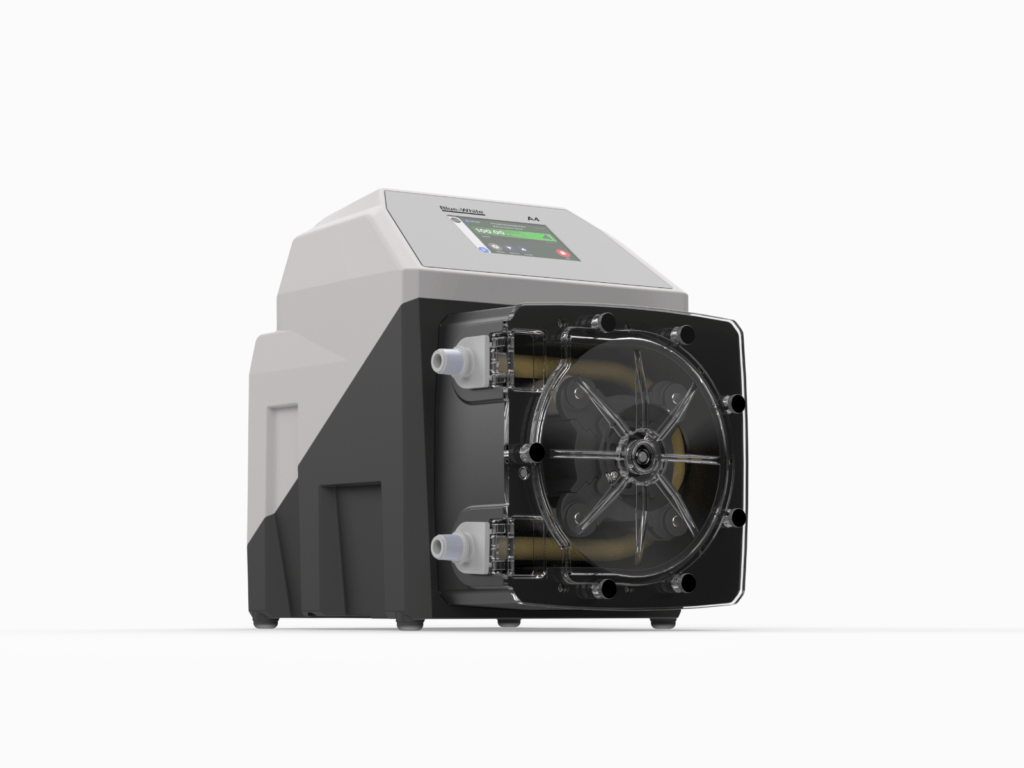

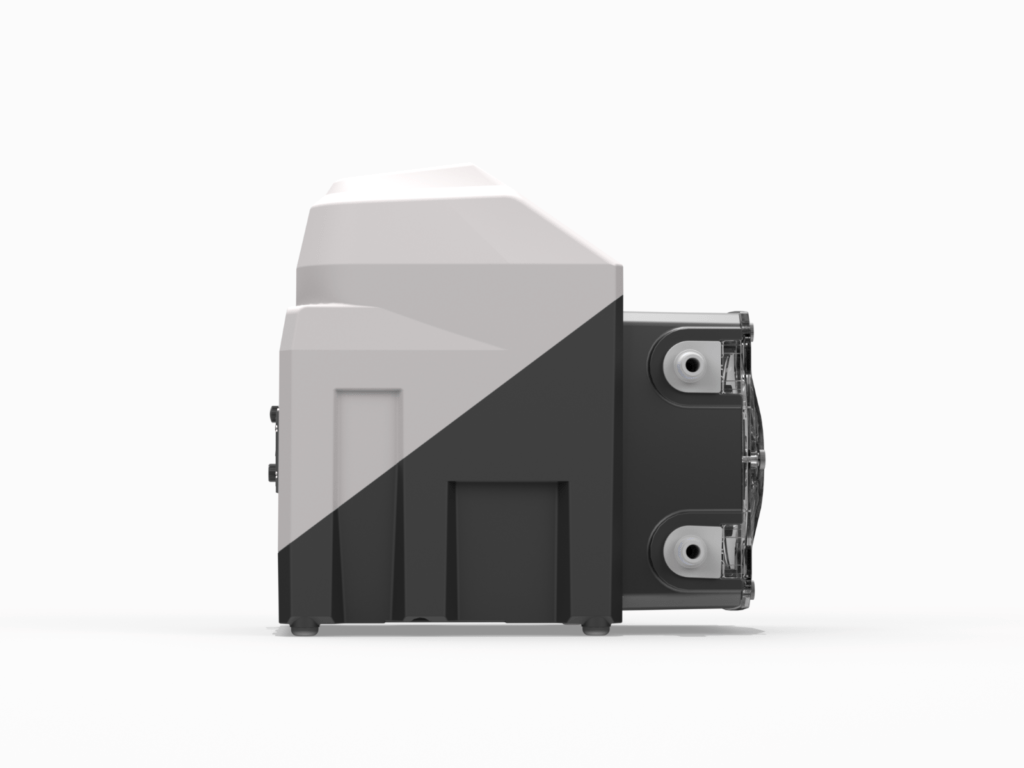

Blue-White’s FLEXFLO® A4 Peristaltic Metering Pump will precisely dose chemical for process water and discharged wastewater treatment. It not only delivers smooth, gentle feed that will not damage long chain polymers, but it will also accurately dose off gassing chemicals with no vapor lock and no loss of prime.

Operators will always know they are dosing the correct amount of chemical with the highly responsive and easy to read 5” touchscreen display. The LCD screen features easily recognizable icons, is highly intuitive and can be operated even while wearing work gloves. The A4 is equipped with the latest Communication Protocols and is designed to be fully upgradeable in the future.

The A4 may also be equipped with Blue-White’s Multi- Tube Technology. These innovative multi-tubes provide optimal performance while also experiencing higher pressure handling capabilities than conventional single tube designs. The Multi-Tube design also delivers service life up to four times longer than the average single tube design. These tubes are tough and available in number of materials to ensure the best possible chemical compatibility.

To save pump downtime and maintenance, each A4 peristaltic pump includes Blue-White’s exclusive built-in Tube Failure Detection System (TFD). The TFD detects a wide range of conductive chemicals with no false triggering. Should the TFD detect tube failure, the pump will automatically shut off and energize a relay switch. The relay switch permits communication with external equipment such, such as a back-up pump or alarm.

FLEXFLO A4V remote control signal options include Pulse, 4-20mA, Modbus TCP, EtherNet IP, and PROFIBUS for enhanced supervision and automation for critical metering and transfer applications.

When choosing a pump that will provide precise, dependable, and low-maintenance chemical delivery for the treatment of process water and discharge wastewater, consider the FLEXFLO® A4 peristaltic metering pump.

Written By:

Amparo Burke

Blue-White Industries

714-893-8529