Compatible Fluid Types

Acoustically conductive fluids

Particulate and bubbles with 50,000 ppm or less

Pre-Calibrated Chemical Profiles

- Water

- Aqueous Ammonia

- Ammonium Hydroxide

- Ferric Chloride 40%

- Sodium Bisulfite 40%

- Sodium Hypochlorite 12.5%

- Sodium Permanganate

- Hydrofluorosilicic Acid 25%

- Ammonium Sulfate 10%

Additional approved chemicals (customer digital calibration required.)

- Alum (Aluminum Sulfate 48%)

- Ferric Chloride 50%

Non-working chemicals

- Sodium Hydroxide

- Peroxide

- Neat polymers

Materials of Construction

Inline Pipe Fitting/Transducer:

Transducer: PEEK – See chemical resistance

Pipe Fitting: PVDF (optional PVC) – See chemical resistance

Enclosure: NEMA 4X (IP66) Polycarbonate.

Sizes and Flow Rates

Range 1: 10 – 5,000 mL/min (0.158 – 79.2 GPH), Range 2: 100 – 10,000 mL/min (1.58 – 158.5 GPH).

Units of measure: Configurable for US Gallons, Liters, or milliliters. And time units of seconds, minutes, hours, and days.

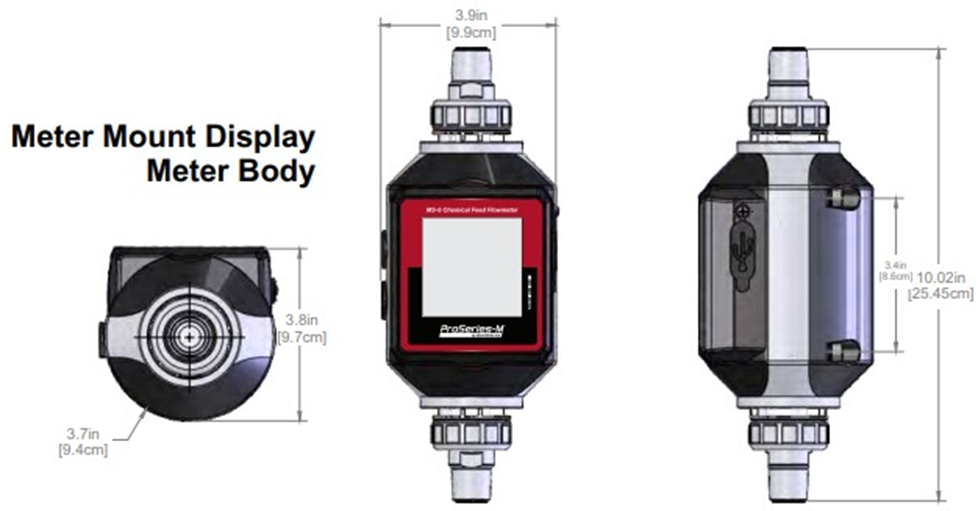

Dimensions

Weight: 1.5 lb. (.68kg)

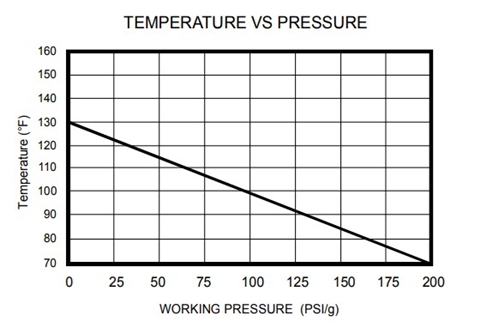

Temperature and Pressure Ratings

Operating Temperature: 14 °F to 104 °F (-10 °C to 40 °C)

Max pressure: 200 PSI

Electrical and Controls

Electrical Power Requirements: 5VDC (5 watts max.)

MS6 ships with power supply cord kit which includes:

- U.S. Transformer, 115VAC 60HZ / 5VDC, NEMA 5/15 plug

- Europe Transformer, 230VAC 50HZ / 5VDC, CEE 7/V11 plug

- Australia / New Zealand Transformer, 240VAC 50HZ / 5VDC, AS 3112 plug

- U.K. Transformer, 230VAC 50Z / 5VDC, BS 1363/A plug

Input and configuration: All configuration and input programming is done through the Blue-Central software. Blue-Central Software is downloadable from the Blue-White website and is compatible with Windows 7, 8, 10, 11 or Mac (OSX 10.11/10.12/10.13). Connector to the MS6 is via USB-C to USB-A cable.(included.)

Outputs:

- Isolated 4-20 mA output – fully configurable

- 0-10000 Hz Pulse output – fully configurable

One Solid State Relay, Load capacity: 24V, 100mA max (ext. supplied)

- Configure to flow rate for high/low/range rate trigger. Programmable release values enable auto release or manual latching operation.

- Configure to flow total for automatically triggered, timed batch operations for proportional feed applications.

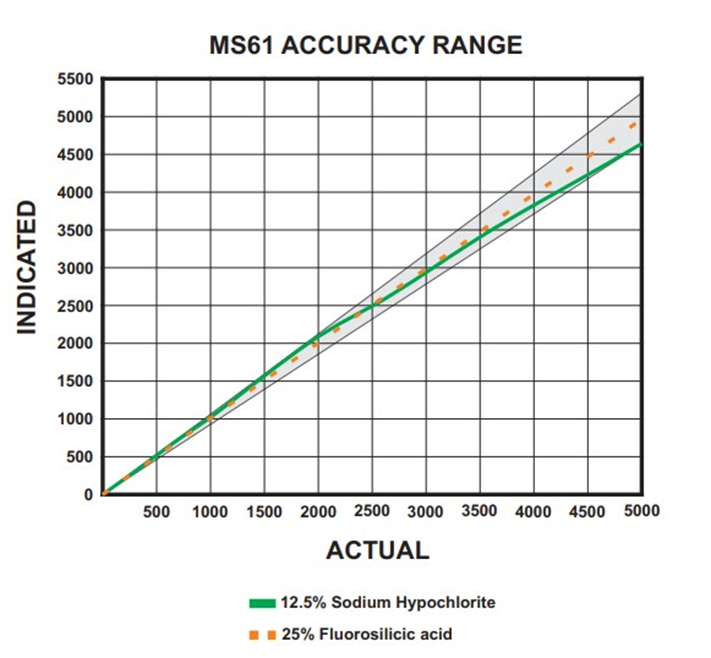

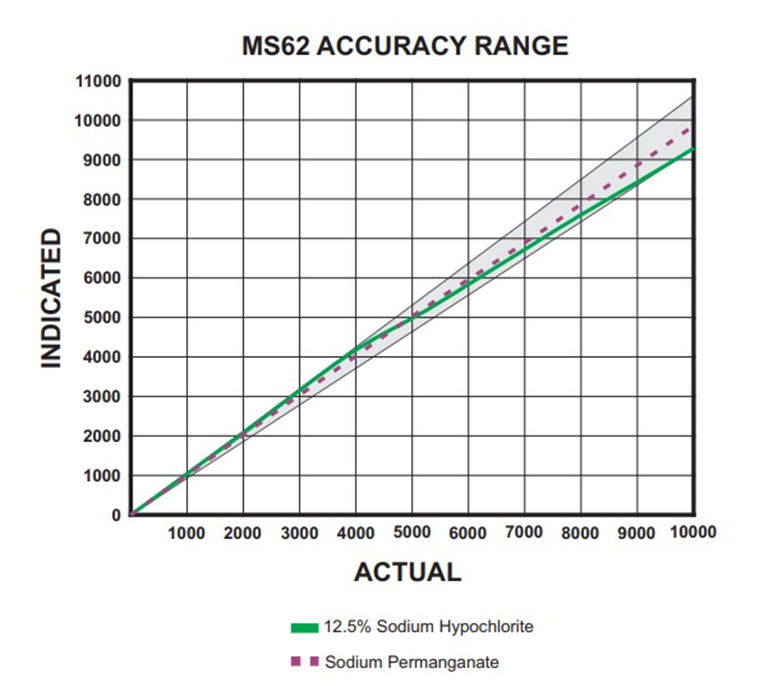

Accuracy

MS6 accuracy with pre-configured chemicals is +/- 5 of flow reading. Accuracy other chemicals that have had a customer chemical calibration are +/- 5% of flow reading (flow reading must be within +/- 50% of calibrated flow.)

Agency Listings

This meter is certified to NSF/ANSI Standard 61 – Drinking Water System Components – Health Effects

CE – complies to the IEC 61000-6-1 and 6-3, IEC 61000-3-2 and 3-3

FAQs

Frequently Asked Questions

MS6 Specifications

- Are there any chemicals that will not work with MS6?

Yes. There are chemicals that will not work with the MS6, specifically sodium hydroxide, sulfuric acid, and neat polymers. Chemicals must be acoustically conductive and contain particulate less than 50,000 ppm.

Is caustic soda compatible with the MS6?No. The MS6 will not work with caustic soda - NaOH - Sodium Hydroxide.

Is the MS6 rated NEMA 4X?Yes. The MS6 flow meter enclosure is rated NEMA 4X, and has IP66 rating.

Is the MS6 rated NSF 61?Yes. The MS6 flow meter is NSF 61 Listed.

What is the maximum flow the MS6 can read?The MS61 model can read flows as high as 5,000 ml/min (79.2 gph). The MS62 model can read flows as high as 10,000 ml//min (158.5 gph)

What is the minimum flow the MS6 can read?The MS61 model can read flows as low as 10 ml/min (.158 gph). The MS62 model can read flows as low as 100 ml//min (1.58 gph)

How do I find out if my chemical will work with the MS6?The MS6 Flowmeter has been tested with a number of chemicals, some of which are listed on the Datasheet. For other chemicals, we recommend contacting the factory with SDS sheet and process information. We will be able to advise on compatibility based on previous feedback or chemical make-up. An option to buy and trail a unit may be available.

If my chemical has bubbles, can it be used on the MS6?The MS6 meter can measure chemicals with bubbles and particles provided the bubbles and particles are not so large, or numerous, as to block the ultra-sonic sound beam. For example, the MS6 functions very well measuring sodium hypochlorite. The MS6 meter takes many measurements per second, so while small bubbles and particles can reduce the number and quality of the measurements, the meter is still able to take enough measurements for an accurate reading. Installing a strainer/filter directly before the MS6 can break up large bubbles and filter out particles.

What chemicals can, and can’t be used with the MS6?The sensor will work with acoustically conductive fluids with particulate and bubbles 50,000 ppm or less. A list of Pre-Configured (factory-tested) chemicals is available in the product datasheet, and includes:

- Water

- Aqueous Ammonia 10%

- Ammonium Hydroxide 30%

- Ferric Chloride 40%

- Sodium Bisulfite 40%

- Sodium Hypochlorite 12.5%

- Sodium Permanganate 40%

- Hydrofluorosilicic Acid 25%

- Ammonium Sulfate 10%

Additional approved (non factory tested) chemicals are:

- Alum

- Ferric Chloride

- Chemicals that can’t be used:

- Sodium Hydroxide

- Sulfuric Acid

- Neat polymers

Why is the accuracy different for different chemicals?Different chemicals have different accuracies in an ultrasonic meter because they have different acoustic properties. Acoustic properties are the physical properties of a material that affect the way sound waves propagate through it. Some of the most important acoustic properties for ultrasonic flowmeters are the speed of sound, the attenuation coefficient, and the density. The speed of sound in a fluid is the distance that a sound wave travels in a unit of time. The speed of sound is affected by the temperature and pressure of the fluid, as well as the composition of the fluid. The attenuation coefficient is a measure of how much sound energy is lost as it travels through a fluid. The attenuation coefficient is affected by the composition of the fluid, as well as the frequency of the sound wave. The density of a fluid is the mass per unit volume. The density of a fluid affects the way sound waves propagate through it.

How repeatable are the measurements over time?We do not have exact data at this time but Ultrasonic flowmeters are generally very repeatable. The repeatability of an ultrasonic flowmeter is affected by a number of factors that include the type of fluid being measured and the installation conditions.

What is a “wetted fitting”?A component of a metering pump or flowmeter that comes in contact with the fluid being pumped or measured is considered a WETTED FITTING or WET COMPONENT. Examples include O-ring seals, gaskets, inlet and outlet fittings, diaphragms, valve components, etc.

What is a “true union”?The term TRUE UNION is used to define a flowmeter with double unions, on the inlet and outlet side of the flowmeter, that allow for servicing of the flowmeter, whether you are cleaning, repairing, or replacing the flowmeter. The main portion or “body” of the flowmeter can be taken out of line for ease of service without disassembling the entire system.

Why does the working pressure rating go down when the fluid temperature goes up?The properties of the materials used in the flowmeter can contribute to pressure changes with temperature. For example, certain materials used for seals, gaskets, or O-rings may experience thermal expansion or exhibit decreased elasticity at higher temperatures. This can result in leaks or reduced sealing effectiveness, leading to pressure loss.

What is NEMA 4X?NEMA 4X is a rating for enclosures that indicates they are designed to provide protection against corrosion, windblown dust and rain, splashing water, and hose-directed water.

Click here for more information.