Visit BW® at Aquatech Amsterdam for Expert Chemical Dosing Solutions

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

New innovations in pump engineering are simplifying the setup and operation of metering pumps, making them userfriendly, versatile, and upgradeable.

A metering pump serves a simple but important role in any water treatment system. In theory, these pumps should be relatively simple to set up and run. In reality, some can be quite complicated. Operators must often pour through a 60 to 120 page manual, then navigate awkward interfaces and decipher prompts. It can take hours to get the system ready, and if there is a mistake during setup, it can cause additional frustration, and often costly delays.

Innovation in pump engineering is changing this. Taking cues from smartphones, new technology is simplifying the setup and operation of metering pumps, making them userfriendly, versatile, and even upgradeable.

Even before a metering pump is purchased, it can begin consuming manhours, as the potential user must first specify and select the pump best suited for the application. It isn’t simply a matter of determining speed, pressure and feed rates. Communication protocols, maintenance requirements, and ease of operation must also be considered.

Some innovative metering pumps are doing away with this lengthy selection process by offering all-in-one solutions (Figure 1). These pumps can be run at various speeds and pressures and will accommodate a wide range of feed rates. In addition, these Chemical Feed Pumps are engineered with the most preferred communications built in: 4-20mA input/ output, Remote Start/ Stop, Pulse Input, Alarm Outputs, EtherNet/IP, Modbus TCP/ IP, PROFIBUS. The only thing that must be selected is the pump tube material.

Because the manufacturer builds as much functionality into the pump as possible, plant personnel spend less time determining specifications and selecting options.

The beauty of a peristaltic pump is that once it’s up and running, it should be able to operate continuously with little operator intervention. With some older technologies, that can be quite a chore. The latest technologies, however, consider the user experience from the very beginning.

For example, when a FLEXFLO® M3 peristaltic pump is powered on for the first time, a welcome screen appears that walks the operator through the setup process step by step. It will ask the operator questions, such as what tube is being used, what chemical is being metered, the time, etc. This allows the pump to be operationally ready in a matter of minutes, without any need to thumb through a manual.

The FLEXFLO M3 interface is modeled after modern smartphones. It utilizes a touchscreen with an app drawer and easily recognizable icons. Attention has been paid to even the most minor details to create a pump that is simple to use. These details include a “Home” button, which can save time and frustration by making it easier to jump between apps and features. There’s also a “Name” feature, which allows operators to display a custom ID name, for example, HYPO1 on the main screen of the pump could alert it’s one of two pumps running sodium hypochlorite.

Figure 2. Seemingly simple features, such as a

The “Home” button and app-based interface can

make metering pumps easier to use.

As pump technologies become more advanced, they also become more dependent on their software to perform well. But unlike a smartphone or computer, a metering pump is not always easy to update. If there is a patch, or a security update that must be downloaded, the pump may need to be taken offline and brought to a service center, resulting in downtime and expense.

To avoid this hassle, many newer pumps, including FLEXFLO M Series, are being designed with built-in USB ports. These allow operators to download software updates directly from an internet-enabled laptop and upload to the pump.

This feature assists water treatment facilities in several ways:

One of the main values of peristaltic metering pumps is that, for the most part, operators set them up and let them run with minimal maintenance requirements. But nothing runs perfectly forever, and the most advanced metering pumps offer a variety of features that can help avoid problems, or warn operators when one occurs.

For example, Blue-White’s FLEXFLO peristaltic pumps have patented built-in tube failure detection (TFD) (U.S. Patent Numbers 7,001,153 and 7,284,964). The TFD System will detect a wide range of conductive chemicals present in the pump head, most often caused by tube failure. If this should occur, the pump will automatically shut off and energize a relay switch, permitting communication with external equipment, such as a backup pump or alarm. The pump will not restart until the problem has been resolved. This action can help eliminate costly chemical spills and Labor intense clean-up. Condensation and wash-down procedures will not cause false triggering. TFD is simple, efficient, and built-in.

If operators desire an ounce of prevention, they can utilize a revolution timer. Suppose a pump tube is estimated to fail after 1 million revolutions (meaning the tube is compressed and decompressed 1 million times), the revolution timer can be set for between 500,000 and 800,000 revolutions. Once the pump has completed the set number of revolutions, an alert is sent, and an operator can change the hose before it fails.

SD1 Western Regional Wastewater Treatment Plant is located on the Ohio River in heavily industrialized Northern Kentucky. The plant’s primary function is to disinfect both municipal and industrial wastewater, prior to introducing the water back into the Ohio River.

The plant had been using a UV System to disinfect their effluent, and although it is in good working order, issues arose due to the industrial loading. The plant gets heavy industrial flow containing a significant number of contaminants, and the UV System was simply unable to reliably meet mandated disinfection requirements.

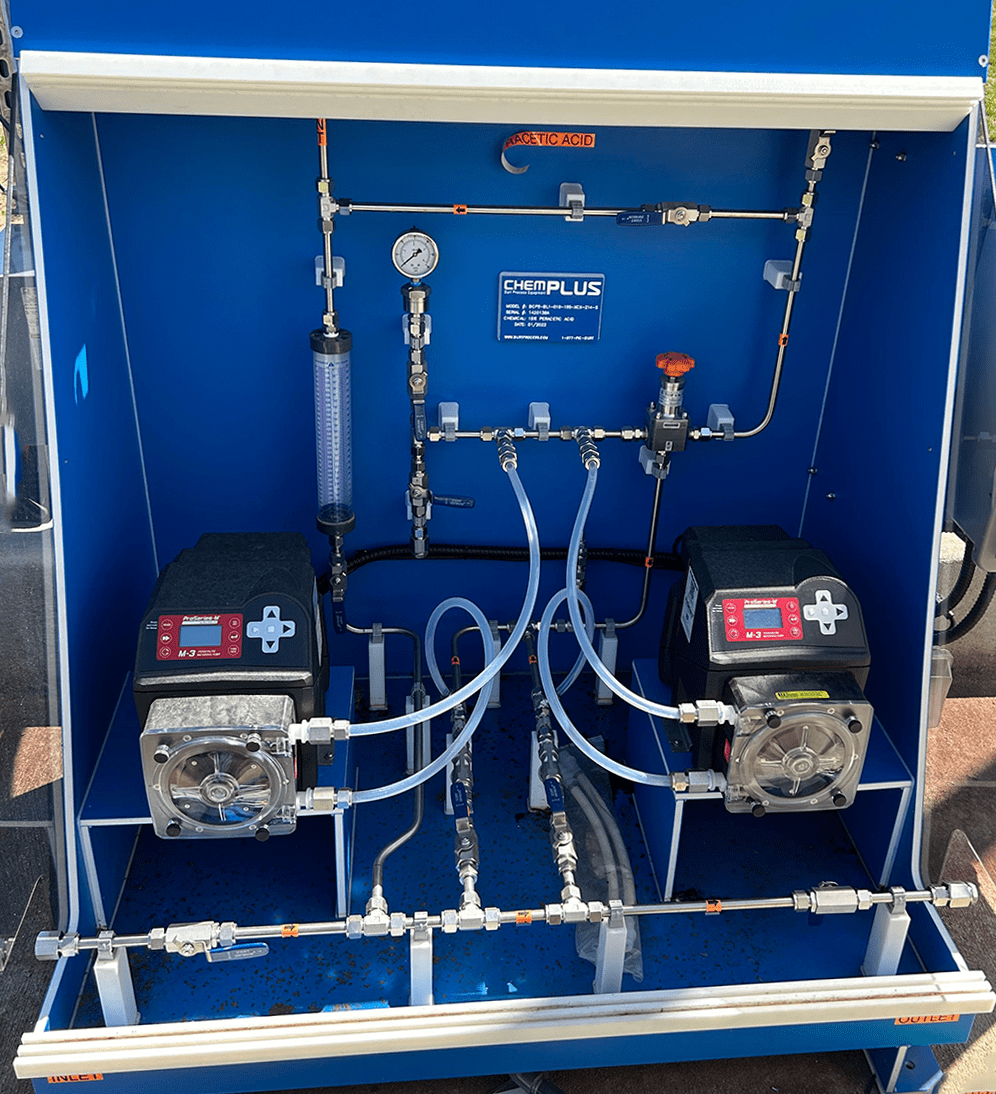

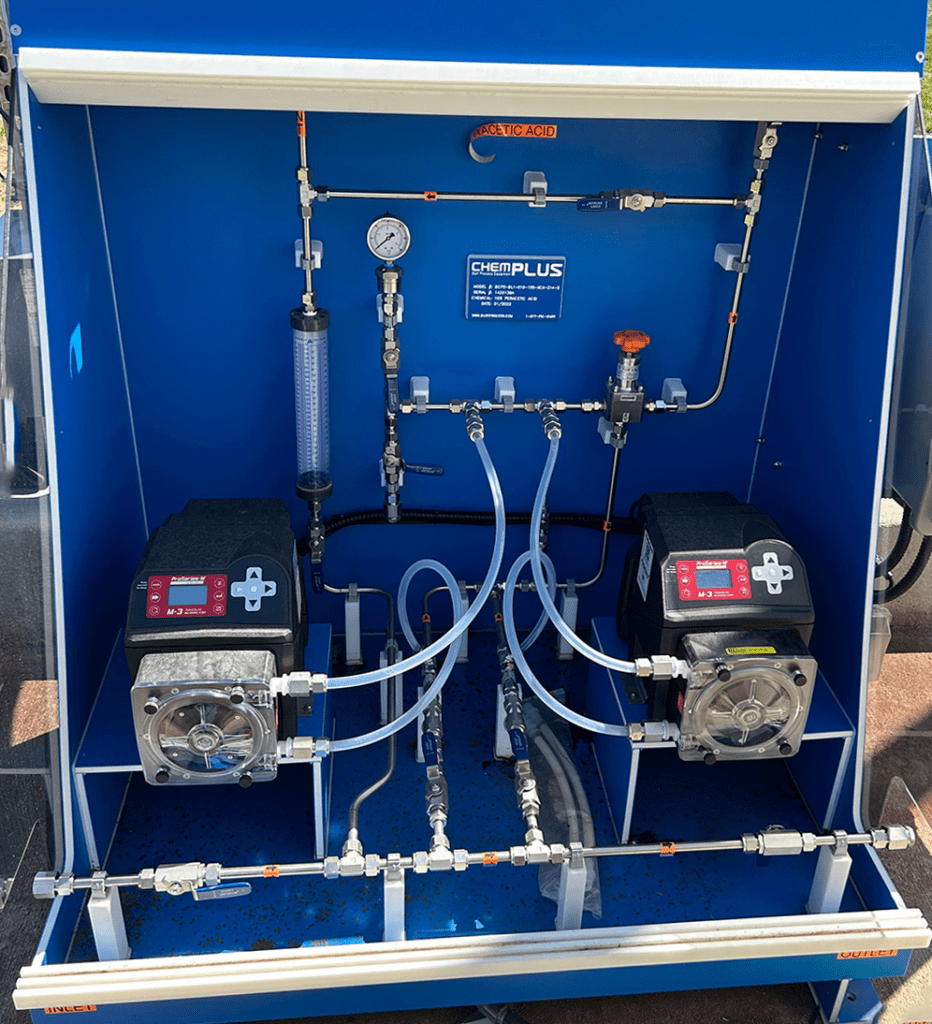

The Plant Manager contacted a local firm, Pelton Engineering, to discuss a solution. Because the UV System could not adequately meet the disinfection needs, the technician opted to make the switch to a chemical treatment solution, and installed a Duplex Skid System equipped with two Blue-White® FLEXFLO® M3 Peristaltic Metering Pumps.

The chemical chosen to deliver reliable disinfection of the wastewater is Peracetic Acid (PAA) at 15% solution under minimal pressure.

PAA is an organic chemical made by combining acetic acid with hydrogen peroxide using a catalyst. It has a vinegar-like odor and is typically sold in a solution of acetic acid, peroxide, and water. PAA was first used as a disinfectant in the early 1900s and was registered as a disinfectant with the U.S. EPA in 1985.

Some Benefits of PAA include the fact it is environmentally friendly. When it oxidizes, PAA breaks down into acetic acid, water, and oxygen. This makes it safer to use on effluent that is discharged into source water or other bodies with high levels of organic content. PAA oxidizes almost instantly, so there is rarely any residual chemical after discharge.

For now, there are few regulations that affect the use of PAA, as it breaks down quickly and does not form any known DBPs.

One issue with PAA is that it is an offgassing chemical, this is why a peristaltic pump makes an excellent choice, there are no valves to clog. The FLEXFLO M3 experiences no vapor lock and no loss of prime when dosing PAA.

Another benefit of the M3 is the pump’s broad turn down range and 4-20mA adjustment. These are important considerations because the plant will eventually changeover all systems from UV disinfection to chemical disinfection, and they have chosen to standardize on one chemical feed solution, the FLEXFLO M3 Peristaltic Metering Pump. The pump’s 10,000:1 turn down range means it will easily and successfully meet a broad spectrum of feed rate requirements.

Maintenance and spare sparts inventory are also a consideration. M3 requires very little regular maintenance, just periodic pump tube changes, and the simplicity of changing the M3’s pump tube factored into the WTP’s decision to choose this particular peristaltic pump. Spare tube assemblies are the only parts inventory needed.

Since the switch to a Duplex Skid System featuring the innovative FLEXFLO M3 Peristaltic Metering Pumps, the WTP is experiencing reliable disinfection of wastewater and meeting all disinfection requirements.

Written by:

Blue-White® Industries

714-893-8529

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

BW®’s Rich Hopkins just completed startup of this wall mount skid, equipped with Blue-White®’s

There are many industrial and municipal applications where accurately measuring fluid flow

It was a busy few days in Honolulu for the Pacific Water

Copyright © 2024 Blue-White

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|