Visit BW® at Aquatech Amsterdam for Expert Chemical Dosing Solutions

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

Chemical metering pumps are a critical component in water treatment systems, where precise and reliable dosing is essential. The performance of these metering pumps can be heavily influenced by the kind of motor used in manufacturing. There are several types of motors that can be employed in chemical metering pumps, such as stepper motors, AC induction motors, brushed DC motors, and more. Over the past decade or so, brushless DC (BLDC) motors have gained traction as the preferred motor choice. BLDC motors offer improved efficiency, durability, and precision over other technologies. This makes them an ideal choice in chemical metering pumps which are being used in critical and highly regulated industries.

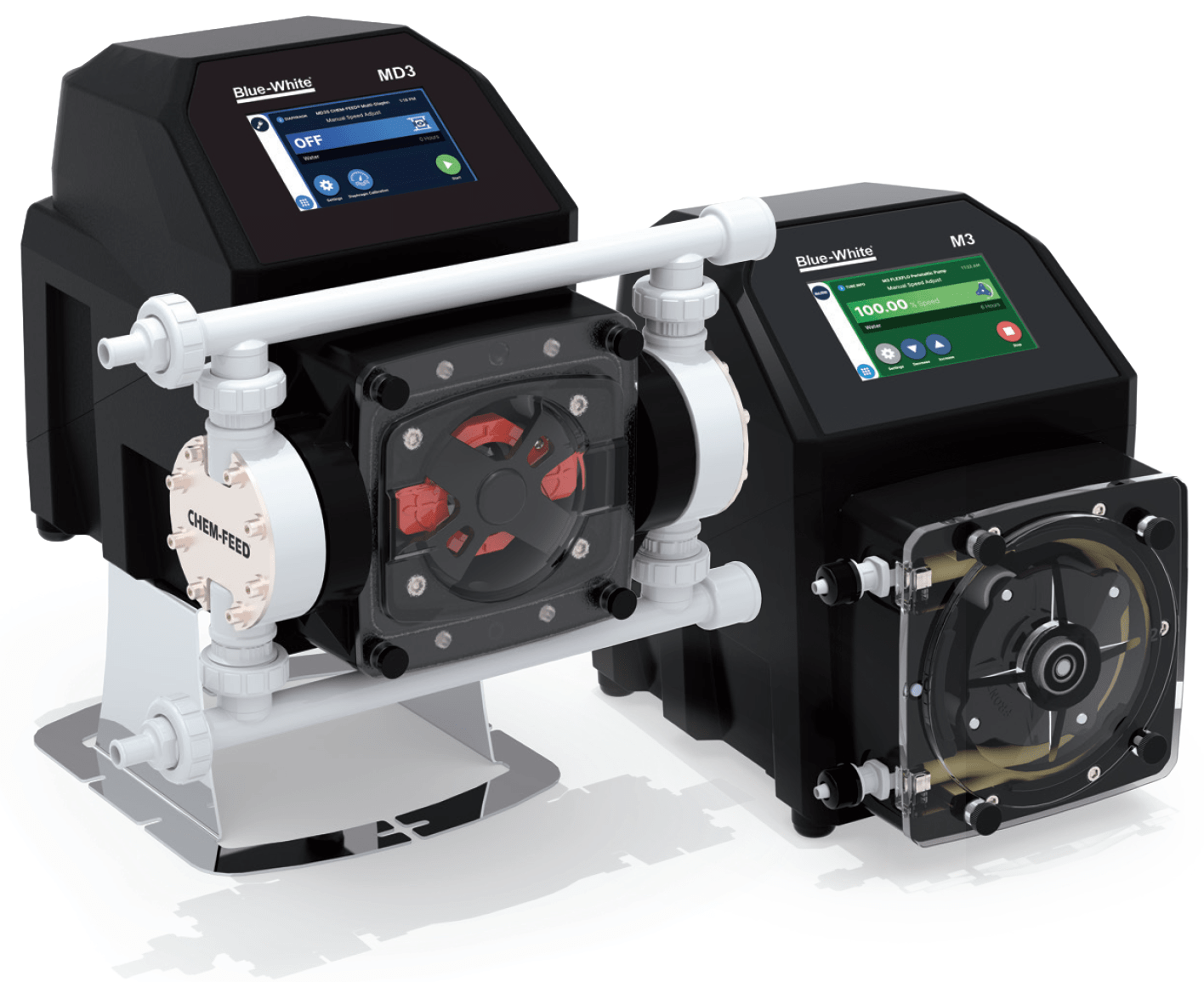

BLDC motor technology is particularly well-suited for use in both peristaltic pumps, where smooth and consistent squeezing of the tubing is essential for accurate fluid delivery, and in diaphragm pumps, where BLDC motors contribute to a wide turndown ratio. A wide turndown ratio enables precise control of flow rates, which is crucial when precise dosing of chemical, and/or dosing in variable quantities are critical.

Still, some manufacturers and end-users shy away from BLDC motors due to the upfront cost. For that reason, it is important to understand how this technology works and how the longterm benefits justify the higher price tag.

BLDC motors combine permanent magnets on the rotor with a series of electromagnets arranged in the stator. The motor’s controller drives the stator windings, generating a rotating magnetic field. This field interacts with the permanent magnets on the rotor, causing it to spin. The absence of brushes reduces mechanical friction, which not only improves efficiency but also eliminates the maintenance issues typically associated with the wear and tear of brushes.

While BLDC motors offer superior performance, they come with a higher degree of control complexity. A BLDC motor requires a feedback mechanism, such as an encoder or sensor, to continuously monitor the rotor’s position. This closed-loop control system ensures the motor operates smoothly and maintains the correct speed. Without proper feedback the motor could stall, reverse, or fail to maintain a steady speed. Thankfully, this challenge is tackled at the manufacturer level, and end-users should expect to receive a system with an easy-to-use interface.

The advantages of this technology far outweigh the additional cost, and include:

Energy Efficiency. Unlike older motor types such as AC shaded-pole motors, which can waste significant energy in the form of heat (with efficiencies as low as 30%), BLDC motors are designed to maximize the conversion of electrical energy into mechanical work. They typically achieve efficiencies between 90% and 93%, which means only a small percentage of the energy input is lost as heat. This reduces energy consumption, which is especially important for applications where pumps may run continuously or for long periods.

Maintenance and Longevity. BLDC motors have exceptional durability. Unlike brushed DC motors, which rely on mechanical brushes that can wear out over time, BLDC motors have no brushes or other parts that are subject to wear and tear. The lack of brushes also means there is less friction, resulting in less heat generation, lower noise levels, and minimal maintenance requirements. All this means they can operate for tens of thousands to hundreds of thousands of hours without significant degradation. In practical terms, this results in reduced downtime and maintenance costs for pump systems.

While other components of the pump will still require maintenance, the motor can remain maintenance-free for years.

Precision Control and Smooth Operation. Accurate dosing relies on precise control of motor speed and torque. In a BLDC motor there is a direct relationship between the voltage applied and the rotor’s position, which allows for the tightest control over rotational speed. In addition, unlike stepper motors, which operate in discrete steps (resulting in a “stuttering” motion that can compromise smooth flow), BLDC motors provide continuous, non-interruptive rotation. These two factors combined ensure a smooth, steady flow of fluid, enabling consistent chemical delivery throughout the entire dosing cycle.

Reduced Noise and Vibration. An often-overlooked benefit of BLDC motors is their quiet operation. The lack of frictiongenerating brushes allows these motors to generate less mechanical noise and vibration. The reduction in vibration also contributes to the overall reliability and comfort of the pumps they power.

Strong Return-On-Investment (ROI). Despite the higher upfront cost of BLDC motors as compared to traditional AC or stepper motors, the long-term benefits make them an excellent investment. The combination of energy efficiency, low maintenance, and precise control leads to lower operating costs and increased uptime, resulting in a quick ROI for users.

BLDC motors offer a host of advantages for chemical metering pumps, including exceptional energy efficiency, extended lifespan, low maintenance, and precise control. For end-users seeking a pump solution that balances performance with long-term value, BLDC motors present a compelling option that improves the efficiency of chemical delivery in critical applications.

All Blue-White® Smart CHEM-FEED® Diaphragm Pumps, and Smart FLEXFLO® Peristaltic Pumps are equipped with Top Performance BLDC Motors for Smooth, Quiet and Precise Chemical Dosing and zero motor maintenance.

Written by:

Blue-White® Industries

714-893-8529

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

BW®’s Rich Hopkins just completed startup of this wall mount skid, equipped with Blue-White®’s

There are many industrial and municipal applications where accurately measuring fluid flow

It was a busy few days in Honolulu for the Pacific Water

Copyright © 2024 Blue-White

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|