Water Disinfection Pumps & a Visit from ACE Mascot Eddy

It was a busy few days in Honolulu for the Pacific Water

Water treatment is technology-driven and heavily regulated. But that doesn’t mean every aspect needs to be complicated or overly costly.

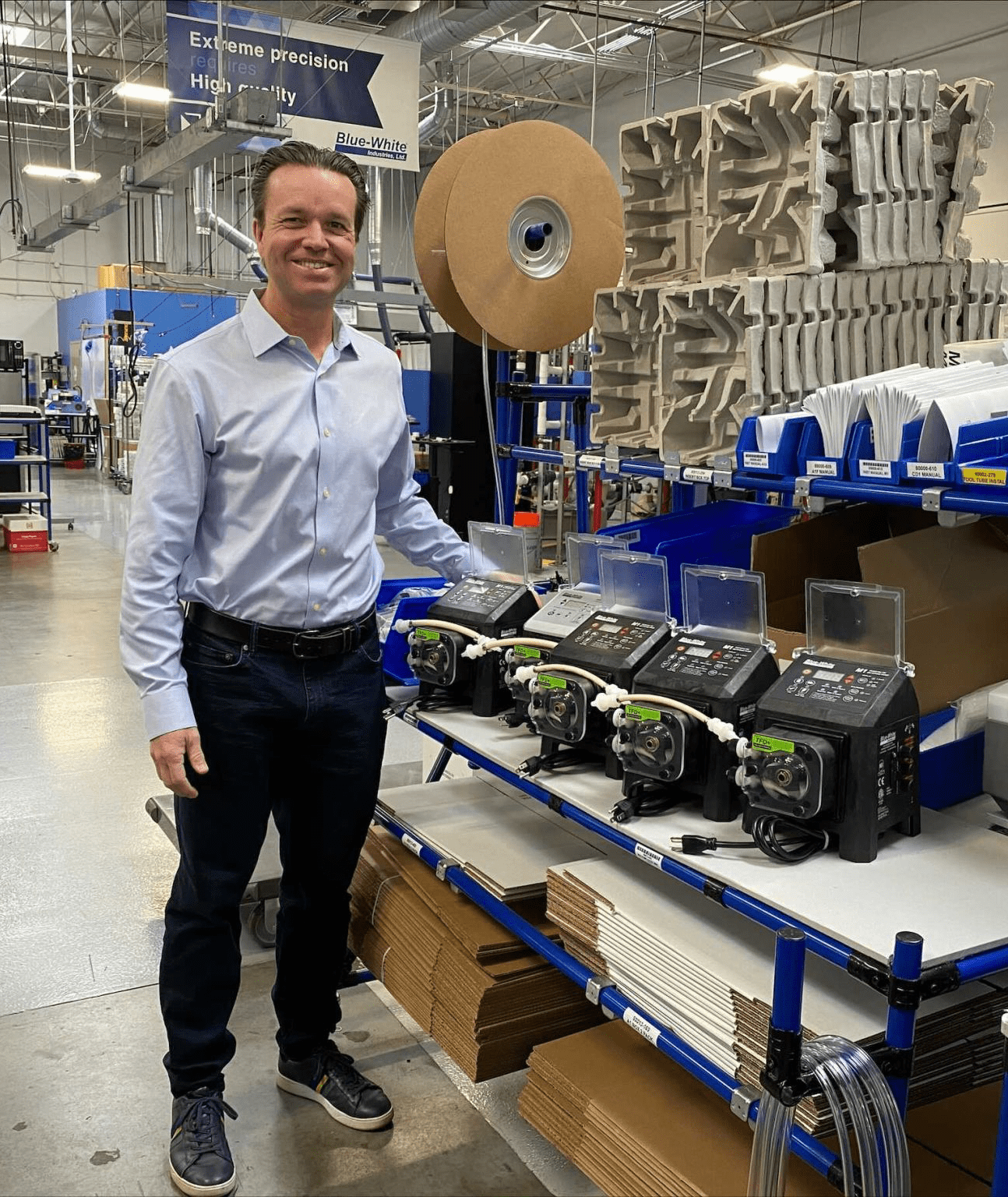

For wastewater plants requiring metering pumps to dose treatment chemicals for processes such as disinfection, filtration, clarification, coagulation, and flocculation, Blue-White offers a solution that allows operators to standardize operations to one chemical feed solution — the FLEXFLO M1 Peristaltic Dosing Pump. The self-priming M1 delivers smooth, consistent, and precise chemical dosing with no danger of vapor lock or loss of prime. It’s the solution to an industry need, according to Blue-White’s Director of Engineering, Patrick Murphy.

“The concept for M1 began when we realized that many municipalities were using our A-100N pumps to meet their chemical feed requirements, a pump that is intended for industrial use not municipal,” says Murphy. “We then reached out and listened to our customers for feedback regarding what they wanted in a feed pump. Requirements included NEMA 4X rating, relay alarms, remote/stop capabilities, NSF 61 rating and LCD cover to protect from chemical residue. We also took what we learned from our motor development projects to incorporate our energy-efficient brushless DC motor as well. This gave us the power we required while requiring less energy to drive the pump.”

The M1 has 4-20mA SCADA inputs and offers a feed output range of .0001 to 5.6 gph, pressures to 100 psi and a high energy efficiency rating. The pump achieves a 10,000-to-1 turndown ratio and is powered by efficient BLDC motor technology. According to Murphy, the pump is typically utilized at smaller municipalities or small well sites. It fits across multiple applications because it has different tubes that make it versatile enough to work with many typical water treatment chemicals, polymers and off-gassing chemicals.

“It is a simple-to-operate pump with a broad turndown ratio. It has simplified ordering because one tube will have a wide range of flow rates that it can operate in,” says Murphy. “Gone are the days of having several different tube assemblies to cover all the ranges of flow rate requirements.”

A sealed enclosure and a display shield protect the pump’s easy-to-operate controls from chemical spills and splashes. In addition, the enhanced Tube Failure Detection System (TFD+) senses tube rupture with no false triggering.

Written By:

Jeanne Hendrickson, Blue-White Industries

It was a busy few days in Honolulu for the Pacific Water

In January Blue-White attended the Pool Show in Atlantic City and displayed

Steve Hernandez /WaterWisePro and Blue-White®’s own Rich Hopkins proved they’re winners. The pair went up

We’re excited to announce we’ve resumed shipment of CHEM-FEED® CD1 and MD1

Copyright © 2024 Blue-White

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|