Visit BW® at Aquatech Amsterdam for Expert Chemical Dosing Solutions

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

Flow rate is a product of the velocity of a fluid and volume. Although flow meters may seem to be a modern development, basic types were evident as far back as the early Roman era. They were often used for measuring water flow to households, and the mathematical foundations of flow theory were evolved during the 17th century.

Today, there are many types of flow meters available: variable area; positive displacement; ultrasonic; and mass flow meters, to name a few. Each type has its special features, and there is no one, universal or perfect flow meter appropriate for all industries. The correct flow meter for the job is the one that will perform adequately and efficiently in the system where it is being used, and at a reasonable cost.

Variable Area style flow meters offer several advantages over some more costly and technical types, making them the flow meter of choice for many flow measurement applications.

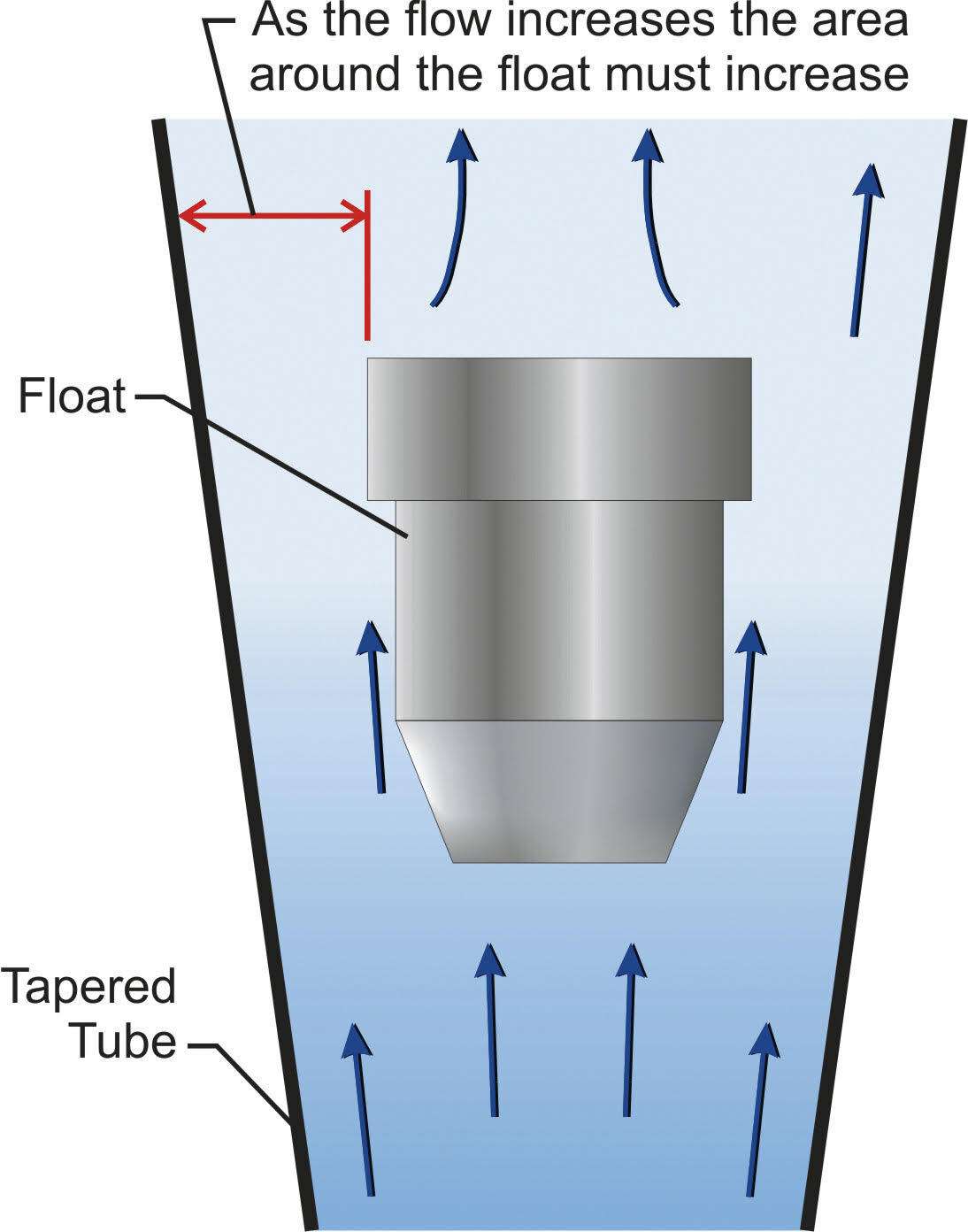

Variable Area Flow Meters utilize a vertically tapered tube through which the fluid to be measured passes, from the smaller diameter end of the meter vertically to the larger diameter. As the fluid flows through the tube it forces an indicator (float) upward. The clearance space (area) between the float and tube increases as the float approaches the top of the meter. This increasing area requires a larger amount of fluid to force the float higher. By varying the taper of the tube, the mass of the float, and the length of the tube, different flow ranges can be calibrated.

The variable area flow meter must obviously be plumbed into a piping system properly: that is, with the narrow part of the taper at the bottom. In the case of Blue-White flow meters you will note that, printed directly onto the tube are the flow increments (scale). The flow rate is read by matching the increments on the tube with the edge of the float.

In recent years, variable area flow meters have become very competitively priced, and because these meters offer such excellent value, more manufacturers of water treatment systems are including them as part of their standard package.

The makers of ultra filtration equipment (reverse osmosis systems) use flow meters to measure output through the membrane, and also to measure reject. The meters play a critical role in helping to monitor the efficiency of the system.

Flow meters offer an advantage over pressure gauges in filtration systems because they measure actual flow; as the filter becomes saturated (full), the flow rate drops, so, just a glance at the flow meter tells the operator if the filter needs cleaning, cartridges need replacement, or if there may be another problem, such as a tear in the filter material or a broken pipe.

Ultra pure water is used extensively in the manufacture of printed circuitry (cleansing of computer chips in particular. Flow meters are used both in the manufacturing and management of deionized water.

Solar-panel manufacturers recommend certain flow rates for optimum performance. Variable area flow meters allow the installer and operator to monitor flow economically, thus enabling critical process adjustments to be made.

Without proper knowledge of what these terms mean, it is easy to overbuy, or under buy a Flow Meter. It’s important to understand the terminology used in the flow industry to avoid being misled. In plain terms accuracy really means error. Flow meter manufactures may simply state their flow meter is 2% accurate, you need to question that statement, 2% of what? Indicated flow? Or 2% of full scale? These two seemingly similar accuracies are very different and could be costing you extra money.

Repeatability is different than accuracy and in many cases more important to industry. Repeatability is the meter’s ability to reproduce flow rates consistently under the same conditions. Repeatability is paramount in the processing industry where tracking flow changes is crucial.

Many circumstances can affect flow meter accuracy, for example, specific gravity (‘weight’) of the liquid will affect the flow meters’ reliability and accuracy. Viscosity, the degree to which a fluid resists flow under applied force, also affects accuracy, as do elevated temperatures.

Be certain to check chemical compatibility. Don’t rely on compatibility charts, do your own testing. Many flow meter manufacturers are willing to provide material sample kits to assist in conducting these tests. Blue-White recommends you seek assistance from your supplier to ensure you select the correct flow meter for your particular applications’ conditions.

Written by:

Blue-White® Industries

714-893-8529

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

BW®’s Rich Hopkins just completed startup of this wall mount skid, equipped with Blue-White®’s

There are many industrial and municipal applications where accurately measuring fluid flow

It was a busy few days in Honolulu for the Pacific Water

Copyright © 2024 Blue-White

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|