Visit BW® at Aquatech Amsterdam for Expert Chemical Dosing Solutions

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

Many water treatment plant upgrades and purchasing decisions are entirely determined by the price. However, long-term costs such as energy and maintenance, are often not considered in the initial stages. This potentially leaves water treatment plants with ongoing and reoccurring expenses, which could result in higher energy bills, increased purchases of spare parts, and operator labor time.

The City of Lompoc Water Treatment Plant analyzed the long-term potential cost savings if all of these ongoing expenses were taken into consideration, and they saw those efforts pay off.

The City of Lompoc Water Treatment Plant, located in Lompoc, California, treats approximately 3 million gallons of water per day during the low-demand season and 4.5 MGD during the high-demand season. The plant currently has 1,019 active service connections in its distribution system, servicing approximately 43,500 residents.

The city had been operating its Chlorine injection process with a more than ten-year-old system. After a multi-point failure in their Chlorine injection system, which caused an overdose, an in-depth evaluation of their process was performed. It was discovered that a failure of ancillary items allowed for the chemical to be gravity fed into the system, causing this overdose.

After analyzing where the failures occurred, it was decided to switch to a more advanced, more cost-effective product. The Plant Operators were looking to reduce power consumption, simplify maintenance, increase reliability, enhance flow control, simplify SCADA interface, and remove ancillary items in their system.

By switching to Blue-White® Industries FLEXFLO® M3 peristaltic pumps, they were able to achieve these goals.

Prior to the purchase of the new peristaltic chemical metering pumps, the plant was using diaphragm pumps, which were driven by a 1 horsepower motor. In order to reduce the power consumption of the chemical metering pump in use, the City of Lompoc chose Blue-White peristaltic metering pumps which use a highly efficient ¼ horsepower 3-phase brushless DC motor. Operating on a 115VAC voltage source with a max amperage draw of 13.6A, the 1 horsepower diaphragm pumps were consuming approximately 1,564 Watts of power. This resulted in energy costs of approximately $2,075.00 per year.

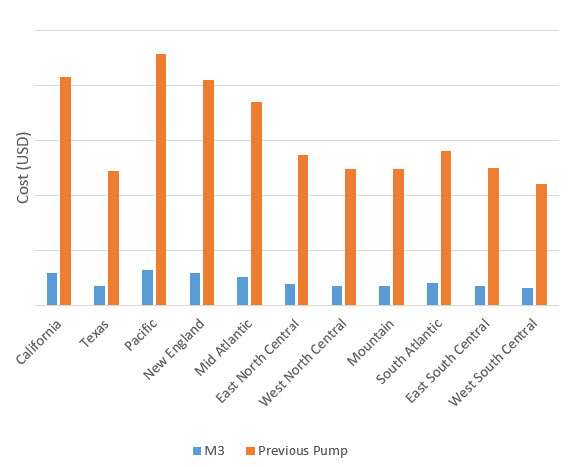

The FLEXFLO M3 peristaltic pump operates on the same 115VAC power source but has a maximum amperage draw of 1.913A and consumes approximately 220 Watts, leading to an estimated energy cost of $300.00 per year. This results in savings to the plant of nearly $1,775.00, or 710%, in energy costs. The payback on the M3 pump is achieved in less than two and a half years. The data provided is based on California rates, and energy costs will vary depending on locations within the USA (shown in Table 1). However, the percentage of savings will remain constant.

The amperage draw of each pump can vary with the change of pressures and outputs, as the load on the motor will cause it to draw more or less, depending on the application. For example, using a soft material tube operating at approximately 13% motor speed, the on-site amp draw was measured at 0.1A.

While energy costs played a key role in determining which pump to purchase, maintenance costs were also considered. Unlike diaphragm pumps, check valves are not required for peristaltic pumps in order to prevent backflow or siphoning.

In addition, chemicals that contain particulates or calcify are detrimental to diaphragm pumps as valves can become clogged. This leads to ongoing maintenance requirements and expenses, including; cleaning, replacement of parts, or even a pump failure. However, peristaltic pumps rely solely on the squeeze of the pump tube to prevent this unwanted backflow or siphoning. The compression of the tube also enables the pump to move particles through the fluid path.

Although the tube is a wearable item, a periodic tube change is the only ongoing maintenance requirement for the pump. This procedure can be completed in less than five minutes.

The City of Lompoc is currently using an NKL tube, which costs less than $60. The minimal maintenance requirement enables operators to focus their time and effort in other areas of the operation, which is a valuable cost-saving.

In addition to reducing maintenance costs, the plant simplified its process by removing ancillary items. The backpressure and air relief valves were removed from the sodium hypochlorite system because peristaltic pumps do not require them for operation. Since diaphragm pumps lose output when pumping against pressure, a back pressure valve is a common item used to maintain a consistent output as system pressures can vary. This can result in a fluctuation in chemical dosing. By comparison to a diaphragm pump, the M3 does not lose output against pressure, the compression and rotation of the roller against the tube positively displaces the fluid.

Diaphragm pumps are also prone to vapor locking, especially when exposed to gaseous chemicals such as sodium hypochlorite. Because there is no vapor-lock condition, air or gas relief valves are not required on the FLEXFLO® M3 pump. The M3 is able to move trapped gases through the fluid path.

While the M3 can be used in various applications, it was specifically designed for use in municipal water and wastewater treatment applications.

Water treatment plants rarely mimic the process from one plant to another. This was considered when the M3 was in its initial design phase. So using one standard pump head size, the M3 allows for 12 interchangeable tube options, and provides exceptional chemical compatibility with those chemicals commonly used to treat water and wastewater.

Because of the versatility of the FLEXFLO® M3, low maintenance costs, advanced motor technology, SCADA interface, and reduced power consumption, the M3 peristaltic pump has proven to be an excellent choice for the City of Lompoc.

Download (PDF)

Team Blue-White® is at Aquatech Amsterdam and ready to discuss the Best

BW®’s Rich Hopkins just completed startup of this wall mount skid, equipped with Blue-White®’s

There are many industrial and municipal applications where accurately measuring fluid flow

It was a busy few days in Honolulu for the Pacific Water

Copyright © 2024 Blue-White

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|