Industrial

C-600HV

Operation

Priming the Pump

It is recommended to prime the pump before use. Before priming the pump, or starting the pump, be sure that all safety procedures are followed. Wear protective eyewear and clothing, and familiarize yourself with chemical and local safety protocols.

- Ensure the suction line is connected properly and check that the discharge is open and free of obstructions.

- Priming is best when the pump is run at 100% output with discharge tubing removed from system pressure.

- Wet pump head valves before priming for best results.

- Start the pump and run until the solution has entered the pump head.

- Stop the pump and re-connect the discharge tubing to the pump and/or injector.

If the pump does not prime or does not hold prime, check the suction line for clogs, obstructions, or leaks. Check the foot valve for proper vertical installation.

Manual Operation

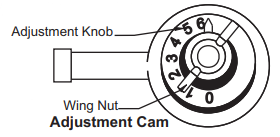

The pump is shipped for installation and integration into customer-provided wiring and controls. Ensure you are familiar with the control system before operating the pump. Adjust pump output by adjusting the cam on the pump head.

- Make sure the pump is off before adjusting.

- Loosen the wing nut.

- Turn the adjusting knob so the pointer is on the desired setting. Note: pump less chemical at first, then re-adjust.

- While holding the knob, tighten the wing nut to keep the knob at the desired setting. Note: wing nut must be tight

Calibration

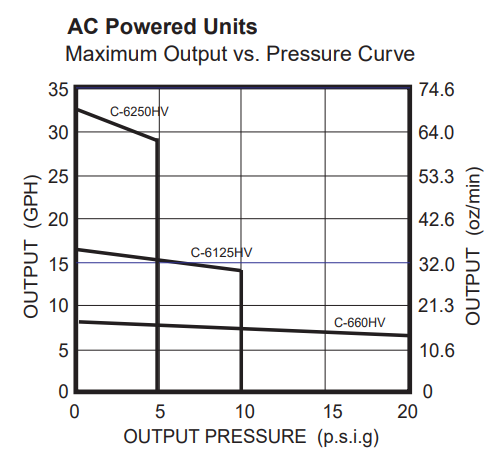

To ensure the most accurate pumping, a pump calibration is recommended prior to operating the pump. The C-600HV pump flow rate will vary depending on the system pressure. (Note: If system pressure varies frequently, a back-pressure valve will be necessary to ensure consistent flow accuracy.)

To calibrate the pump:

- Fill a calibration column or graduated cylinder with solution. Note the level of the fill.

- Run the pump at a set speed for 1 minute against the actual system pressure.

- Record the flow difference in the calibration cylinder.

- Calculate the flow rate by dividing the flow by the time. For example, if the pump runs for 1 minute, and the flow difference is 30 ml, then divide 30ml by 1 minute. The flowrate is 30 ml/min.

- For best accuracy, run more than one calibration to check results, or run another calibration at a different pump output.

Calibration results should be close to the flow curve (below), but can vary depending on chemical composition, viscosity, temperature, and other conditions.

- Ask me a question!