Industrial

C-600P

Installation

What’s in the Box

The C-600P Pump is shipped with the following contents:

- C-600P Diaphragm Metering Pump

- Discharge injection fitting with check valve

- Suction tube – clear PVC – 5′ length (3/8″ OD, 1/4″ ID)

- Suction foot valve/strainer

- Suction ceramic weight

- Discharge tube – opaque polyethylene – 5′ length (3/8″ OD, 1/4″ ID)

Preparation

The C-600P Pump is designed to be installed indoors in a protected enclosure for maximum pump life. A cool, dry location where the unit can be easily monitored is recommended. Special ventilation is not required.

The pump can be mounted on a level surface or mounted where the pump head is vertical, with suction at the bottom and discharge at the top.

Piping and physical installation

The C-600P Pump must be level with discharge facing up to ensure pumping accuracy. Choose a location that minimizes suction lift.

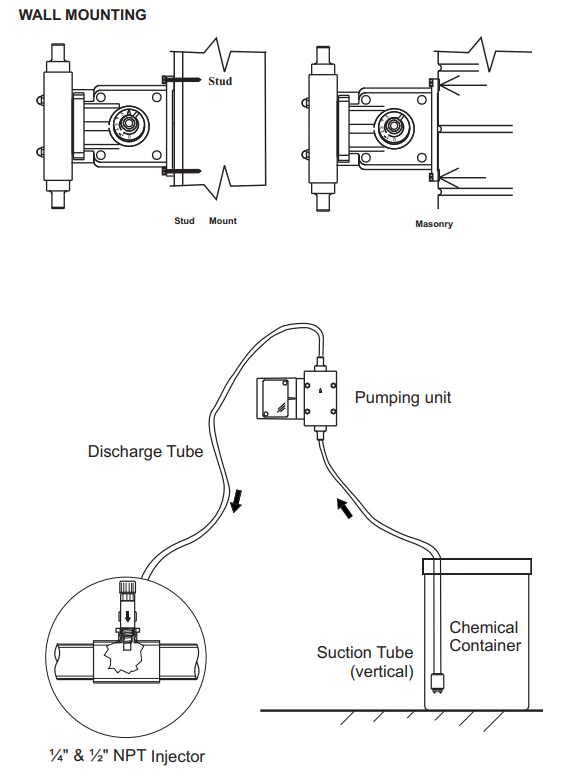

If mounting the pump to the wall or bracket, follow these instructions:

- Use the diagram and drawing on the manual (or below) to mount the bracket to a secure wall location. We recommend mounting the pump at a height where the adjustment dial is easily visible and where it can be easily serviced.

- Ensure the pump is mounted level and screws are secure and will support the weight of the pump and any connected tubing.

- The pump can also be mounted to a customer-provided bracket and structure. Be sure the pump is mounted so it can easily be adjusted (via cam) and serviced.

Connecting Suction and Discharge Tubing/Piping

The C-600P Pump comes with 1/4’” x 3/8” tubing connections.

Before connecting the tubing to the pump, be sure the pump is OFF. Wear protective clothing and eye protection when connecting tubing to chemicals or chemical lines.

Connect the suction tubing to the pump, and place and secure the other end of the suction tubing in the chemical tank/source. Using the provided foot valve/strainer and weight is recommended.

Connect the discharge tubing to the pump and then connect the other end to the discharge point. If using the provided injection valve, be sure to mount it in an upward position to prevent air bubbles from collecting.

Wiring

Power Wiring

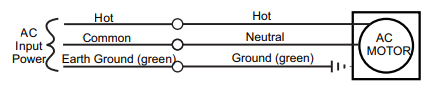

The C-600P can be provided with a motor powered by 100 to 240VAC, 50/60Hz power. There is no power cord provided. The pump must be field-wired using a customer-provided power cord or hard-wired. The pump includes an attached J-box.

Be certain to connect the pump to the proper supply voltage. Using the incorrect voltage will damage the pump and may result in injury. The voltage requirement is printed on the pump serial label.

Note: When in doubt regarding your electrical installation, contact a licensed electrician

See the below Wiring Chart for information and specifications in connecting to your electrical and control system.

Motor Lead Wires

| Input Voltage | Hot Lead wire | Neutral Lead wire | Ground Lead wire |

| 115V 60 Hz | Black or Yellow | Blue | Green |

| 220V 50 Hz | Blue or Yellow | Brown | Green |

| 230V 60 Hz | Black or Yellow | Red | Green |

| 240V 50 Hz | White or Yellow | Orange | Green |

| 24V 60 Hz | White | Blue | Green |

| 12 VDC | Black | White | N/A |

| 24 VDC | Black | White | N/A |

- Yellow lead wire = thermally protected motor, Black/Blue lead wired = standard impedance protected motor.

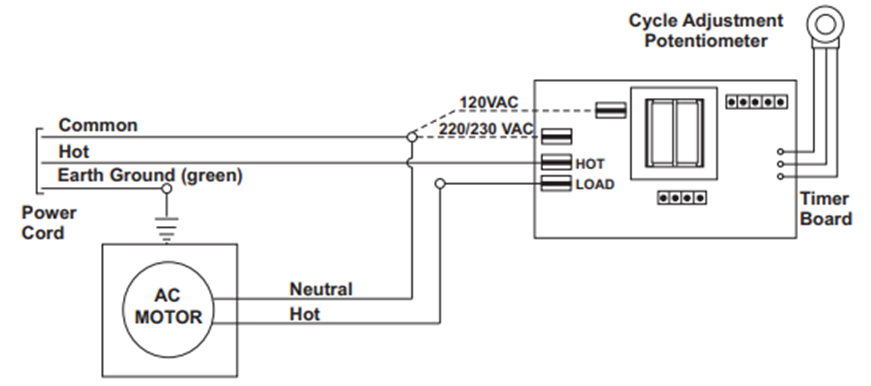

If you have a C-600 with Cyle Time Board (no longer offered), then see the diagram below for wiring instructions.

- Ask me a question!