Municipal

MD3 (Legacy)

Product Specifications

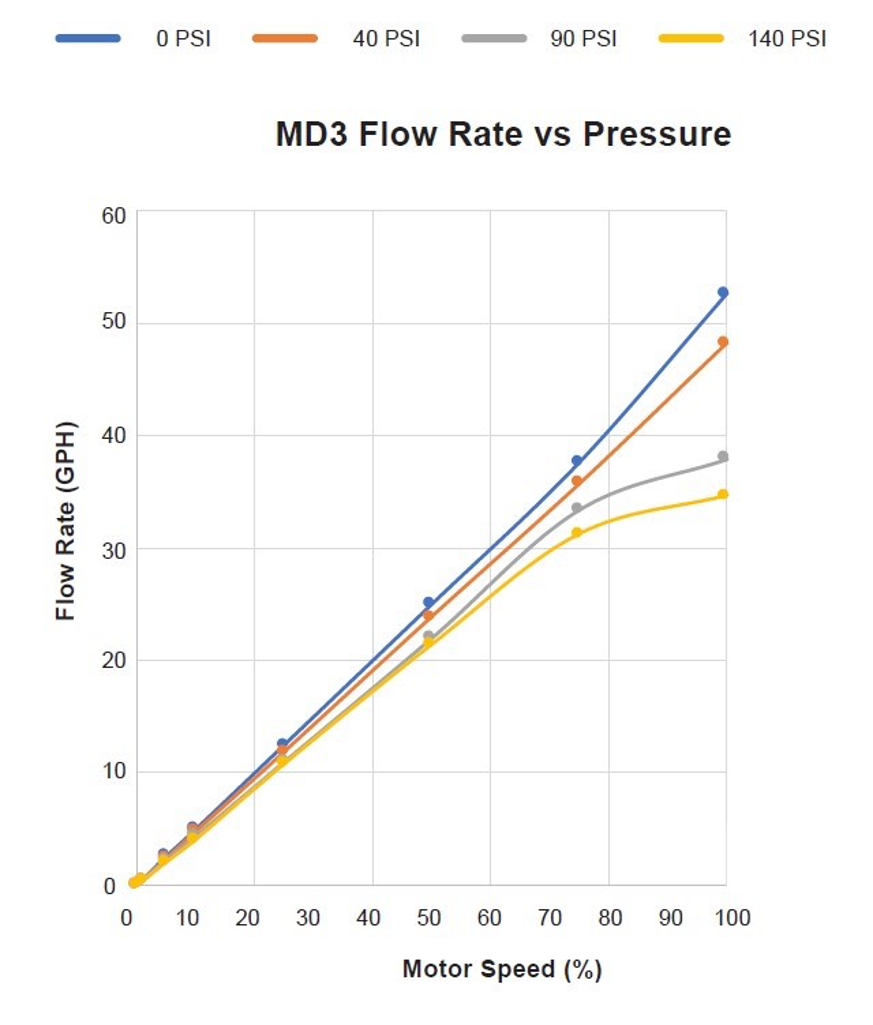

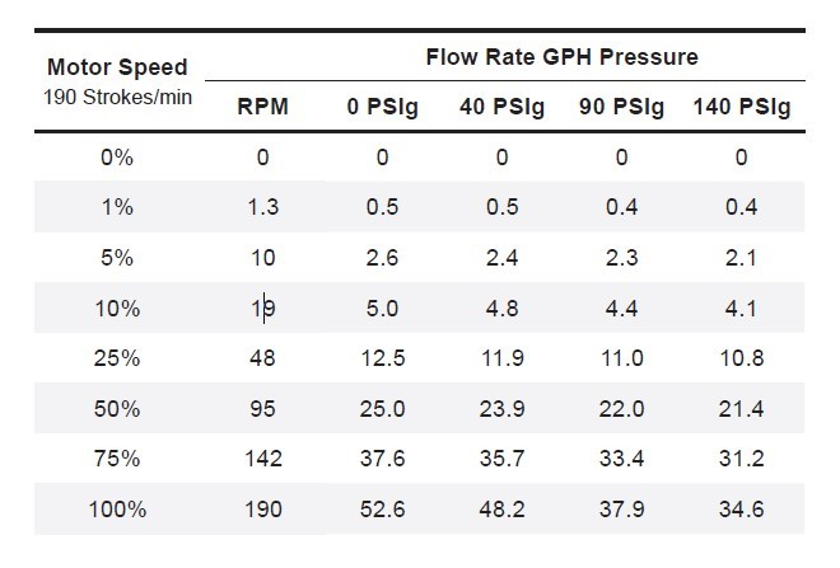

Performance for MD3 (Legacy)

Maximum Flow/Pressure:

- 34.6 gph at 140 PSI

- 37.9 gph at 90 PSI

- 48.2 gph at 40 PSI

- 52.6 gph at 0 PSI

Maximum speed 100% = 190 Strokes/Min

Fitting connections for MD3 (Legacy) pump

“M” = 1/2” Male NPT (Straight and 90-degree elbow)

“B” = 1/2” Hose Barb (Straight and 90-degree elbow)

Maximum Viscosity: 1,000 Centipoise

Maximum Suction Lift: 20 ft at sea level (14.7 atm psi)

Electrical and Controls

Electrical Power Requirement: 100 to 240VAC, 50/60Hz

Motor: Brushless DC, 2,000:1 Turndown, Continuous Duty

Power cord options available (6 feet length):

- 115VAC 50/60HZ, NEMA 5/15 plug (U.S.)

- 220VAC 50/60HZ ,CEE 7/V11 plug (EU)

- 230VAC 50/60HZ, NEMA 6/15 (U.S.)

- 240VAC 50/60HZ, AS 3112 plug (Australia / New Zealand)

- 230VAC 50/60HZ, BS 1363/A plug (UK)

Inputs:

- 4-20 mA – fully configurable

- 0-10 VDC

- Frequency / Pulse input – fully configurable

- Stop/Start Dry Contact Closure (Configurable for N.O. or N.C.)

- FVS (Flow Verification System) (Flow sensor provided by others)

Outputs:

- 4-20 mA output – fully configurable

- Frequency output (Open collector)

- Four (4) Alarm Outputs – Programmable.

Materials of Construction

Non-wetted Components:

- Enclosure: 413 Aluminum (Polyester powder coated) – NEMA 4X (IP 66)

- Drive Enclosure: Valox (PBT) thermoplastic

- Permanently lubricated sealed motor shaft support ball bearing.

- Drive Enclosure Cover: Polycarbonate

- Cover Screws: 300 Series stainless steel

- Pump Head Cover: 316 Stainless Steel

- Motor Shaft: Chrome-plated steel

- DFD System Sensor pins: Hastelloy C-276

- Power Cord: 3 conductor, SJTW-A water-resistant

- Mounting Brackets and Hardware: 316 Stainless steel

Wetted Components:

- Pump Head Assembly: PVDF

- Pump Head: PVDF

- Adapter Connections: PVDF

- Valve Cartridges: PVDF

- Valve Balls: Ceramic

- Elastomers: TFE/P

- Static Seals: TFE/P (optional EP)

- Diaphragm: DiaFlex® (optional Flex-A-Prene)

Diaphragm Options

DiaFlex® Diaphragm – This material consists of a natural PVDF flexible single-layer design that is compatible with most acids and bases. DiaFlex® is not compatible with sodium hydroxide or ammonia.

Flex-A-Prene® Diaphragm – An excellent material for most water treatment applications. Chemically resistant to 50% sodium hydroxide and many others.

Dimensions and Weights

Maximum Overall Dimensions: 16-1/8”W x 15-1/4”H x 15-5/16”D (40.9W x 38.7H x 38.9D cm)

Product Shipping Weight: 53 Lb. (24 Kg)

Agency Listings

- CE

- cETLus

- RoHS Compliant

- NSF 61 Listed

- NEMA 4X

- Ask me a question!