Municipal

MD3

Installation

What’s in the Box

The MD3S Pump is shipped with the following contents:

- MD3S Peristaltic Metering Pump

- Connection fittings kit: (2) 1/2” MNPT straight, (2) 1/2” MNPT 90-degree elbow, (2) 1/2” Hose Barb straight, (2) 1/2” Hose Barb 90-degree elbow, and (2) Union nuts.

- Suction Foot Valve

- Power Cord – 6 feet

- USB Drive (Operating manual)

- Mounting hardware kit

Preparation

The MD3S Pump is designed to withstand outdoor conditions, although we recommend locating the pump in a protected enclosure for maximum pump life. A cool, dry location where the unit can be easily monitored is recommended. Special ventilation is not required.

The pump can be mounted on a level flat surface. We recommend using the provided mounting brackets for secure installation. Blue-White also offers a sturdy polyethylene (PE) <a href="https://www.blue-white.com/product/wall-mount-kit-1-2-3-4-series/" target="_blank" rel="noreferrer noopener">Wall Shelf</a> to mount the pump.

Piping and Physical Installation

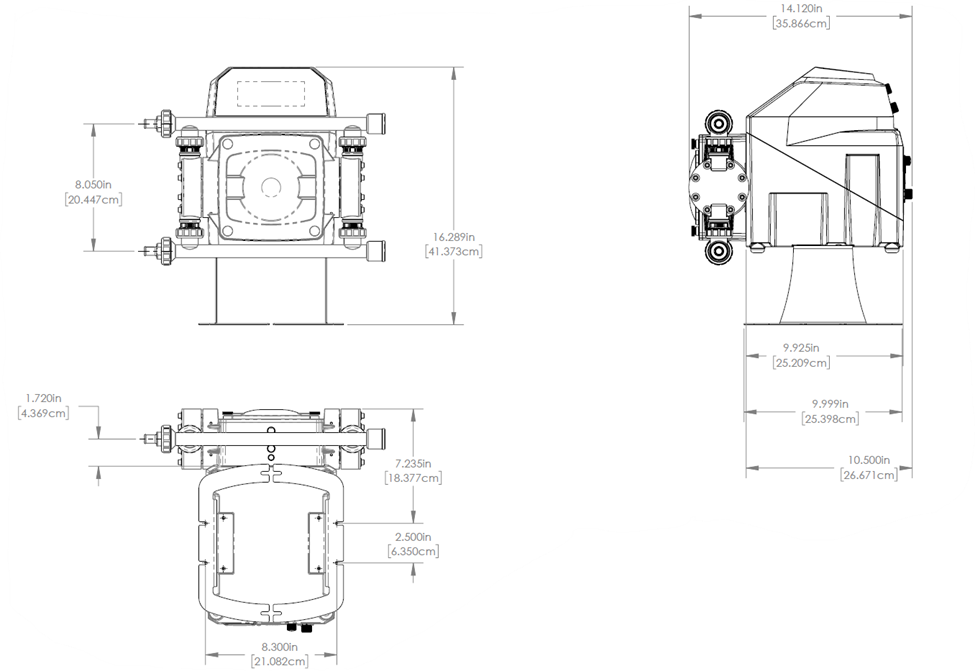

The MD3S Pump must be level to ensure pumping accuracy.

If mounting the pump using the mounting bracket, follow these instructions:

- Use the diagram and drawing on the manual (or below) to mount the pump and bracket to a secure location. We recommend mounting the pump at a height where the display and indicator lights are easily visible, and where it can be easily serviced.

- Ensure the bracket is mounted to the pump first using the provided hardware.

- Ensure location provides enough space for inlet and outlet connections to the pump and ensure enough space for rear wiring.

- Place the pump and secure to the base surface using the appropriate hardware for the base surface.

If mounting the pump to a shelf, be certain the shelf will be able to support the weight of the pump.

Connecting Suction and Discharge Tubing/Piping

MD3S Pump has many options for connection to 1/2” pipe or ½” hose/tube.

“M” 1/2” MNPT connection.

“B” 1/2” Hose Barb connection.

Any injection valve, suction strainer, or tubing must be purchased separately.

Connecting Suction and Discharge Tubing

Before connecting the tubing or piping to the pump, be sure the pump is powered OFF. Wear protective clothing and eye protection when connecting tubing to chemicals or chemical lines.

Connect the suction tubing to the pump, and place and secure the other end of the suction tubing in the chemical tank/source. Using the provided foot valve/strainer and weight is recommended.

Connect the discharge tubing to the pump and then connect the other end to the discharge point. If using the provided injection valve, be sure to mount it in an upward position to prevent air bubbles from collecting.

Wiring

Power Wiring

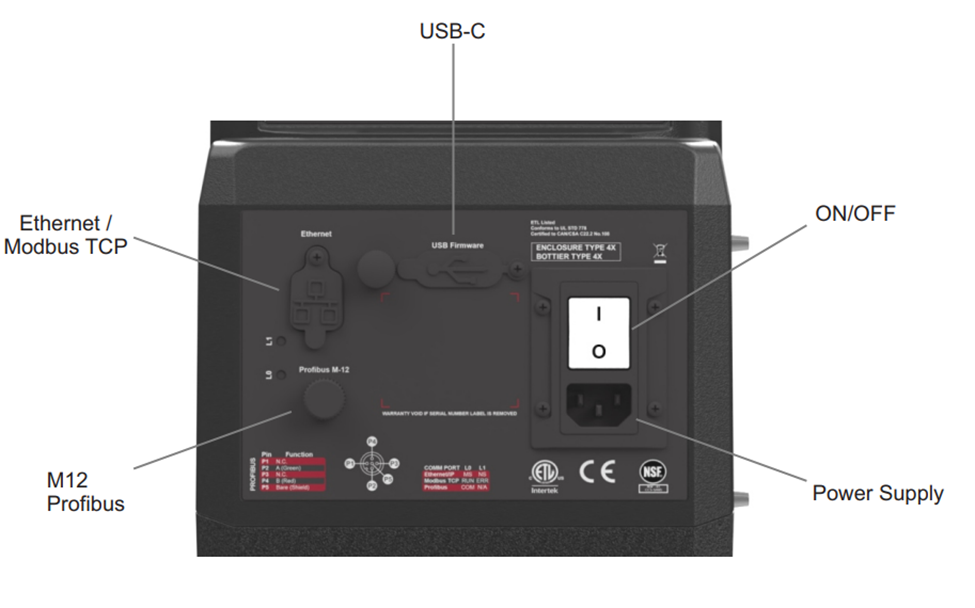

The MD3S is powered by 100 to 240VAC, 50/60Hz power. Use the provided 6’ power cord and attach the cord at the back of the pump.

A removable power cord is included if the pump is ordered with either a “4” 115V 50/60Hz-NEMA 5/15 plug(US), or a “5” 220V 50/60Hz-CEE 7/V11plug. See accessories for alternate power cord options (ordered separately.) If using a power cord not provided by Blue-White, the cord must be IEC C13 rated at 250 volts.

Caution: Consult a licensed electrician when in doubt about your electrical installation.

Control Wiring

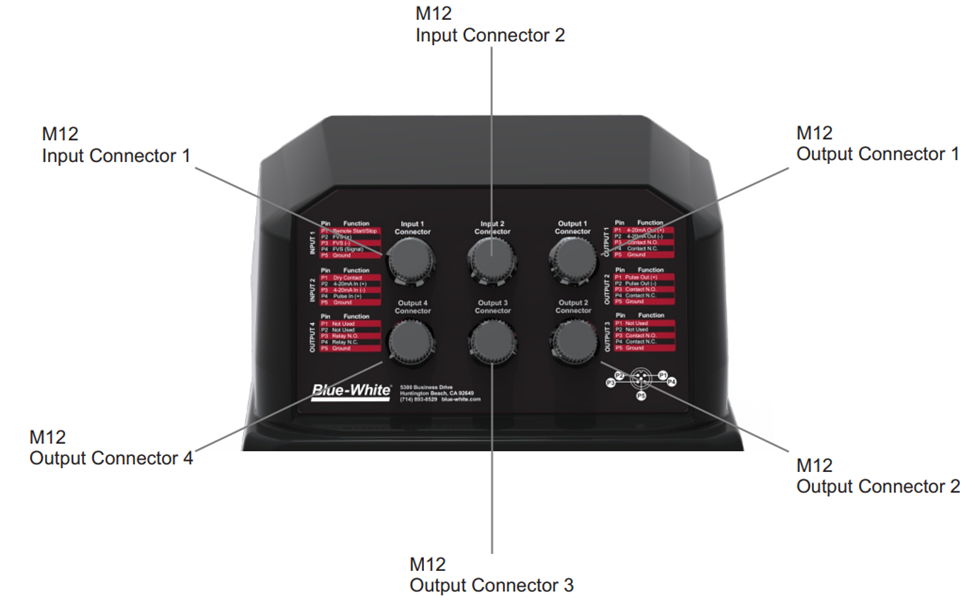

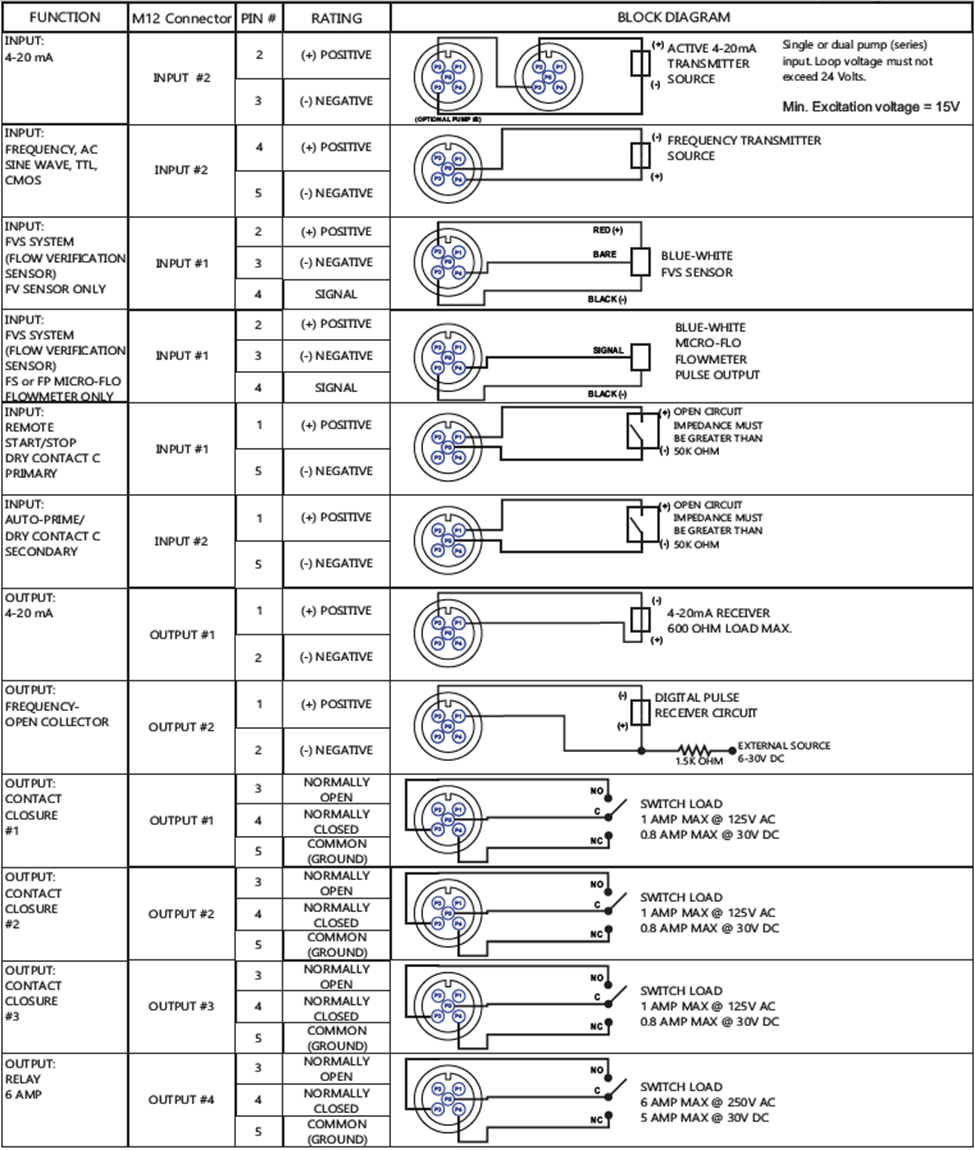

The MD3S pump has six (6) M12 male connectors (5 pin) on the back of the pump for connection to signal wiring.

The M12 connectors must be connected with shielded and insulated M12 cables with a 250VAC voltage rating. (M12 cables are not included with the pump. See accessories or purchase separately.)

Signal connection includes:

Input Signals

- Remote Start/Stop Input (Dry Contact Closure)

- Auto-Prime / Auto-Stop (Secondary Input – Dry Contact)

- FVS (Flow Verification System) Input

- 4-20mA Input (pump speed control)

- Frequency / Pulse Input (AC, Square Wave)

Output Signals

- 4-20 mA output (Pump speed – scalable)

- (3) Output Alarms (Contact closure rated 1 amp, 125VAC) (Programmable)

- (1) Output Alarm (Relay, 6 amp (250VAC) or 5 amp (30 VDC) (Programmable)

- Pulse Output 0-1000Hz (AC, Square Wave)

Communications Wiring

- Ethernet and Modbus connections are made via the Ethernet port on the rear of the pump.

- Profibus connection is made via the M12 Profibus connector at the rear of the pump.

See the below rear panel images and Wiring Chart for information and specifications in connecting to your electrical and control system.

Note: Shielded cables must be used on all signal wiring.

See the below rear panel images and Wiring Chart for information and specifications in connecting to your electrical and control system.

Note: Shielded cables must be used on all signal wiring.

Refer to the instructions in the manual for detailed information.

- Ask me a question!