Industrial

F-300

Installation

What’s in the Box

The F-300 flow Meter is shipped with the following contents:

- F-300 Flow Meter

- Gasket

- Clamps (2)

- Quick Start Guide (QSG)

- Instruction Manual

For video instructions on how to install click here.

Preparation

- Remove the Flow Meter from the box and ensure the gasket and clamps are included prior to prepping any installation. Confirm flow meter is proper for your pipe size and flow.

- Identify the proper location for installation. Note the straight length of pipe requirements. Pipe location should be in an area that allows easy reading of the meter. The pipe needs to be in good condition.

- To prevent debris from entering the meter, install the flow meter downstream from the filter. This is not necessary but is recommended depending on water quality.

Piping and Physical Installation

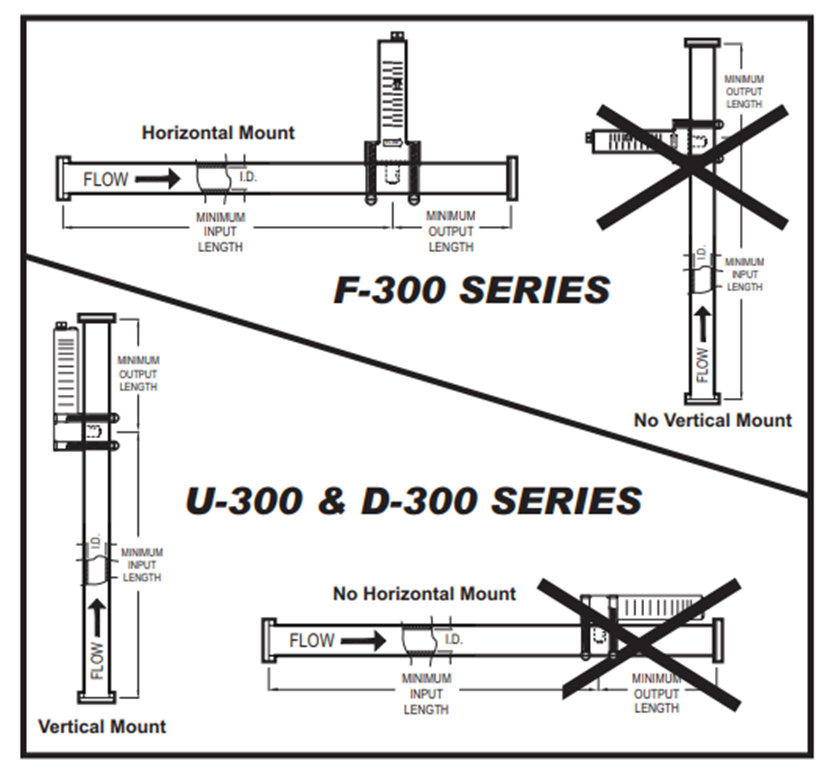

Minimum Straight Pipe Length Requirements The meter’s accuracy is affected by disturbances such as pumps, elbows, tees, valves, etc., in the flow stream. Install the meter in a straight run of pipe as far as possible from any disturbances. The distance required for accuracy is 5 times the nominal pipe diameter before the meter and 2 times the nominal pipe diameter after the meter.

- The meter is designed to withstand outdoor conditions.

- F-300 series meters must be mounted at the vertical (twelve o’clock) position on horizontal pipe only. (Horizontal units only)

- The pipe must be completely full of water at all times.

- The meter can accurately measure flow from one direction only.

Installation

- To prevent debris from entering the meter, install the flowmeter downstream from the filter, if possible, with at least the minimum straight pipe dimensions called for in the above drawing.

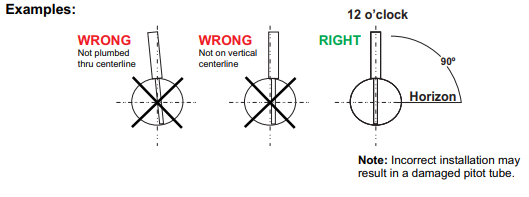

- Drill the pitot tube hole in the top (12 o’clock position) of the horizontal pipe with a 5/8” size drill.

- Carefully remove all burrs. Insert the pitot tube, with the gasket in place, into the drilled hole.

- Tighten the clamps alternately, a little at a time.

- Make certain the flow direction is in the same direction of the flow arrow.

Installing a F-300S / F-300SL Flow Switch

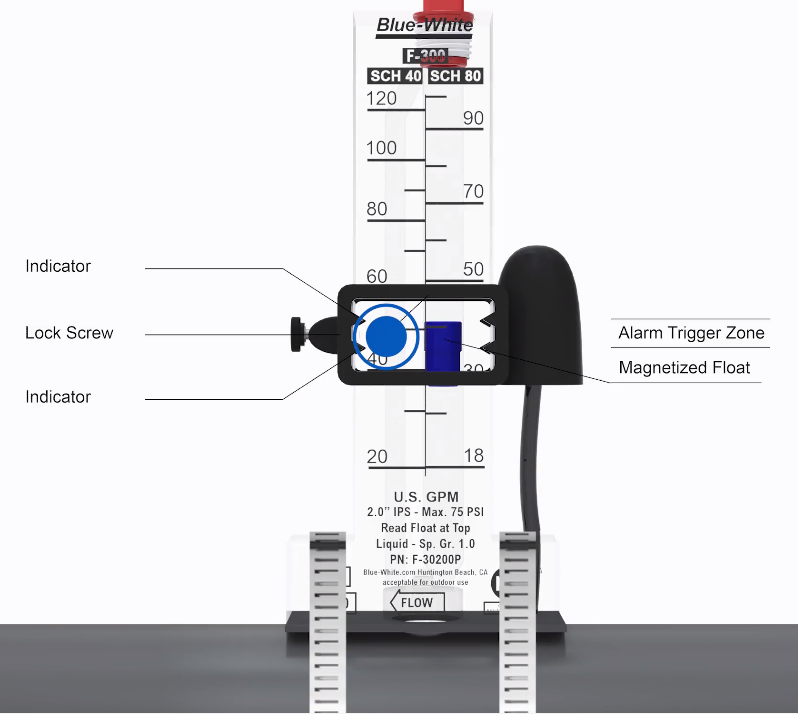

The F-300S flow switch/sensor or F-300SL flow switch/sensor can be installed at a targeted flow rate and can detect if the flow is within the desired flow range.

- Detect if the water flow rate is at the desired level

- If the flow rate is within the selected range, a built-in contact closure switch can remotely turn on/off a chemical pump and other external devices

- It can be used as an alarm signal to detect if the flow rate is not within the desired range

- F-300S / F-300Sl comes with a yellow float. To install the yellow float, remove the top cap, remove the red float, place the yellow float into the body with the wider diameter at the top, and thread the red cap back onto the flow meter.

- Easily install the F-300s /F-300SL switch by lowering it over the top of the flowmeter. Confirm you have the correct switch for the flow meter / pipe size. (F-300SL for 1” – 1.25”P, F-300S for 1.5” – 4”P)

- Tighten the Lock-Screw at the desired flow level.

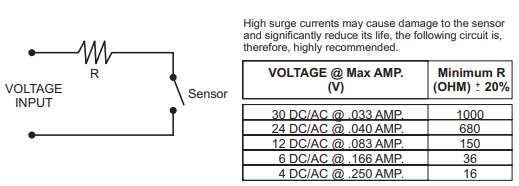

- Wiring is simple normally open, form A, SPST, contact closure wiring (see F-300 specifications for details)

- Keep wiring clear of pump power wiring and VFD wiring.

FAQs

Frequently Asked Questions

F-300 Installation

- What is the F-300S flow switch and sensor? How does it work?

The F-300S Flow Switch/Sensor is designed to detect flow or no flow. When the PVDF float passes through the Alarm Trigger Zone of the sensor accessory, the built-in contact closure switch sends a signal to external devices.

The pitot tube bottoms out in pipe. What causes this?The F300 meter may be intended for a different pipe size. The meter may not be installed perpendicular to the centerline of the pipe.

Can my flowmeter be installed on a different pipe size than what it was intended?No, the F-300 meter is pipe size specific. The model number indicates the pipe size type it was designed for.

Can I leave the meter installed outside over the winter?If installed outside, we recommend removing the meter from the pipe and storing it indoors for the winter. While the meter can withstand cold temperatures and outdoor conditions, expansion and contraction caused by freezing water can cause stress to the meter components that might result in cracking. Clean the meter inside and out prior to re-installing the meter.

- Ask me a question!

Copyright © 2024 Blue-White

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Request a quote

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|