Industrial

F-300

Product Specifications

Meter Ranges

| Model | Pipe Size | Flow Rate (GPH) | Flow Direction | |

| Sch 40 | Sch 80 | |||

| F-30100P | 1” | 5 to 35 | 4 to 26 | Horizontal |

| F-30125P | 1-1/4” | 9 to 50 | 8 to 40 | Horizontal |

| F-30150P | 1-1/2” | 10 to 70 | 10 to 60 | Horizontal |

| F-30200P | 2” | 20 to 120 | 18 to 100 | Horizontal |

| F-30250P | 2-1/2” | 29 to 150 | 25 to 130 | Horizontal |

| F-30300P | 3” | 45 to 240 | 40 to 215 | Horizontal |

| F-30400P | 4” | 75 to 420 | 70 to 375 | Horizontal |

| F-30600P | 6” | 170 to 1100 | 160 to 1000 | Horizontal |

| F-30800P | 8” | 300 to 2200 | 275 to 1950 | Horizontal |

| U-30150P | 1-1/2” | 10 to 60 | 10 to 50 | Up |

| D-30150P | 1-1/2” | 10 to 60 | 10 to 50 | Down |

| U-30200P | 2” | 20 to 110 | 20 to 100 | Up |

| D-30200P | 2” | 20 to 110 | 20 to 100 | Down |

| Model | Pipe Size | Flow Rate (LPM) | Flow Direction | |

| PN 10 | PN 16 | |||

| F-30032M | 32mm | 30 to 150 | 30 to 310 | Horizontal |

| F-30040M | 40mm | 70 to 310 | 60 to 270 | Horizontal |

| F-30050M | 50mm | 50 to 350 | 50 to 300 | Horizontal |

| F-30063M | 63mm | 100 to 475 | 75 to 400 | Horizontal |

| F-30075M | 75mm | 150 to 700 | 150 to 600 | Horizontal |

| F-30090M | 90mm | 200 to 850 | 200 to 800 | Horizontal |

| F-30110M | 110mm | 600 to 1800 | 550 to 1600 | Horizontal |

| U-30050M | 50mm | 100 to 450 | 100 to 400 | Up |

| D-30050M | 50mm | 100 to 450 | 100 to 400 | Down |

| U-30063M | 63mm | 175 to 675 | 150 to 600 | Up |

| D-30063M | 63mm | 175 to 675 | 150 to 600 | Down |

Pipe Requirements: IPS inch pipe size (ASTM-D-1785), Metric pipe size (DIN 8062)

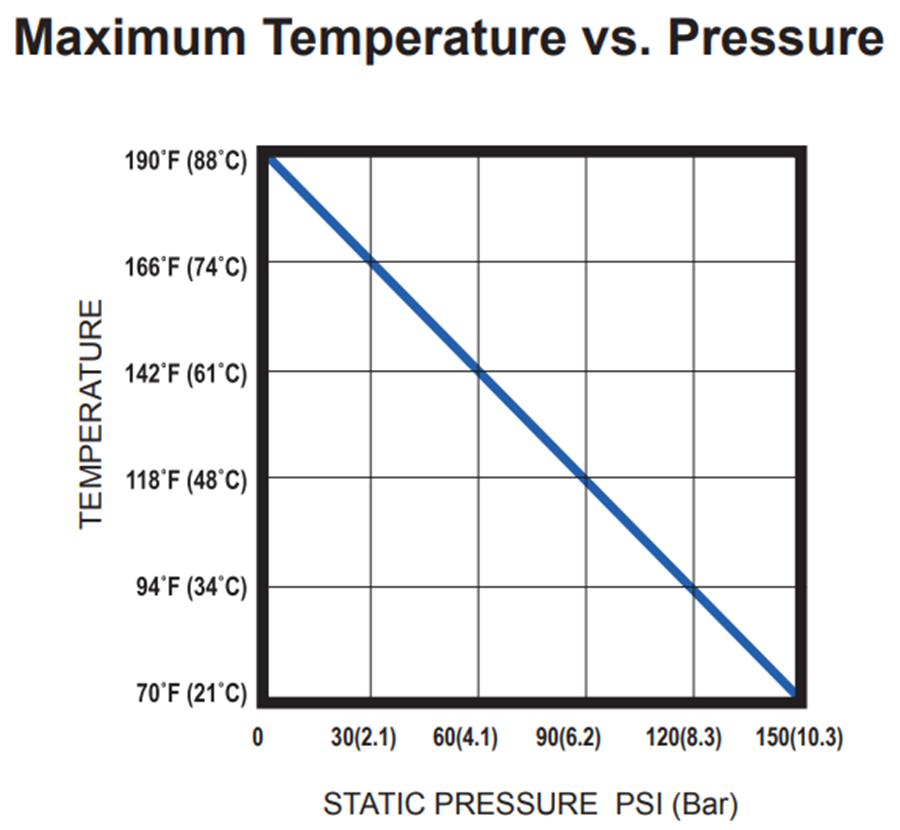

Maximum Working Pressure: 50 PSI (3.4 bar) at 70 ˚F (21 ˚C) F-300 Units, 75 PSI (5.2 bar) at 70 ˚F (21 ˚C) U/D-300 Units.

Fluid Temperature Range: 0˚ to 190 ˚F / -18 to 88 ˚C @ 0 PSI

Ambient Temp Range: 0˚ to 110 ˚F / -18 to 43 ˚C

Full Scale Accuracy:

- 1”, 1.25”, 1.5” and 2” pipe size: 5%

- 2.5”, 3”, 4”, 6”, and 8” pipe size: 10%

Calibration Fluid: Water, specific gravity 1.0

Approximate Shipping Weight:

- 1” – 4” units: 1 lb (.45kg)

- 6” – 8” units: 2 lb (.91kg

Wetted Components

- Meter Body: Acrylic

- Float: PVDF

- Gasket: Neoprene

- Pipe Clamp: 316SS

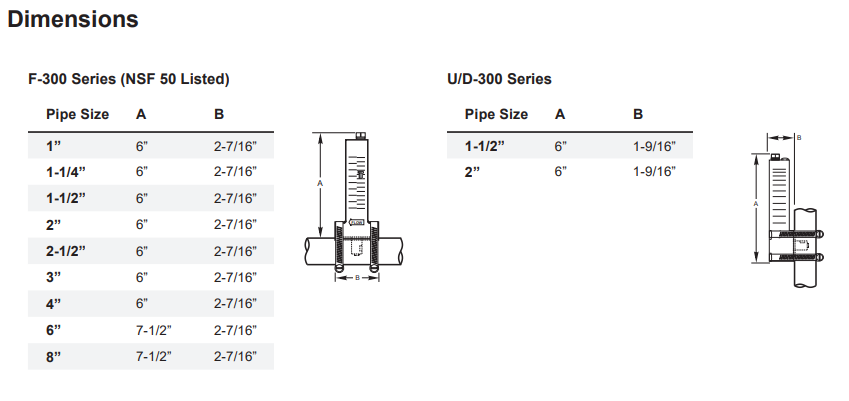

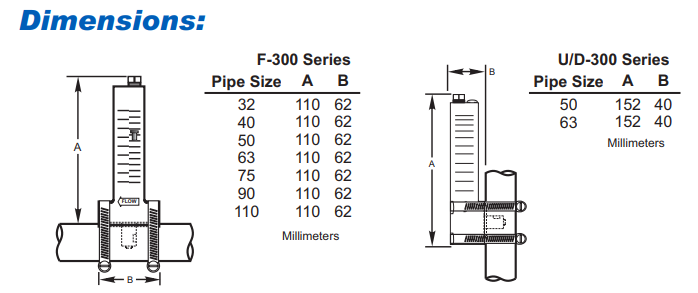

Dimensions and Weights

Maximum Overall Dimensions: 2-7/16” W x 6” H (1” – 4” units), 2-7/16” W x 7-1/2” H (6”, 8” units)

Temperature vs. Pressure

Agency Listings

NSF 50 Listed

F-300S /F-300SL Sensor/Switch Specifications

Voltage

- 100 VAC or VDC Abs. Max.

Current

- 0.250 Amp AC/DC Abs. Max.

Power

- 5 Watts Max.

Contact Configuration

- N.O.

Form

- A, SPST

Housing Material

- PVDF, Black

Load Type

- 5 feet, 24 wire

FAQs

Frequently Asked Questions

F-300 Product Specifications

- The meter should be +/- 5% accuracy. But my reading appears to be off by 15%. Why?

The meter's accuracy statement is that the indicated reading on the meter will be within 5% of the maximum flow rate scale number on the meter (full scale accuracy statement). For example, if the maximum possible reading of the meter (maximum scale number) is 200 GPM, the indicated reading at any point on the meter can be plus or minus 10 GPM, which is 5% of the maximum reading of 200 GPM, and still be considered reading within the accuracy statement. Thus, in this example, if the meter is indicating 80 GPM, the actual flow rate could be anywhere between 70 and 90 GPM.

Is the F300 series NSF listed?Yes, NSF/ANSI 50 - Equipment for Swimming Pools, Spas, Hot Tubs and Other Recreational Water Facilities

Is F300 available with metric LPM scale ranges?Yes, the F-300 is available with LPM flow ranges for metric pipe PN10 OR PN16 in, sizes 32mm, 40mm 50mm 63 mm 75mm 90 mm & 110mm

What models are designed for vertical pipe installations? My pipe size is larger than D & U 300. What can I use instead?The D-300 and the U-300 series is designed for vertical pipe installations. D= Downward flow direction U= Upward flow direction. Available pipe sizes are 1.5" & 2" only. For vertical pipe installations larger than 2", we suggest the appropriate F1000 RB digital paddlewheel flowmeter. This series can be installed on horizontal or vertical pipe.

My meter has a silver 316 ss float. I see the current models have red floats. Are the floats interchangeable between old & new models?The silver float is designed for use in the original F300 which have the GPM and LPM scale flow ranges. The Red float is designed for the new models with sch 40 and sch 80 GPM scales. The floats are not interchangeable.

Can I use the F-300 on pipes other than schedule 40 or schedule 80?Mounting the meter on pipe sizes other than schedule 40 or schedule 80 may result in pitot tube interference or inaccurate readings and is not recommended. The meter's calibration is based on the exact inside diameter of the pipe.

The F-300 can be mounted on metal or plastic pipes with a relatively smooth surface. To operate properly and to prevent leaking, the meter must only be mounted on smooth surface pipes of the specified outside diameter pipe size. The pipe's "schedule" indicates the wall thickness of the pipe and therefore defines the inside diameter and pressure capability.

Models with a suffix letter "P" (example: F-30200P) are calibrated for schedule 40 and schedule 80 metal or plastic U.S. pipe sizes (I.P.S. Iron Pipe Size) only. Models with a suffix letter "M" (example: F-30090M) are calibrated for PN10 and PN (Pressure Nominale) metal or plastic pipe sizes (Metric Pipe Size) only.

What does “pressure and temperature limits are inversely proportional?”This means that as the fluid temperature increases, the maximum pressure capacity decreases by a proportional amount, and as the system pressure increases, the maximum temperature capacity decreases by a proportional amount.

What will my accuracy be if I install the F-300 without the recommended straight length of pipe before and after the meter?The F-300 meter requires a relatively uniform flow velocity profile across the flowing section of pipe. A straight length of pipe before and after the meter is needed to reduce flow profile distortions such as swirl patterns and secondary axial flow patterns caused by elbows, valves, and other types of disturbances. Because these flow patterns will change as the flow rate (velocity) changes, it is impossible to calculate error, and therefore the accuracy of the meter, under these conditions.

Processing... ...- Ask me a question!

×This chatbot is powered by Oswald AI Technology. To chat with a Blue-White representative please use our live chat or visit blue-white.com/contact-us

Copyright © 2024 Blue-White

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Request a quote

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|