Industrial

A-100NFP

Installation

What’s in the Box

The A-100NFP Pump is shipped with the following contents:

- A-100NFP Peristaltic Metering Pump

- Two tube assemblies (1 installed, 1 spare)

- Discharge injection fitting with check valve

- Suction tube – clear PVC – 5′ length (3/8″ OD, 1/4″ ID)

- Suction strainer

- Suction ceramic weight

- Discharge tube – opaque polyethylene – 5′ length (3/8″ OD, 1/4″ ID)

- Mounting hardware kit

- Shroud (weatherproof cover)

- Power Cord (if ordered)

Preparation

The A-100NFP Pump is designed to withstand outdoor conditions, although it is recommended to locate the pump in a protected enclosure for maximum pump life. A cool, dry location where the unit can be easily monitored is recommended.

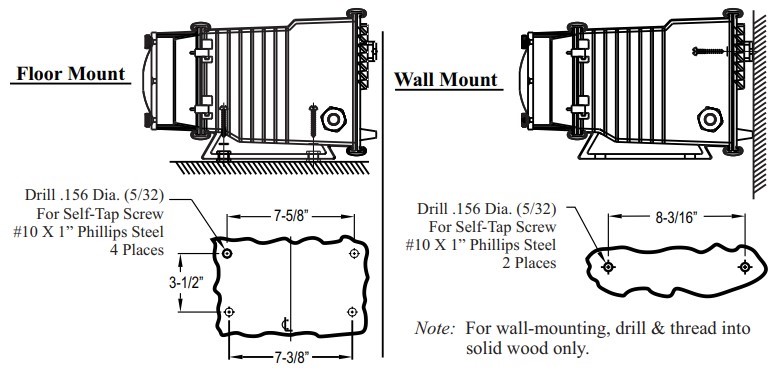

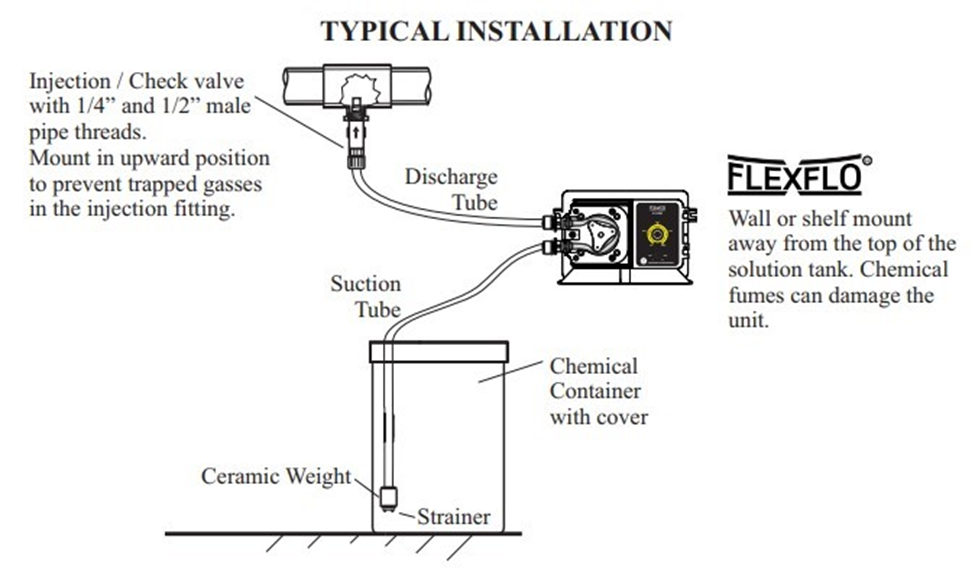

The pump can be mounted on a level, flat surface, or the pump can be wall-mounted. Blue-White also offers a sturdy polyethylene (PE) <a href="https://www.blue-white.com/product/wall-mount-kit-1-2-3-4-series/" target="_blank" rel="noreferrer noopener">Wall Shelf</a> to mount the pump.

Piping and Physical Installation

The A-100NFP Pump must be level to ensure pumping accuracy.

If mounting the pump to the wall using the provided wall bracket, follow these instructions:

- Use the diagram and drawing on the manual (or below) to mount the bracket to a secure wall location. We recommend mounting the pump at a height where the display and indicator lights are easily visible, and where it can be easily serviced.

- Mount the pump close to the injection point.

- Mount the pump to the side or lower than the chemical tank.

- Mounting the pump lower than the chemical container will gravity-feed the chemical into the pump. This “flooded suction” installation will reduce output error due to increased suction lift. You must install a shut-off valve, pinch clamp, or other means to halt the gravity feed to the pump during servicing.

Connecting Suction and Discharge Tubing/Piping

A-100NFP Pump tube elements have 1/4’” x 3/8” tubing connections (designated by “T” in the pump or tubing part number.)

The pump will come with suction and discharge tubing, suction strainer, and discharge injection valve.

Before connecting the tubing to the pump, be sure the pump is OFF. Wear protective clothing and eye protection when connecting tubing to chemicals or chemical lines.

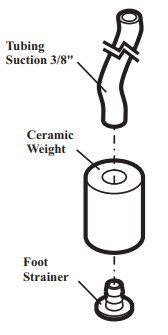

Connect the suction tubing to the pump, and place and secure the other end of suction tubing in the chemical tank/source. Using the provided foot valve/strainer and weight is recommended.

Strainer. – Trim the inlet end of the suction tubing so that the strainer will rest approximately two inches from the bottom of the solution tank. This will prevent sediment from clogging the strainer. Slip the ceramic weight over the end of the suction tube. Press the strainer into the end of the tube. Secure the ceramic weight to the strainer. Drop the strainer into the solution tank.

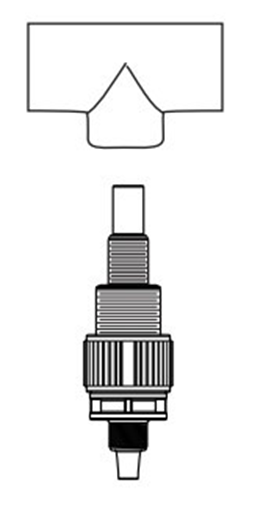

Connect the discharge tubing to the pump and then connect the other end to the discharge point. If using the provided injection valve, be sure to mount it in an upward position to prevent air bubbles from collecting.

Note: We highly recommend installing a check valve on the discharge side of the pump. The check valve can be in the form of an injection check valve, in-line check valve, quick disconnect check valve, or similar. When there is a tube leak, the check valve will prevent chemicals from the discharge line from continually feeding into the pump head.

Wiring

Power Wiring

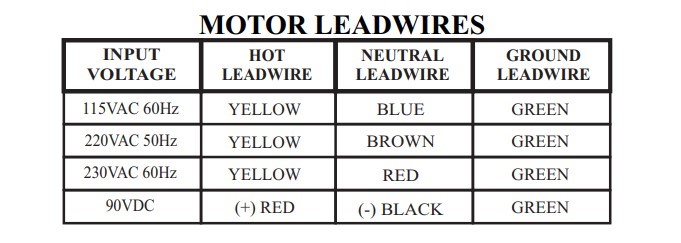

The A-100NFP can be powered by the following power sources:

- 115VAC/60Hz, 1ph (.51 amp max)

- 230VAC/60Hz, 1ph (.56 amp max)

- 220VAC/50Hz, 1ph (.66 amp max)

- 240VAC/50Hz, 1ph (.58 amp max)

Use the provided 6’ power cord, or an appropriately protected IEC C13 cord rated at 250 volts.

- Be sure to connect the pump to the proper supply voltage. Using the incorrect voltage will damage the pump and may result in injury. The voltage requirement is printed on the pump serial label.

- The pump is supplied with a ground wire conductor and a grounding-type attachment plug (power cord). To reduce the risk of electric shock, be sure that the power cord is connected only to a properly grounded, grounding-type receptacle.

- Note: When in doubt regarding your electrical installation, contact a licensed electrician.

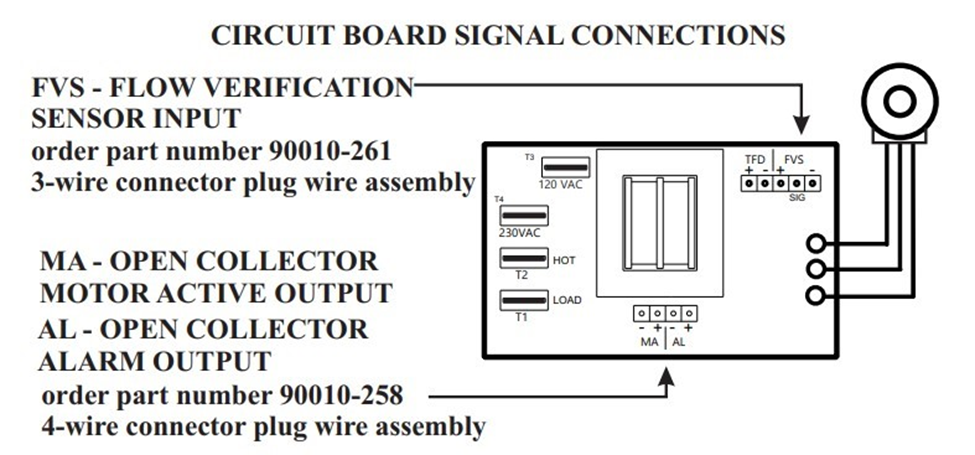

Optional Signal Wiring

The pump includes three optional external signal connections:

FVS – FLOW VERIFICATION SENSOR INPUT Accepts a pulse signal from an optional Blue-White sensor confirming that fluid is passing through the pump. Triggers the AL alarm output if fluid is not detected.

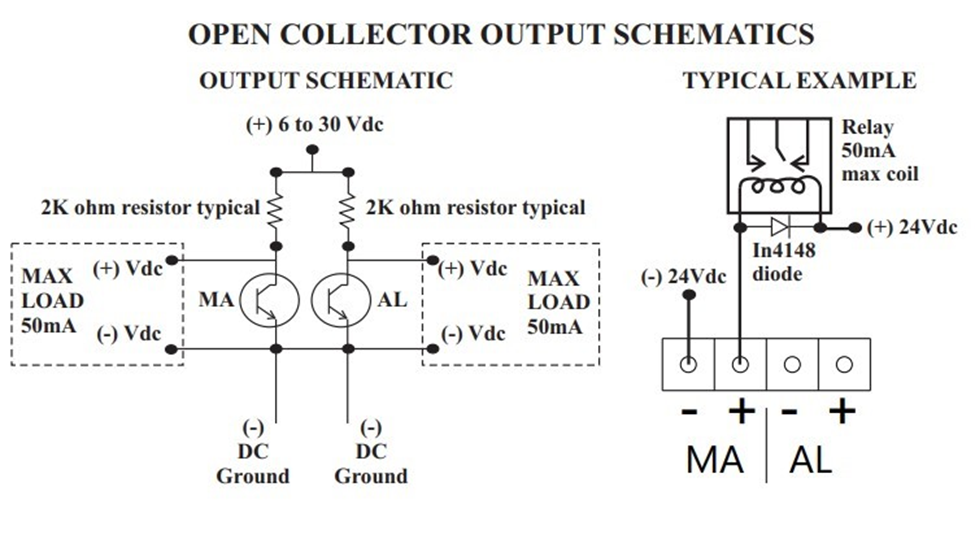

AL – ALARM OPEN COLLECTOR OUTPUT The output (purple wire) sinks to DC ground when an alarm condition exists. 6-30Vdc collector voltage. 50mAdc maximum sinking current.

MA – MOTOR ACTIVE OPEN COLLECTOR OUTPUT The output (brown wire) sinks to DC ground when the motor is de-energized. 6-30Vdc collector voltage. 50mAdc maximum sinking current.

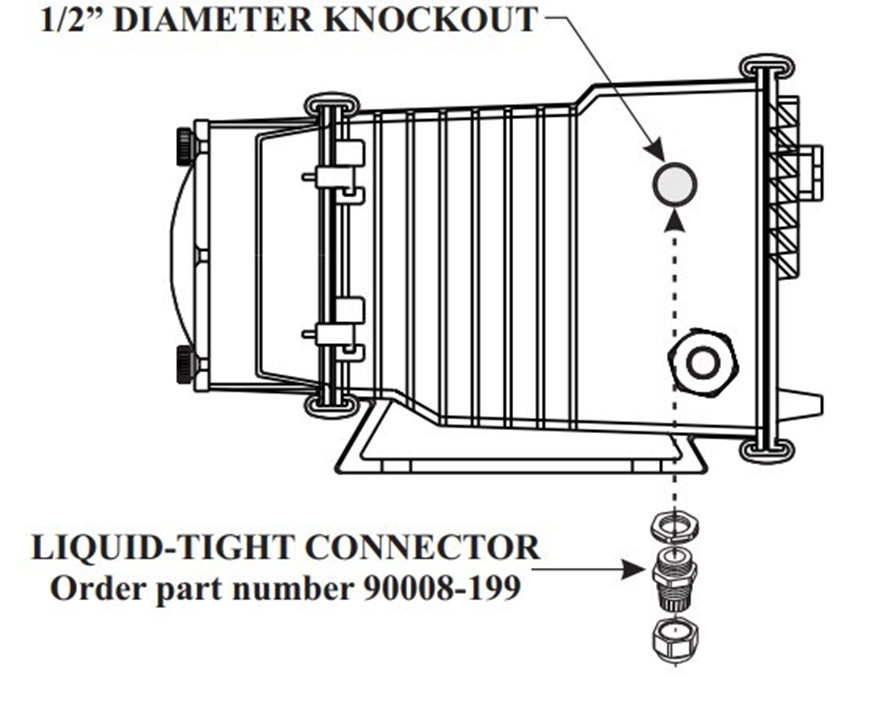

All signal wires must be connected to the circuit board, located inside the pump enclosure, using connector plug wiring assemblies. A liquid-tight connector must be installed in the pump enclosure wall and the signal wires passed through the liquid-tight connector and secured.

- Remove the rear enclosure panel.

- Remove knock-out using a screwdriver.

- Trim edge with a knife and remove sharp edges.

- Install the provided liquid-tight connector.

- Connect the connector plug to the circuit board.

See the below Wiring Chart for information and specifications in connecting to your electrical and control system.

| Circuit Board Signal IN/OUT Connections | |

| SYSTEM DESCRIPTION | WIRE COLOR CODE |

| FVS – FLOW VERIFICATION SENSOR INPUT Accepts a pulse signal from an optional Blue-White sensor confirming that fluid is passing through the pump. Triggers and alarm output if fluid is not detected. | RED (+ 20VDC) BLACK (-) YELLOW (signal) |

| TFD – TUBE FAILURE DETECTION SYSTEM INPUT Monitors a pair of sensors in the pump head. Triggers an alarm output if fluid with a conductivity of greater than 500 micro-Seimens is detected. Typical chemicals include chlorine, acid, and caustic. The system will not detect water or silicone lubricating oil. | GRAY & GRAY |

| AL – ALARM OPEN COLLECTOR OUTPUT The output (purple wire) sinks to DC ground when an alarm condition exists. 6-30Vdc collector voltage. 50mAdc maximum sinking current. | PURPLE (+) & BLACK (-) |

| MA – MOTOR ACTIVE OPEN COLLECTOR OUTPUT The output (brown wire) sinks to DC ground when the motor is de-energized. 6-30Vdc collector voltage. 50mAdc maximum sinking current. | BROWN (+) & BLACK (-) |

When wiring Open Collector Motor On Output, refer to the below schematics:

Refer to the instructions in the manual for detailed information.

FAQs

Frequently Asked Questions

A-100NFP Installation

- Why do I need to install a back flow prevention check valve?

Install a back flow prevention check valve at the discharge side of the pump to prevent the system fluid from flowing back through pump during tube replacement or during tube rupture.

Do I have to used PTFE thread seal compound? Or can i use any type of thread seal compound?Any thread seal compound can be used but the following should be taken into consideration when choosing:

- The type of fluid that will be carried in the pipe. If the fluid is corrosive, you will need to choose a sealant that is resistant to that particular type of corrosion.

- The pressure that will be applied to the pipe. If the pipe will be carrying high-pressure fluids, you will need to choose a sealant that is designed for high-pressure applications.

- The temperature of the fluid that will be carried in the pipe. If the fluid will be hot, you will need to choose a sealant that is designed for high-temperature applications.

- The cost of the sealant. Thread sealants can range in price from a few dollars to several hundred dollars. It is important to choose a sealant that fits your budget.

Can I use any size suction and discharge tubing? or any brand I want?Suction and discharge tubing must be 1/4″ ID x 3/8″ OD compatible with compression fittings connections and must be compatible with solution being pumped. Tubing can be acquired from any provider. The A-100NFP pump is shipped with 5” of PVC suction tubing and 5“ of Polyethylene discharge tubing.

What is FVS? What does it do, what are use cases?FVS is an acronym meaning Flow Verification System. Blue-White offers two types of Flow Verification Sensors, the MICRO-FLO FV series paddlewheel sensor, and the MS6 and S6A series ultrasonic sensors. These chemical flow sensors are designed to output an electrical signal when chemical is moving through the sensor. Many Blue-White metering pumps are capable of receiving this signal which then verifies that chemical has actually been dispensed from the pump.

- Ask me a question!

Copyright © 2024 Blue-White

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Request a quote

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|