Industrial

A-100NVP

Operation

Priming the Pump

Before priming the pump, or starting the pump, be sure that all suction and discharge lines are connected properly and that proper valves are open.

Pressing the Run/Standby and Field buttons at the same time will start the pump at 100% speed and will run for 99 seconds. The pump can be stopped at any time by pressing the Run/Standby button. All 99 seconds may not be required to prime the pump. Conversely, if additional priming is necessary, the process can be repeated.

If the pump does not prime, check the suction line for clogs, obstructions, or leaks. Make sure all appropriate valves are open.

Manual Operation – Mode 1

To run the pump in Manual Mode, ensure the “MODE 1” is displayed. Or toggle Mode button until “MODE 1” is displayed. Press the Run/Standby key to start the pump running. Adjust pump speed by programming (see Set-Up and Controls section). To stop the pump, press the Run/Standby key.

4-20ma Input Speed Control – Mode 2

To run the pump in 4-20mA Mode, press the Mode button until “MODE 2” is displayed. Press the Run/Standby button to start the pump. Pump speed will be set by remote 4-20mA input signal. To toggle/view either % motor speed or 4-20 mA signal, press the Digit and Mode keys at the same time. To stop the pump, press the Start/Stop key.

0-10 VDC Input Speed Control – Mode 3

To run the pump in O-10 VDC Mode, press the Mode button until “MODE 3” is displayed. Press the Run/Standby button to start the pump. Pump speed will be set by remote 0-10 VDC input signal. To toggle/view either % motor speed or 0-10 VDC signal, press the Digit and Mode keys at the same time. To stop the pump, press the Start/Stop key.

Frequency (Hz) Input Speed Control – Mode 4

To run the pump in Frequency Mode, press the Mode button until “MODE 4” is displayed. Press the Run/Standby button to start the pump. Pump speed will be set by remote Hz input signal. To toggle/view either % motor speed or Hz signal, press the Digit and Mode keys at the same time. To stop the pump, press the Start/Stop key.

Calibration

To ensure the most accurate pumping, a pump calibration is recommended prior to operating the pump. The A-100NVP pump flow rate will vary depending on the suction line conditions. Calibrate the pump with actual suction line conditions.

To calibrate the pump:

- Connection tubing and open valves on the suction side of the pump to represent actual suction lines conditions.

- Set up discharge and open discharge valves to dispense into calibration column/cylinder.

- Prime to the pump so that the calibration column begins to fill. Stop the pump and note the solution level in the calibration column.

- Run the pump at a set speed for 1 minute.

- Record the flow difference in the calibration cylinder.

- Calculate the flow rate by dividing the flow by the time. For example, if the pump runs for 1 minute, and the flow difference is 30 ml, then divide 30ml by 1 minute. The flowrate is 30 ml/min.

- For best accuracy, run more than one calibration to check results, or run another calibration at a different pump speed.

Calibration results should be similar to the flow rating for the pump tube, but can vary depending on chemical composition, suction lift, viscosity, temperature, and other conditions.

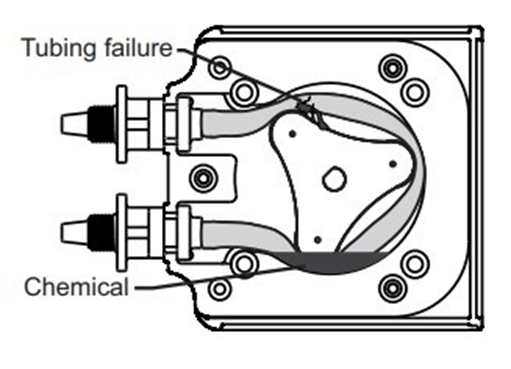

Tube Failure Detection (TFD+)

The A-100NVP pump is equipped with a corrosion-resistant TFD+ leak-detection located inside the pump head. If a tube fails or leaks for any reason, the polymer or chemical will trigger the sensor, stop the pump, and activate an alarm.

If TFD+ alarm occurs, the pump will stop, close an alarm output, and the screen will display “Alarm”. The TFD+ can detect the presence of non-conductive chemicals, such as oil-based polymers, water-based polymers, or other oils.

If the system has detected a leak, the pump tube must be replaced and the pump head and roller assembly must be thoroughly cleaned. Remove the front cover to replace the tube and roller. Failure to clean the pump head properly will void the warranty.

See video on proper tube replacement. https://www.youtube.com/watch?v=NqhrR2Vs1OI&t=69s

Confirm Detection

To determine if your chemical will be detected by the system, remove the pump tube and roller assembly. Place a small amount of the chemical in the bottom of the pump head – just enough to cover the sensor.

Turn on the pump – If the TFD+ system detects the chemical, the pump will stop after a five-second confirmation period and the ALARM icon will light on the display. If the TFD+ system does not detect the chemical, the pump will continue to run after the confirmation period.

Carefully clean the chemical out of the pump head, being sure to remove all traces of chemical from the sensor probes. Press the RUN/STAND-BY button to clear the alarm condition and restart the pump.

Contact Closure Alarm Output – A contact closure output (relay) is provided with the TFD+ system. The relay can be configured for normally open (factory default) or normally closed operation by properly positioning the connector plug on the circuit board.

FAQs

Frequently Asked Questions

A-100NVP Operation

- How do I reset the 500 hour service timer?

Refer to page 9 and page 18 in the manual. Press and hold run/standby button & digit buttons at the same time.

Will pump display incoming milliamp values?Yes, when in mode 2, press the digit & mode button to view the incoming mA values and corresponding motor speeds.

- Ask me a question!

Copyright © 2024 Blue-White

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Request a quote

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|