Aquatics

A1A

Troubleshooting

Common Issues

Air is entering the pump. Check suction lines to make sure all connections are tight. Check the level of the chemical tank. Remove obstructions and clean strainers.

If pumping sodium hypochlorite, natural off-gassing may occur, which will add air to the suction and discharge lines. This can accumulate when the pump is not running. The peristaltic pump will pass this off-gas through the pump without issue, eventually injecting it into the process lines. Note that until this is completely clear, the amount of chemical injected may be less than desired.

The pump is not accurate. Check the suction line and clean the strainer. Check for obstructions in suction lines, discharge lines, and injectors. Check the condition of the tube and roller. Ensure the roller is the correct match for the tube. (See Spare Parts)

The Display reads “SIG” or “SBY.” This indicates the pump is ready and waiting for a remote signal from PLC or another control system. This is normal. If the pump is not connected to a remote signal circuit, disable this function.

Electricals

The A1A will not power up. Check the power source or try a different power source. Ensure the power cable is properly inserted in the bottom receptacle of the pump.

The Remote/Signal Start/Stop is turning on/off or chattering. Check the M8 cable’s integrity and proper connection to the pump. Check that all signal cables are shielded and properly grounded. Ensure signal wiring is not located or run next to high voltage power or equipment generating EMI. Ensure power wiring to the pump is clean/conditioned.

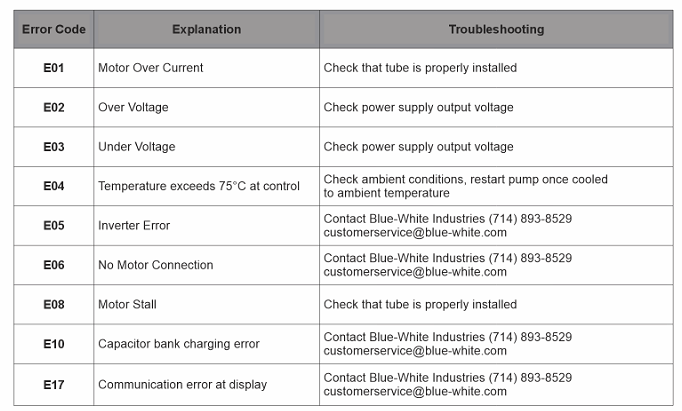

The Display reads “E04” or other error code. See the below chart and contact the factory for assistance. Some error codes are corrected with a current Firmware Update. See the System section for details on firmware updates.

FAQs

Frequently Asked Questions

A1A Troubleshooting

- Does this pump have error codes to help with trouble shooting?

E01 Motor Over Current Check that tube is properly installed

E02 Over Voltage Check power supply output voltage

E03 Under Voltage Check power supply output voltage

E04 Temperature exceeds 75°C at control Check ambient conditions, restart pump once cooled to ambient temperature

E05 Inverter Error Contact Blue-White Industries (714) 893-8529 techsupport@blue-white.com

E06 No Motor Connection Contact Blue-White Industries (714) 893-8529 techsupport@blue-white.com

E08 Motor Stall Check that tube is properly installed

E10 Capacitor bank charging error Contact Blue-White Industries (714) 893-8529 techsupport@blue-white.com

E17 Communication error at display Contact Blue-White Industries (714) 893-852

- Ask me a question!

Copyright © 2024 Blue-White