Aquatics

A2A

Operation

Priming the Pump

Before priming the pump, or starting the pump, be sure that all suction and discharge lines are connected properly and that proper valves are open.

Prime mode can be started by pressing the Prime button. The pump will run at 100% speed for 60 seconds. The pump can be stopped at any time by pressing the Stop key.

Remote Start/Stop

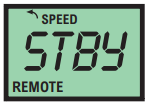

If the A2A pump has been programmed for the Remote Start/Stop feature, press the Start button to put the pump into Ready “STBY” mode. (When in Remote Mode, the display will show “REMOTE” in the bottom left corner.) The pump will run if it receives a signal. If the pump is waiting for a signal to run, it will be in “STBY” state. The display changes color and will read “STBY” if waiting for a signal from the user-provided control system. Once a signal is received, the pump will start/run.

Manual Speed Adjust

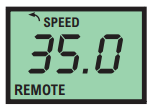

The only operating mode of the A2A pump is “Manual Speed Adjust.” Adjust pump speed by pressing the Up and Down arrow keys.

Tube Failure Detection (TFD) and Tube Information

The A2A pump is equipped with leak-detection located inside the pump head. If a tube fails or leaks for any reason, the chemical will trigger the sensor, stop the pump, and activate an alarm. Chemicals must have a conductivity greater than 500 microsiemens.

If a TFD alarm occurs, the pump will stop, close an alarm output, and the screen will flash with a red alarm and “TFD”. If the system has detected a chemical, the pump tube must be replaced, and the pump head and roller must be thoroughly cleaned.

Remove the front cover to replace the tube and roller. Failure to clean the pump head properly will void the warranty. See video on proper tube replacement.

At any time, the “tube info” button can be pressed to access pump run hours.

- Ask me a question!