Municipal

M2

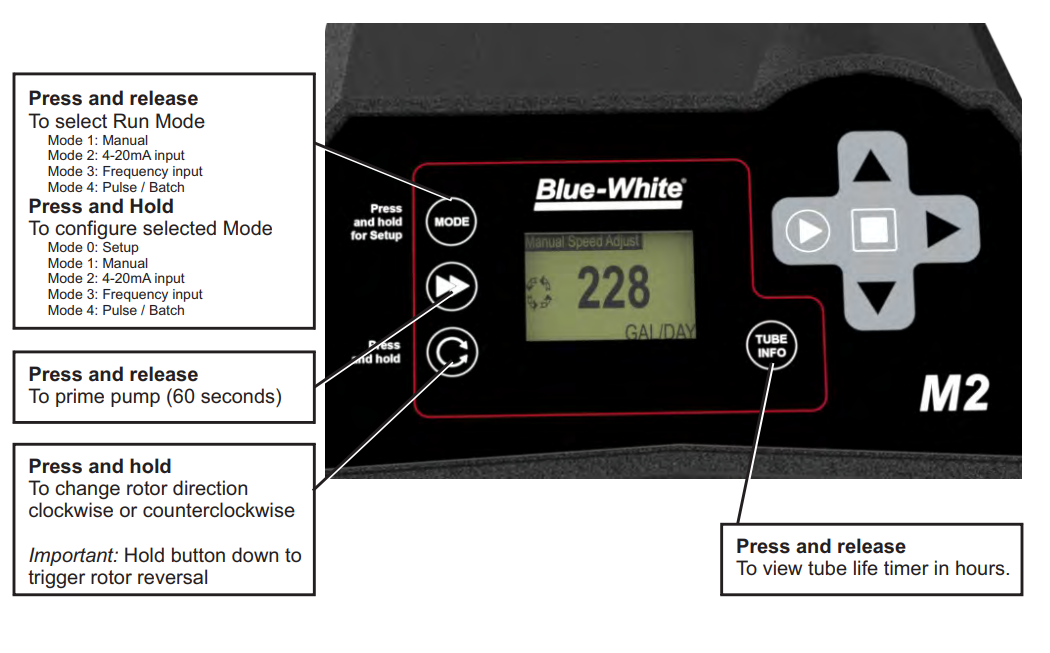

Set-Up and Controls

Powering On the M2

The M2 is powered on when plugged into the power source. The pump will take approximately 10 seconds to power on, boot, and be ready for service.

The M2 pump Main Screen will appear when powered on, showing pump status, operating mode, and any alarm or errors.

Display and Layout

The M2 has a 9-button LCD display that is easy to read and simple to use.

All pump settings can be configured by pressing the Mode button and using the other buttons to navigate. See Control Panel – Button Operation display below.

The M2 Pump has the following Control Buttons:

MODE – Press to scroll through run Mode. Press and Hold to configure pump.

MODE – Press to scroll through run Mode. Press and Hold to configure pump.  PRIME – Press to prime the pump at full speed for 60 seconds.

PRIME – Press to prime the pump at full speed for 60 seconds.  ROLLER ROTATION – Press to change direction of roller rotation.

ROLLER ROTATION – Press to change direction of roller rotation.  START – Press to Start pump.

START – Press to Start pump.  STOP – Press to Stop pump.

STOP – Press to Stop pump.  RIGHT ADVANCE – When in the Configuration – used to select items and advance to next setting.. When on main screen – used to toggle through display of flow units or incoming signal units.

RIGHT ADVANCE – When in the Configuration – used to select items and advance to next setting.. When on main screen – used to toggle through display of flow units or incoming signal units.  UP ARROW – When in Configure – used to toggle through menu items. When in Manual Speed Adjust mode – used to increase the speed of the pump.

UP ARROW – When in Configure – used to toggle through menu items. When in Manual Speed Adjust mode – used to increase the speed of the pump.  DOWN ARROW – When in Configure – used to toggle through menu items. When in Manual Speed Adjust mode – used to decrease the speed of the pump.

DOWN ARROW – When in Configure – used to toggle through menu items. When in Manual Speed Adjust mode – used to decrease the speed of the pump.

Mode and Configuration for the M2 pump

All pump settings and programming are done via the Mode Navigation. Press and hold Mode button to Configure the pump and Program inputs and outputs:

Configuration

Use the Configuration to:

- Choose Remote Start/Stop

- Set TFD Sensitivity

- Activate FVS (Flow Verification)

- Configure 4-20 mA signal output

- Choose display flow rate units (% speed, RPM, ml/min, Oz/min, Liter/Hr, Gal/Hr (US).

- Set Max Flow Rate of pump (based on tube installed in pump, and pump/tube calibration.)

Configuration Details and Set-up

When in Configuration (Mode 0) Set-up, use the right arrow button to scroll through the different configuration options.

- Remote Start/Stop. Active by choosing “Yes”. Close = Start, Open = Stop.

- TFD Sensitivity is set to 78% default. This will trigger with most chemicals, but will not trigger with tap water and condensation. Adjust sensitivity to 100% to sense water and more diluted chemicals.

- Choose to activate FVS by setting a delay time. If a FVS sensor is not used, keep this setting at 00 sec. FVS sensor is provided separately. Contact factory for sensor options.

- 4-20mA output signal is fully configurable. Default is 4 mA = 0% motor speed, 20 mA = 100% motor speed.

- Display units are selectable and will appear on the screen alternately with the flow valve. A flow unit must be chosen/configured for flow to be displayed during operation.

- Max Flow Rate – Default value will be the maximum flow of the tube provided with the pump. This value is used by the pump when displaying active flow with units chosen on the previous setting. Adjust this value when changing tubes, or after a pump calibration.

Operating Modes (Programming)

The M2 Pump includes four (4) Operating Modes. Use the Mode button to select the Operating Mode of your choice:

- Mode 1. Manual Speed Adjust. Choose pump speed at the pump by using up or down buttons.

- Mode 2. 4-20 mA. Pump will run at a speed proportional to the 4-20ma signal.

- Mode 3 Frequency. Pump will run at a speed proportional to the Frequency signal (0-1000Hz.)

- Mode 4. Pulse Batch. Pump will run for a set time and speed when the pump receives a programmed number of pulse signals.

To program/configure a Mode, hold the Mode button for 5 seconds while in the Mode. This will activate programming for that Mode. Follow the steps for programming each Mode. Refer to the M2 Manual for more details.

Pump Output Setup

The M2 Pump includes output signals for monitoring pump status and alarms. Use the Output Setup to program the following:

- 4- 20 mA Signal Output. Used to send scaled output signal related to pump speed (flow) to a SCADA system.

- Motor On/Off Output. Contact closure output when motor is running.

- Motor speed. Open Collector output.

- Output Alarm. One Relay output will trigger with TFD or FVS alarm.

Additional System Settings (Pump Tube Info, Power Fail, Maintenance Mode)

The M2 Pump has a pump Tube Info button. Tube Info gives the operator hours used. Typical reset when tube is changed.

The M2 Pump will resume running operation when power is returned after power failure.

The M2 pump will go into Maintenance Mode whenever the front cover is removed. The screen will read “FVS”. Pump is equipped with a sensor on the cover. The pump will run at a maximum of 6 rpm when in maintenance mode.

- Ask me a question!