Municipal

M3

Installation

What’s in the Box

The M3S Pump is shipped with the following contents:

- M3S Multi-Diaphragm Metering Pump

- Two tube assemblies (one installed, one spare)

- Tube installation tool

- Power Cord (if ordered)

- USB Drive (Operating manual)

- Mounting hardware kit (includes standard mounting brackets, extened mounting brackets, and hardware.)

- Suction strainer, PVDF (with “S”, “M”, and “B” tube connectors only)

- Discharge injector, PVDF/Aflas with 1/2 psi check (with “S”, “M”, and “B” tube connectors only)

- Any tubing, injection valves, foot valves / strainers are not included with the M3S pump.

Preparation

The M3S Pump is designed to withstand outdoor conditions, although it is recommended to locate the pump in a protected enclosure for maximum pump life. A cool, dry location where the unit can be easily monitored is recommended. Special ventilation is not required.

The pump can be mounted on a level flat surface. We recommend using the provided mounting brackets for secure installation. Blue-White also offers a sturdy polyethylene (PE) <a href="https://www.blue-white.com/product/wall-mount-kit-1-2-3-4-series/" target="_blank" rel="noreferrer noopener">Wall Shelf</a> to mount the pump.

Piping and Physical Installation

The M3S Pump must be level to ensure pumping accuracy.

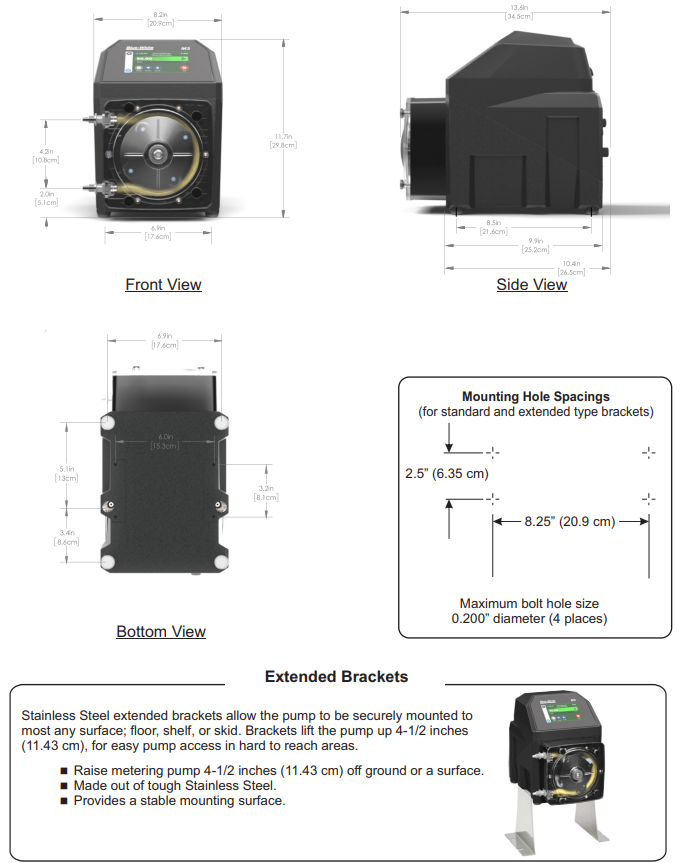

If mounting the pump using the mounting bracket, follow these instructions:

- Use the diagram and drawing on the manual (or below) to mount the pump and bracket to a secure location. We recommend mounting the pump at a height where the display and indicator lights are easily visible, and where it can be easily serviced.

- Ensure the bracket is mounted to the pump first using the provided hardware. (Standard and extended brackets attach to pump using same hardware, and hole dimensions are the same.)

- Ensure location provides enough space for inlet and outlet connections to the pump, and ensure enough space for rear wiring.

- Place the pump and secure to the base surface using the appropriate hardware for the base surface.

If mounting the pump to a shelf, be certain the shelf will be able to support the weight of the pump.

Connecting Suction and Discharge Tubing/Piping

M3S Pump tube elements have six (6) options for connections.

“S” 1/4’” x 3/8” tubing connections. When M3S pump is ordered with “S” tubing connections, it will come with Injection Check Valve, Suction Strainer, 10 feet of 1/4” x 3/8” clear PVC suction tubing, and 10 feet of 1/4” x 3/8” polyethylene discharge tubing.

“M” 1/2” MNPT connection. When M3S pump is ordered with “M” tubing connections, it will come with Injection Check Valve, and Suction Strainer. Tubing or piping not included.

“B” 1/2” Hose Barb connection. When M3S pump is ordered with “B” tubing connections, it will come with Injection Check Valve, and Suction Strainer. Tubing/hose or piping not included.

“C” Tri-Clamp connection. When M3S pump is ordered with “C” tubing connections, it will not come with Injection Check Valve, Suction Strainer, or tubing.

“Q” Quick Disconnect (Quick disconnect fittings provided separately). When M3S pump is ordered with “Q” tubing connections, it will not come with Injection Check Valve, Suction Strainer, or any tubing. Quick Disconnect fittings must be ordered separately (see accessory options.)

“MB” 1/2” Male BSPT connection. When M3S pump is ordered with “MB” tubing connections, it will not come with Injection Check Valve, Suction Strainer, or any tubing.

Connecting Suction and Discharge Tubing for “S” connection

Before connecting the tubing or piping to the pump, be sure the pump is OFF. Wear protective clothing and eye protection when connecting tubing to chemicals or chemical lines.

Connect the suction tubing to the pump, and place and secure the other end of suction tubing in the chemical tank/source. Using the provided foot valve/strainer and weight is recommended.

Connect the discharge tubing to the pump and then connect the other end to the discharge point. If using the provided injection valve, be sure to mount it in an upward position to prevent air bubbles from collecting.

Note: We highly recommend installing a check valve on the discharge side of the pump. The check valve can be in the form of an injection check valve, in-line check valve, quick disconnect check valve or similar. When there is a tube leak, the check valve will prevent chemicals from the discharge line to continually feed into the pump head.

Wiring

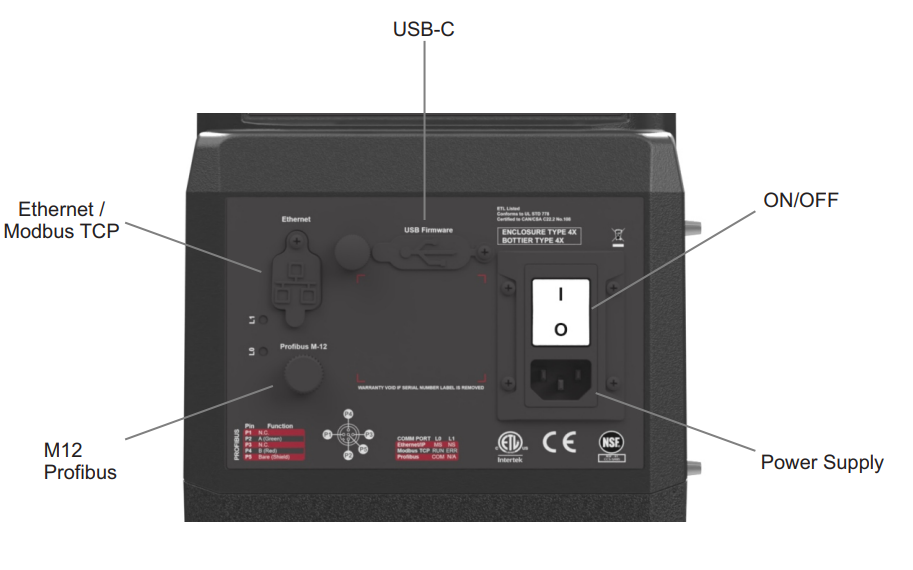

Power Wiring

The M3S is powered by 100 to 240VAC, 50/60Hz power. Use the provided 6’ power cord, and attach the cord at the back of the pump.

A removable power cord is included if the pump is ordered with either a “4” 115V 50/60Hz-NEMA 5/15 plug(US), or a “5” 220V 50/60Hz-CEE 7/V11plug. See accessories for alternate power cord options (ordered separately.) If using a power cord not provided by Blue-White, the cord must be IEC C13 rated at 250 volts.

Caution: Consult a licensed electrician when in doubt about your electrical installation.

Control Wiring

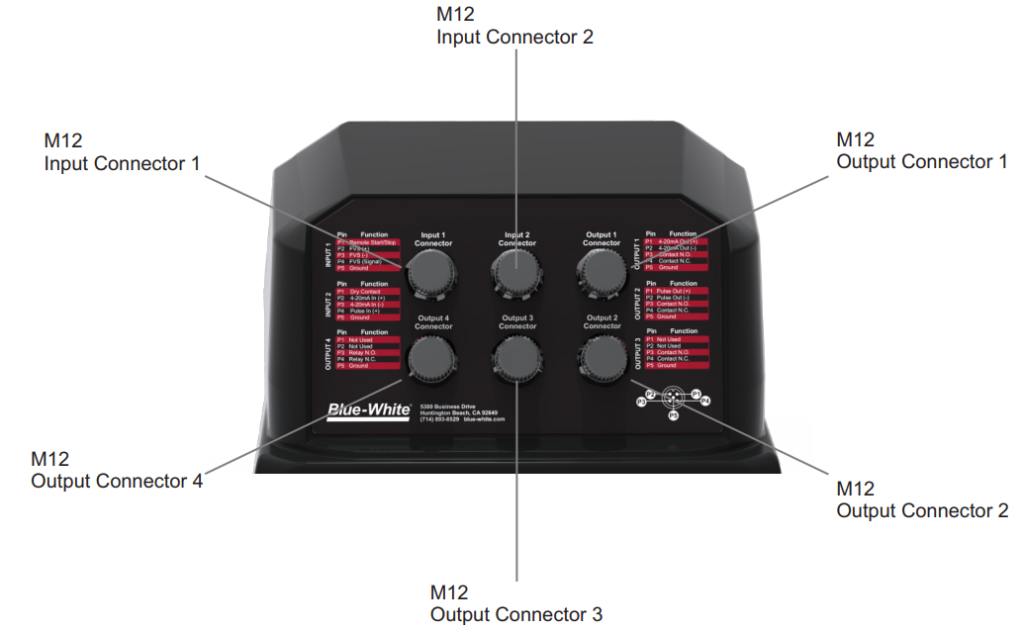

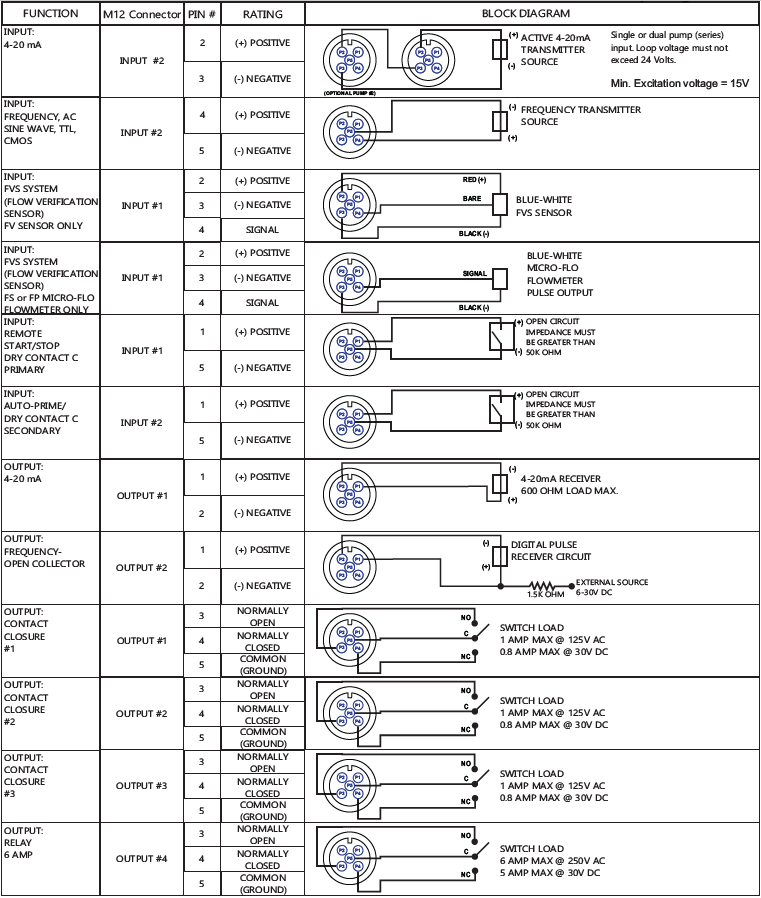

The M3S pump has six (6) M12 male connectors (5 pin) on the back of the pump for connection to signal wiring.

Connection to the M12 connectors must be accomplished with shielded and insulated M12 cables with a 250VAC voltage rating. (M12 cables are not included with the pump. See accessories or purchase separately.)

Signal connection includes:

Input Signals

- Remote Start/Stop Input (Dry Contact Closure)

- Auto-Prime (Secondary Input – Dry Contact)

- FVS (Flow Verification System) Input

- 4-20mA Input (pump speed control)

- Frequency / Pulse Input (AC, Square Wave)

Output Signals

- 4-20 mA output (Pump speed – scalable)

- (3) Output Alarms (Contact closure rated 1 amp, 125VAC) (Programmable)

- (1) Output Alarm (Relay, 6 amp (250VAC) or 5 amp (30 VDC) (Programmable)

- Pulse Output 0-1000Hz (AC, Square Wave)

Communications Wiring

- Ethernet and Modbus connections are made via the Ethernet port on the rear of the pump.

- Profibus connection is made via the M12 Profibus connector at the rear of the pump.

See the below rear panel images and Wiring Chart for information and specifications in connecting to your electrical and control system.

Note: Shielded cables must be used on all signal wiring.

Refer to the instructions in the manual for detailed information.

FAQs

Frequently Asked Questions

M3S Installation

- The warning states, “Risk of electric shock – All wiring must be insulated and rated 300V minimum.” Is the M12 cable rated for 300V? What is the rating?

M12 cables provided by Blue-White are rated for 250V.

This power cord does not appear to be able to withstand water, rain, hose down, etc. Can it? Is there any literature or evidence that it can?The A3, A4, M3, and M4 model chemical metering pumps incorporate an attached power inlet cord with liquid-tight strain-relief connector that have been tested by independent testing labs and passed NEMA 4X, IP66 hosedown/washdown test requirements. The A3S, A4S, M3S, M4S, and M5 model chemical metering pumps incorporate a power inlet module with power switch. These models have also been tested by independent testing labs and passed NEMA 4X, IP66 hosedown/washdown test requirements. The power inlet module is designed to meet IP67 protection against the effects of immersion in water between 15cm and 1m for 30 minutes. The power entry module combines an IEC appliance inlet with an integrated rocker style circuit breaker helping to prevent accidental manipulation. The module features a first-of-its-kind IP67 sealed version according to IEC 60529.

Can I use the MS6 or S6A meter as an FVS? how do I wire this?Yes, the MS6 or S6A can be used as an FVS for the M3/M4 legacy pumps or the M3S/M4S pumps.

Are shielded cables “required” or just recommended? what will happen if I used a non-shielded cable?Shielded cables are required on all signal wiring to ensure consistent and reliable communication between pump and control system.

How does “flooded suction” installation reduce output error due to increased suction lift?Suction conditions will affect output on peristaltic pumps. A suction lift will derate flow by a percentage related to the amount of suction lift. A "flooded suction" or "positive pressure" on the suction side of the pump will minimize or eliminate derated flow conditions.

Can this pump be installed in direct sunlight?Yes, the legacy M3 and the M3S can be installed in direct sunlight.

- Ask me a question!

Copyright © 2024 Blue-White

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_85334924_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

Request a quote

Please fill out the form to request a quote.

A sales rep will reach out to you.

| Image | Catalog Number | Description | Price | Buy |

|---|