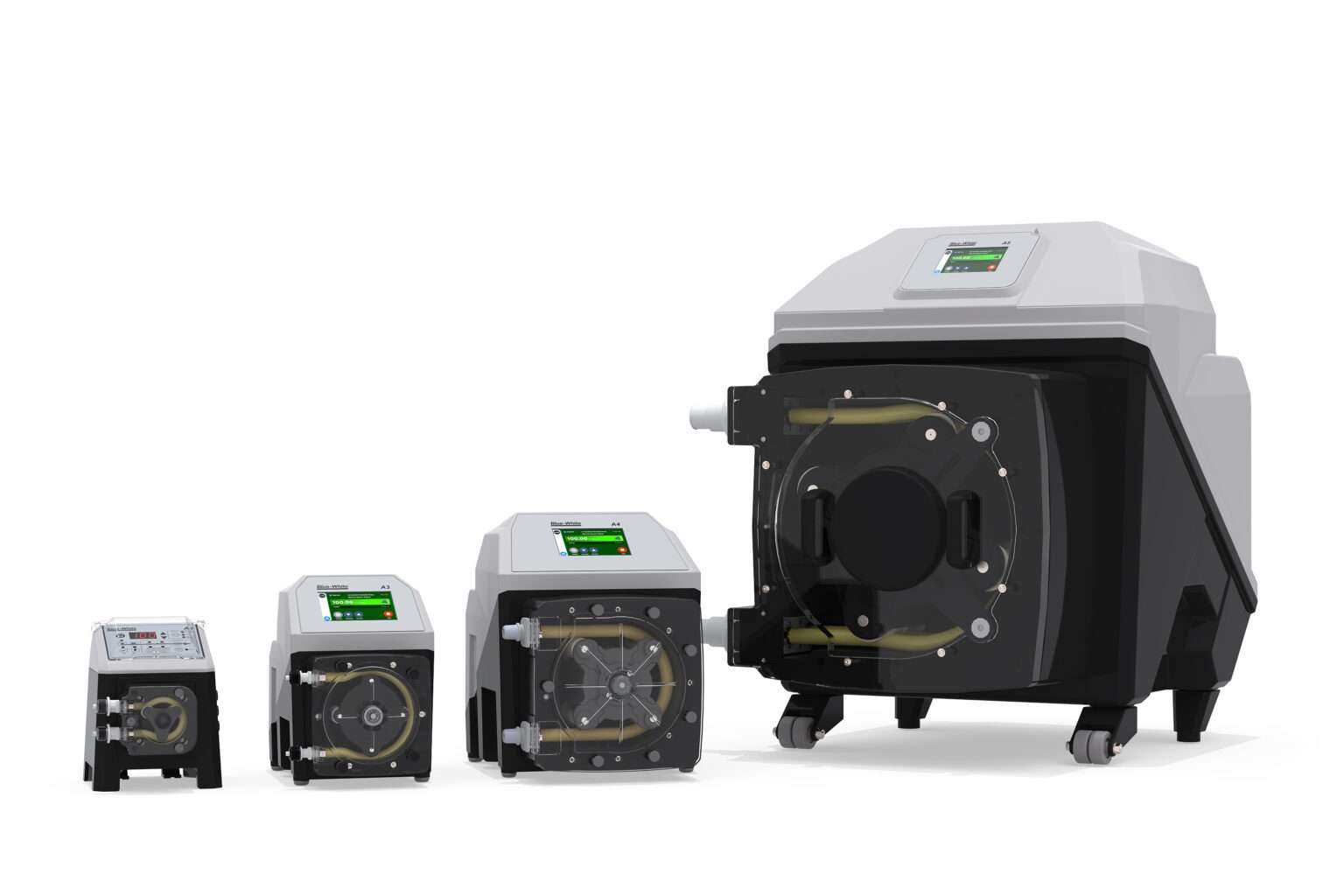

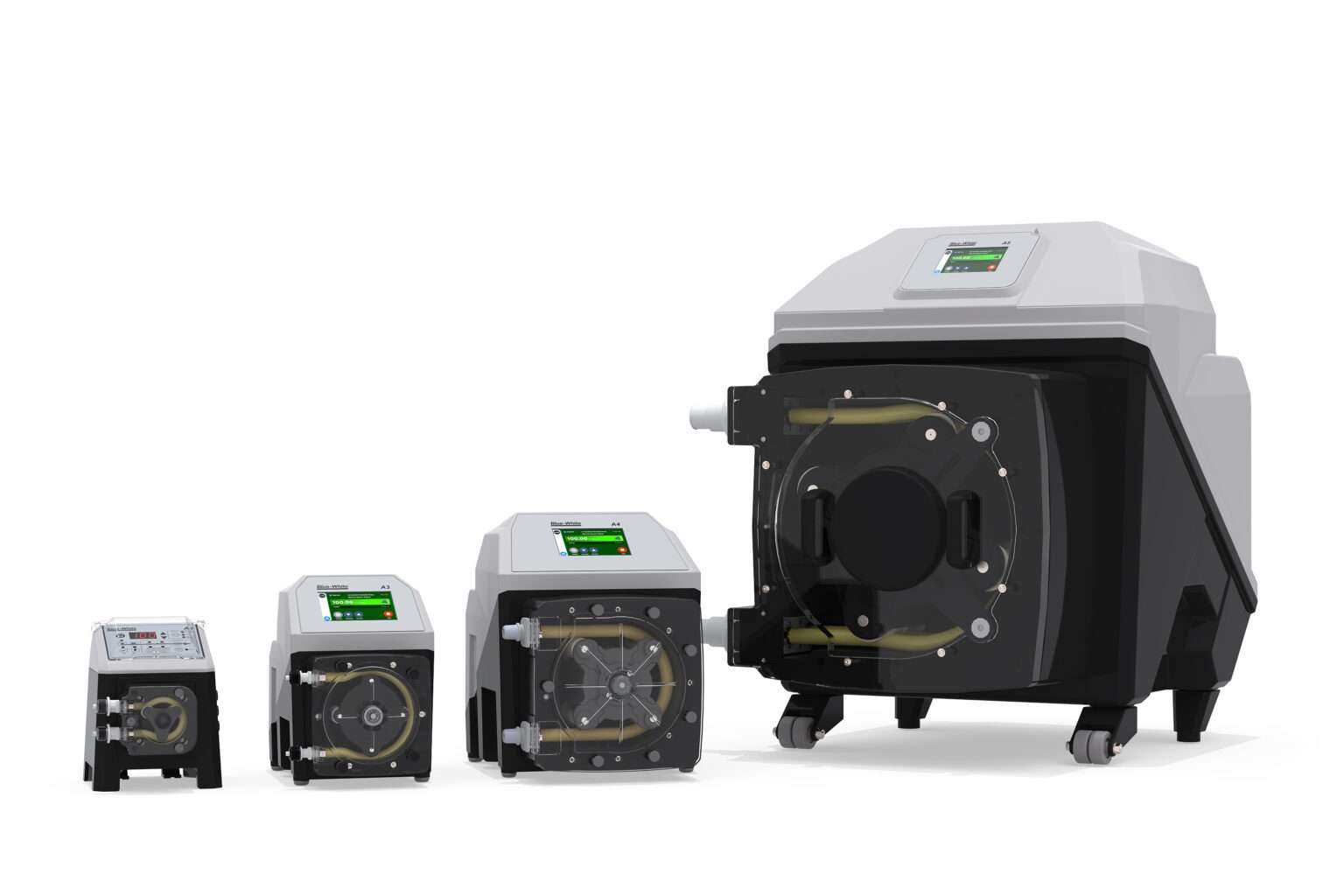

Industrial Peristaltic Pumps

Blue-White® Industrial Peristaltic Pumps

Blue-White’s FLEXFLO® Peristaltic Metering Pumps (Peristaltic Dosing Pumps) deliver precision fluid metering and accurate dispensing with a wide range of control capabilities. Their gentle, nearly pulsation-free pumping action makes them ideal for difficult-to-pump fluids such as gaseous chemicals, shear-sensitive fluids, viscous slurries and solids, and fluids with low moisture levels.

Explore Industrial Peristaltic Pumps

A-100N

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .1 - 5.2 | .4 - 20 |

| PSI | Bar |

| 100 | 6.9 |

A1

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .003 - 5.6 | .011 - 21.2 |

| PSI | Bar |

| 100 | 6.9 |

A2

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .02 - 17.2 | .07 - 65.1 |

| PSI | Bar |

| 125 | 8.6 |

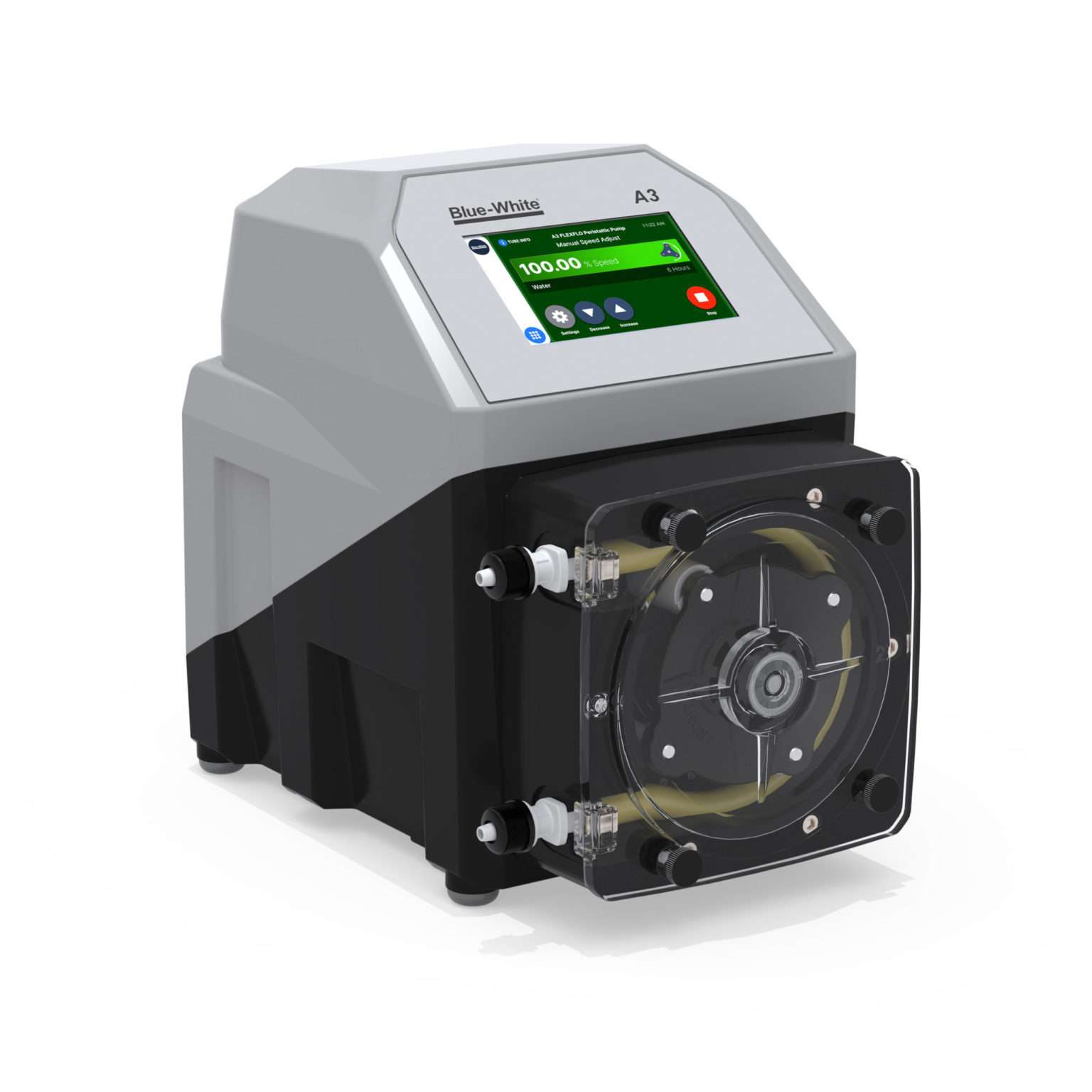

A3

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .001 - 33.3 | .003 - 126 |

| PSI | Bar |

| 125 | 8.6 |

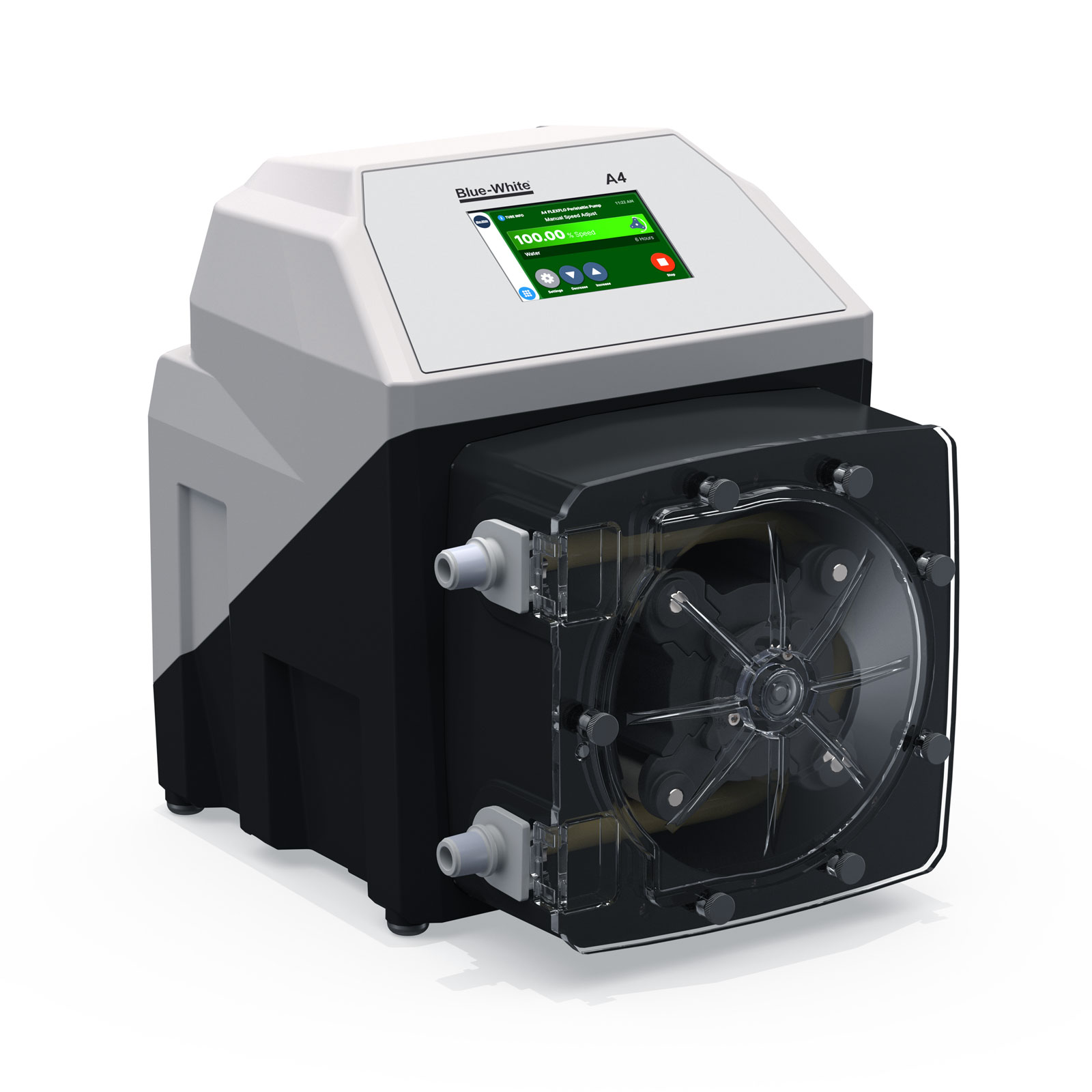

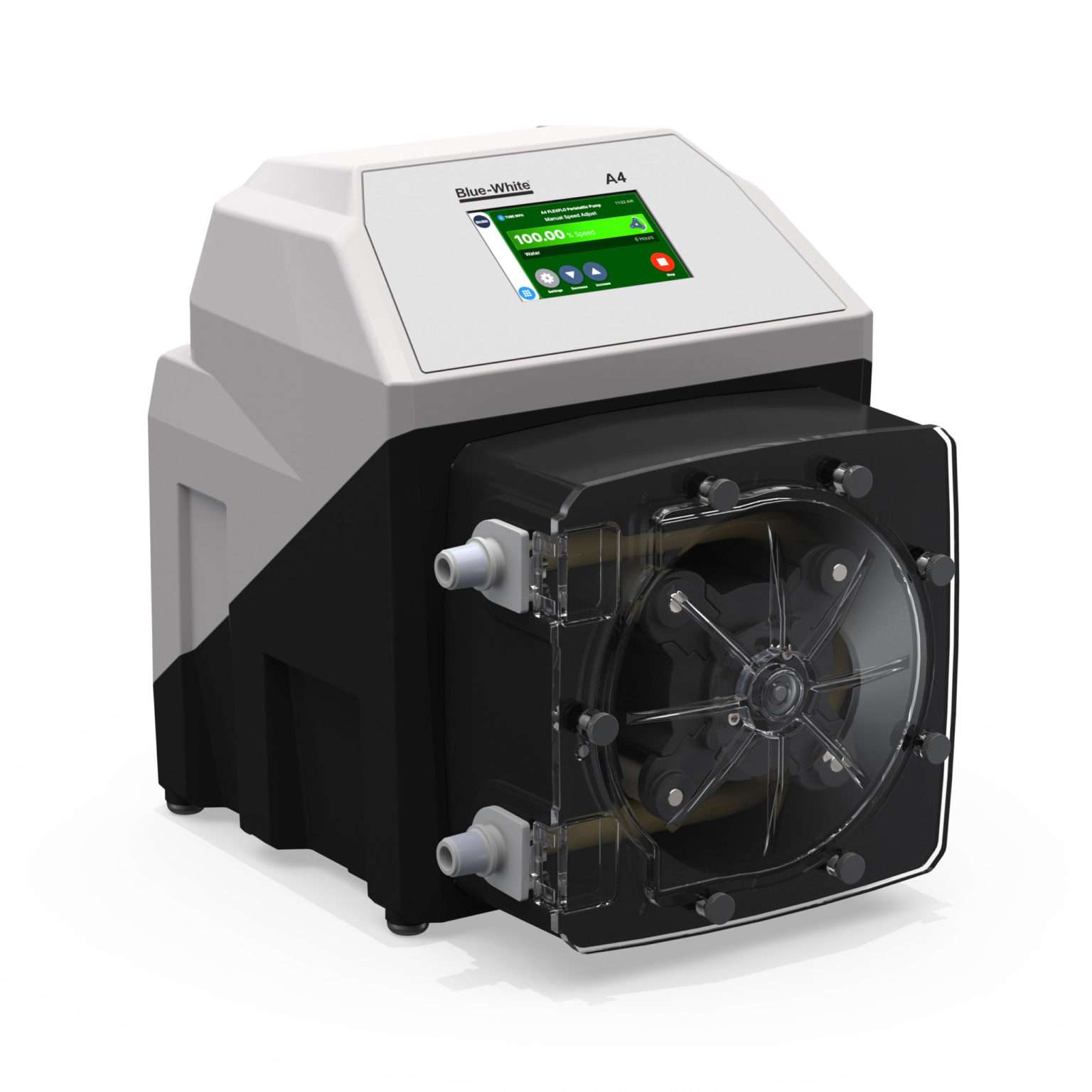

A4

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .01 - 158.5 | .04 - 600 |

| PSI | Bar |

| 125 | 8.6 |

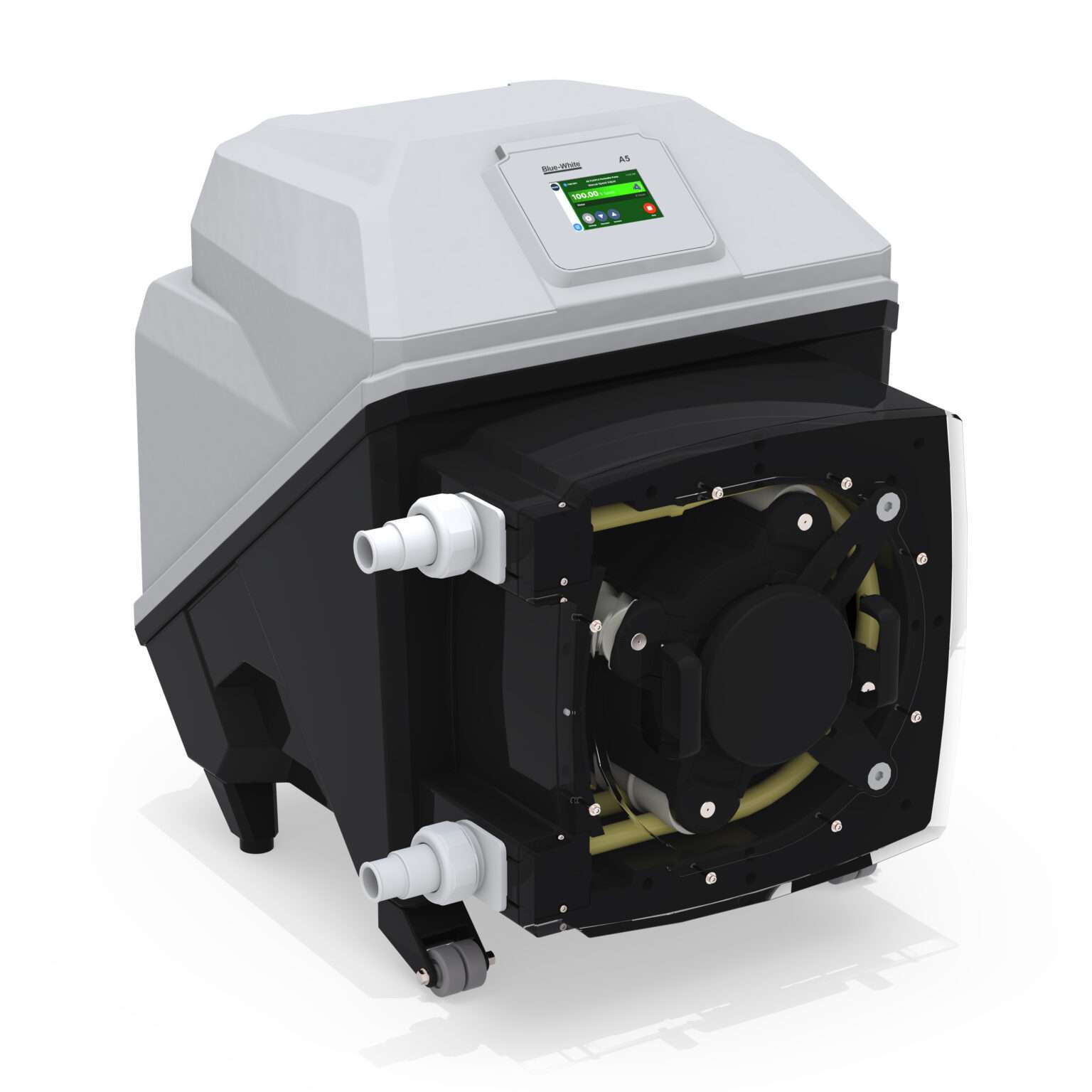

A5

FLEXFLO® Peristaltic Metering Pump

| GPH | LPH |

|---|---|

| .0302 - 534 | .1144 - 2021 |

| PSI | Bar |

| 65 | 4.4 |

Compare FLEXFLO® Features

How Do Peristaltic Pumps Work?

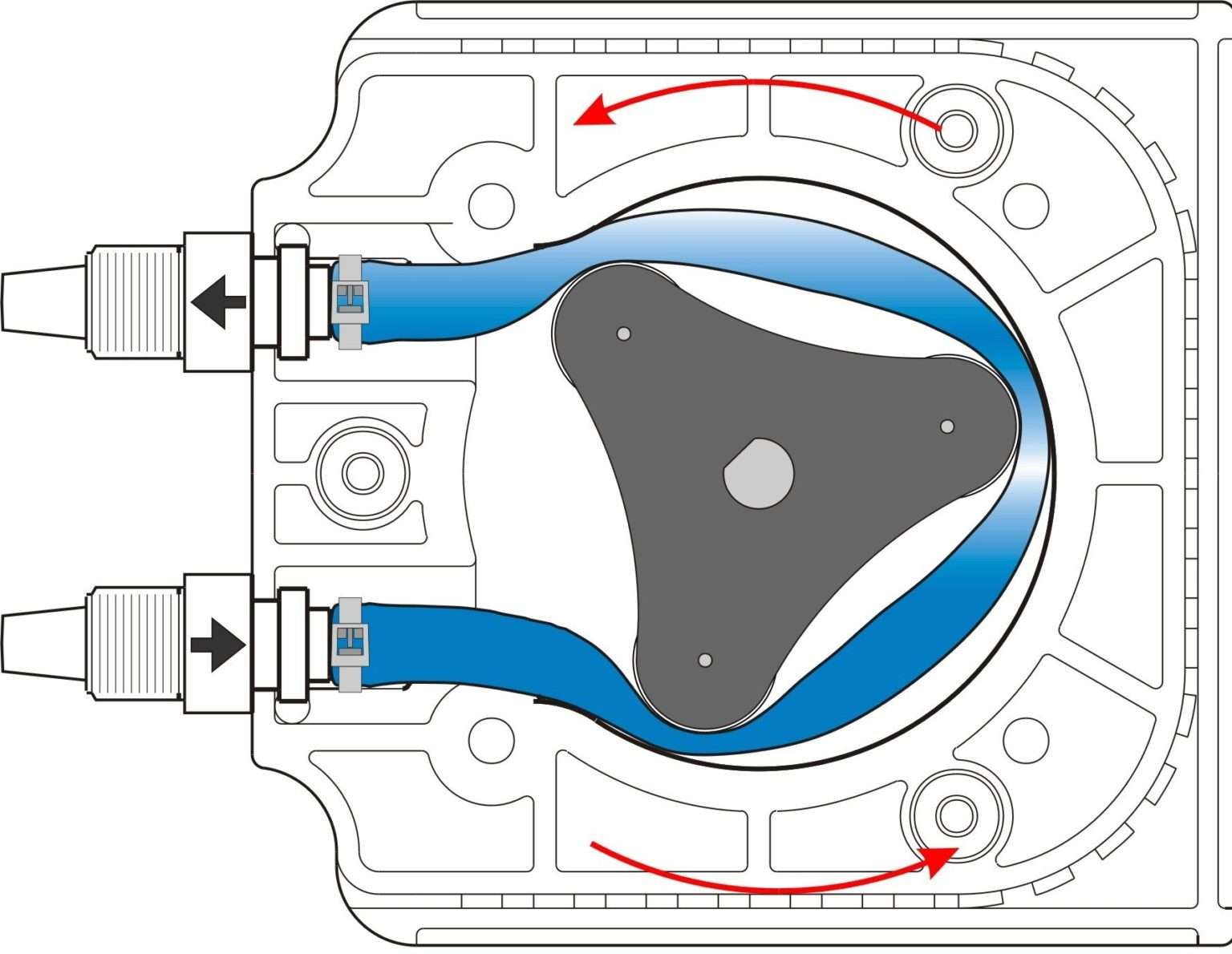

Peristaltic pumps (hose or tube pumps) are a type of positive displacement pump that work using progressive squeezing action. Fluid is pumped through flexible tubing in a peristaltic motion. As the pump’s rotor turns, the roller assembly rollers squeeze the tubing to force the fluid through the discharge line.

When the squeeze pressure is released, the tube rebounds to its original state, creating a vacuum and drawing fluid into the suction side of the pump. The combination of suction and discharge principles produces a powerful yet gentle pumping action.

Advantages of a Peristaltic Metering Pump

-

Won’t vapor lock or lose prime

Eliminate downtime and disruption in your process

-

No check-valves to clean and replace

Less maintenance and lower cost-of-ownership

-

30ft (9.1m) of suction lift

Reduce downtime with powerful suction lift capabilities

-

Gentle low-shear pumping action

Ideal for a low-shear sensitive product including flocculants

Applications

- Wastewater Treatment

- Potable Water Treatment

- Food and beverage

- Pulp and Paper

- Cooling Tower Water Treatment

- Metal Finishing

- Plastics Production

- General Chemical Metering

Explore Case Studies

Customer Testimonial

I benefit from Blue-White pumps because that’s the one part of the plant I don’t have to worry about. I have supported more than 300 plants, and I have never been called about the Blue-White pumps.

William Tait Stahl

Technical Support Manager MMBR Systems | Austin, TX